Vibrating plate repair: what to do if the tool vibrator breaks?

Vibrating plates, even when used correctly, break over time. Moreover, the main malfunctions are related to the engine. Therefore, in order to carry out vibration repair, it is important to accurately determine the cause and location of the breakdown, and then eliminate the defect. Basic recommendations and diagrams are presented in this material.

The content of the article

Main causes of breakdowns

Before you begin the repair, you need to figure out what exactly happened - for example, the vibrator or motor frame broke. Most often, breakdowns are associated with the engine, since it is the most vulnerable unit. Malfunctions may have other causes, the main ones are discussed below.

Engine breakdowns

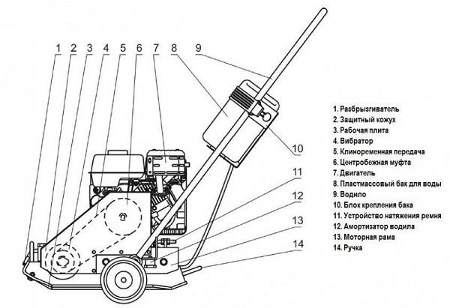

To deal with defects, it is necessary to study the structure of the vibrating plate. The diagram using an example of a gasoline model is presented below. The operating principle is related to the operation of the engine, which transmits impulse to the drive belt. Due to this effect, the exciter produces vibration, affecting the surface. At the same time, the upper and lower plates of the unit are equipped with vibration-damping fasteners, which ensures long-term operation without failures.

But sometimes the engine may fail, which may be due to various reasons (using the example of a gasoline installation):

- Poor quality oil or insufficient quantity. Because of this, the motor does not work or turns off after some time. In this case, you need to know how to disassemble the vibrator and fix the damage.

- The air filter is clogged with dirt - the engine functions, but is unstable, may lose power, and often does not start.

- Violations on the part of the spark plugs - the engine also works poorly.

- Contamination of the exhaust system.

- Piston wear.

Unit failure

You also have to figure out how to repair a vibrator if the vibration unit breaks down. In this case, the main factors are:

- the oil seal leaks, which leads to gear breakage - in advanced cases, the entire mechanism will have to be replaced;

- the engine runs at low speed;

- The drive belt is loose - just tighten it, and if it is very worn, it is easier to replace it.

Causes of smoke

Vibrator repair will also be necessary in cases where it smokes a lot. You can judge the cause of the defect by the color of the smoke:

- White – equipment is used at low temperatures, steam is generated, which is normal. But if a white smoke screen appears even when the engine is warm, it is necessary to replace the fuel - it is too wet.

- Gray or bluish, bluish smoke - oil has entered the cylinder. Or it could get into the air filter if the tool was tilted too much. Then the vibrator doesn't work.

- If the smoke is black, you need to make sure that the air damper is open. If everything is fine with it, the reason is related to the fuel system.

Vibrator repair

If the vibrator stops working, the reason may be due to a leak in the oil seal located on the shaft. Moreover, the oil begins to leak out, which leads to problems with the gears and the entire mechanism.Then a complete replacement of the unit is required.

But there are other reasons for the appearance of defects:

- If the engine is running at low speed, it is enough to increase the number of revolutions.

- If the belt is loose, tighten it or completely change it.

- If the belt is broken, you need to install a new one.

- If the engine malfunctions, the rammer, or more precisely, its drive unit, is repaired.

- It is also important to monitor the condition of the oil. If a leak occurs, the seals should be replaced as soon as possible. Thanks to this, the rest of the mechanism can be preserved.

Gasoline engine repair

Before starting repair work, it is useful to understand the structure of a gasoline vibrating plate. This is a more powerful device that is used exclusively on the street. Its malfunctions may be related to the oil, air filter or spark plugs. Basic repair methods are described in the following sections.

Oil check

If there is not enough oil, modern models lock automatically. But at the same time, you can check the level yourself. The step-by-step instructions are as follows:

- Repair of a reversible vibrating plate and other models begins with the device being installed on a flat surface.

- Then unscrew the lid.

- Lower the dipstick and check the level as shown in the diagram.

- If necessary, the oil in the vibrator of the vibrating plate is replaced.

Air filter

If the filter is clogged, it should be cleaned as quickly as possible. To do this, proceed as follows:

- Unscrew the nut and remove the cover.

- Remove another nut and take out the filter.

- Wash it with ordinary detergent, for example, dishwashing detergent. It is advisable to use warm water.

- Clean the filter element using compressed air.

- Then the mechanism is assembled and put back in place.

Checking the spark plugs

Repair of the vibrating plate vibrator is also carried out in cases where it is necessary to check the spark plugs. They may become very worn or damaged by dirt. To eliminate the defect, proceed as follows:

- Remove the spark plug using a socket wrench.

- They inspect and determine how worn it is, whether there are chips or other defects.

- If necessary, adjust the gap between the 2 electrodes.

- If necessary, replace the spark plug.

Exhaust system repair

It also happens that a gasoline rammer does not start or produces too dirty emissions. Then you need to do this:

- Unscrew the screws marked M5 and remove the casing.

- Remove the screws marked M4.

- Use a metal brush and remove dirt.

- Reassemble the mechanism and put it in place. This concludes the repair of gasoline stoves.

Electric motor repair

Repair of a vibrating plate motor begins with diagnosing the problem. The main cases are:

- If the engine does not start at all, it means that the fork or the start button is broken. The cord may have broken or the windings may have burned out. Then you should replace the corresponding unit, for example, install a new plug. If the problem is related to the windings, the entire electric motor is replaced. In case of poor contact, connect the corresponding wires.

- If the engine gets hot, it needs to be given breaks. But if this does not help, the reason may be due to poor contact in the bar. Then you need to check it. And if the surface of the windings is burnt, the unit will have to be replaced.

- It also happens that the installation suddenly stops working or moves jerkily. This is due to poor contact in the electrical circuit. Determine the right place and restore it by tightening the bolted contacts.

- Another group of malfunctions is related to the fact that the engine cannot be stopped with the start button. Then you need to replace the button or find the area where the short circuit is observed. After this, disconnect the wires and check the operation of the mechanism again.

Repairing an electrical mechanism is comparatively easier. For example, you don’t need to know what kind of oil is in the vibrator of a vibrating plate to clean it from contaminants. In addition, such a device is less noisy and can be used even indoors. However, the power of an electric unit is not as great as that of a gasoline unit.

Therefore, it is important to determine the cause before repairing. To do this, determine how much oil is in the vibrator of the vibrating plate, how the engine operates, including at the time of start-up. If you are not sure, you should seek advice from professional craftsmen. Otherwise, you can incorrectly disassemble or assemble the mechanism and damage it.