How to change a blade on a miter saw

Miter saw - a tool that not everyone is familiar with. It can be used for a large number of materials, but is not needed at home very often. The saw is used mainly by professional finishers. But if you plan to make repairs on your own, then it makes sense to acquire this tool to make the process easier.

In addition to mastering the operation of the device, you also need to understand its consumable parts. The main one of these elements is the cutting disc.

The content of the article

How to replace

During the repair process it may be necessary to remove the saw blade. This is not difficult to do if you know the correct sequence of actions. It is important to familiarize yourself with it for your own safety.

The replacement process begins by placing the plastic protective cover (if equipped) in the upward position. To carry out this manipulation, you need to unscrew the side auxiliary bolt, lift the structure, and then secure it with the same bolt, but in a different position.

Then:

- take a hexagon to unscrew the clamping bolt in the center;

- at the same time, on the back side of the tool, the shaft locking mechanism button is pressed - it acts as a stopper and prevents the shaft from moving;

- holding the button, you can press out the central bolt using a hexagon;

- then the bolt is unscrewed - this is easy to do by hand;

- the side stopper is removed (looks like a wide washer) and then the disk.

Installation is the reverse sequence of actions. The disk must be put on the shaft, then place the lock washer, then screw the bolt in by hand until it stops. To clamp the nozzle, press the button and hold it while simultaneously tightening the central bolt to the limit using a hexagon.

After installing the saw blade, you should check the strength of the fixation. This is done with a slight longitudinal wobble. If there is no play, then the installation was carried out correctly. You can start cutting.

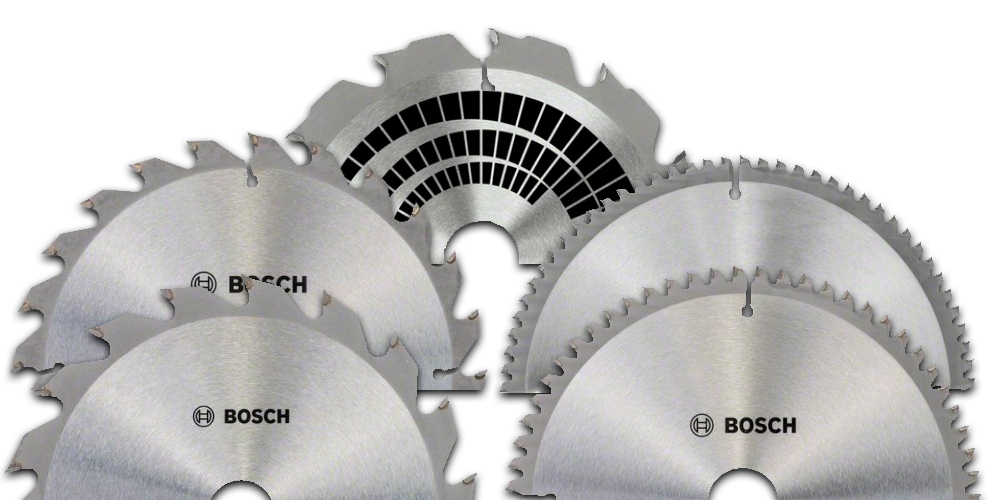

How to choose the right disk

To create modern decor, aluminum, plastic, and stone are often required. Based on this, discs are often needed to work with such materials.

Their choice for soft metals and polymers is different. Sawing a hollow structure or solid wood requires a different number of teeth on the blade. In the first case, you need a consumable part with a large number of teeth, in the second - a small toothed one.

The material and thickness of the disc are also important. The best choice is an all-alloy nozzle, the raw material for which is hard, high-carbon metal. Such a consumable spare part can be used longer and is suitable for re-sharpening. The latter is not possible if the teeth are welded.

High quality is typical mainly for European brands. The price of their products pays off during operation.

Another indicator that needs to be taken into account when choosing is the angle of inclination. For plastic, it should be negative, which allows for maximum cleanliness of sawing.

The shape of the teeth can be different. It is optimal to choose a universal disk. This way you won't make mistakes.

High-quality cutting of stone is possible if there is diamond coating. The decisive factor in choice is the grain size of the abrasive. For a beautiful and high-quality cut, it should be smaller.However, to avoid engine overheating, it is still better to choose a size that is not the smallest.

The blade of such circles is vaguely similar to ordinary teeth. Their design looks like a monolithic canvas, divided at a certain distance. The shape is due to the fact that sawing is performed by friction of the abrasive on the hard surface of the stone.