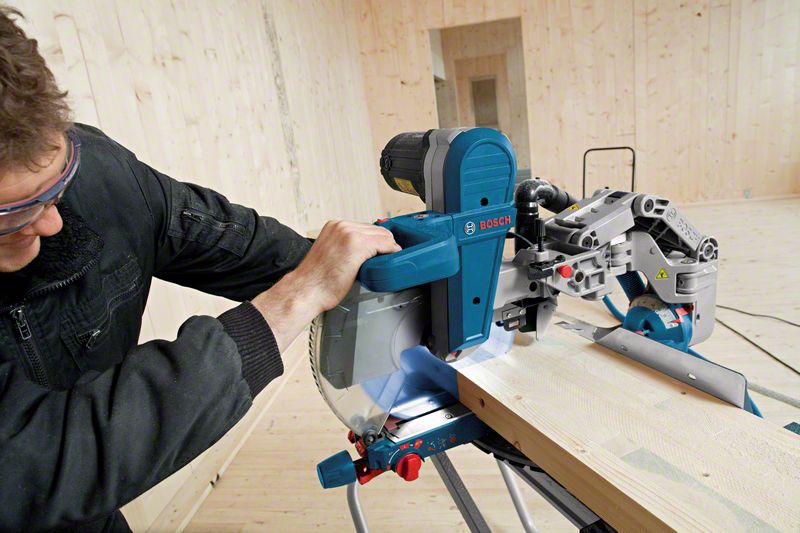

Setting up a miter saw

A miter saw is an important tool that helps make smooth and high-quality cuts on workpieces. However, accuracy can only be achieved with a well-adjusted instrument. It won't take much time and is quite easy to do with your own hands.

The content of the article

How to set up a broach miter saw?

Ensuring accuracy and proper operation of your own tool is extremely important. This must be done before the first applicationso as not to spoil the workpiece. Even the slightest deviation from the specified parameters can deform the material.

A small difference of a couple of millimeters is actually multiplied by eight times.

Good disc

If you are still using a disk installed by the manufacturer and purchased with the installation, discard it. Buy a removable, high-quality and sharp nozzle that can clearly fulfill the given conditions.

The default disk can only carry out rough cutting of wooden boards in carpentry conditions. For fine and jewelry work, you need to buy special attachments.

Buy discs with a diameter of 250–300 mm and a number of teeth of 60–80 or 80–100, respectively.

Tackle the corners

First of all, make sure that the new disc is positioned directly under the tool table. Place the tested square on the table with a block and move the disk towards it, but without touching the ruler with its teeth.Adjust the stops as specified in the manufacturer's manual.

Make sure the tilt is set to 45 degrees by doing it again after setting the scale to zero. This way your workpiece will remain in place and the cut will be smooth.

Rotation angle overlay

We install the disk at an angle of 90 degrees to the stop. If the stop is the only part, you will have to loosen the adjusting bolts, and then move the edge of the stop towards the disk on one side.

If the stop consists of two parts, one of them is adjusted at 90 degrees to the stop, and the second is aligned with the first part. It is much more convenient to do the job using a tape clamp, which quickly aligns the entire frame.

As a last resort, you can use masking tape.

Checking the result

The simplest test option is to take an unnecessary workpiece and make cuts when making a frame. Next, we join all four parts and examine the gaps that were created during the connection. If they do not suit you, start setting up again.