Why does the chain fall off on an electric saw? DIY electric saw repair

Sometimes the chain from the saw can fly off while working. This is due to insufficient tension and lack of periodic checks. Repairing an electric chain saw is carried out independently; a few minutes are enough. After restoration, you need to check the tension - normally the movement should be smooth, and the chain should not sag. The article describes how to do this.

The content of the article

Main reasons

To carry out proper repair of an electric saw, you first need to understand why the chain falls off it. The main reasons are:

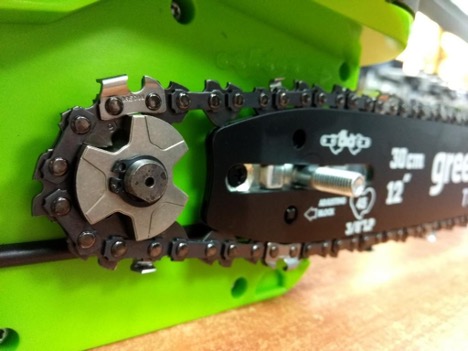

- tire breakdown (often deformation);

- the groove is badly worn;

- malfunction on the chain side (the internal teeth that slide along the groove have broken off).

First you need to make sure that the chain tension is normal. To do this, proceed as follows:

- Pull with fingers on either side.

- Inspect the internal teeth.

- They should slide normally along the groove and not come out of it completely.

- Manually pull the chain along the bar. If the move is smooth, there is no sagging, then everything is in order. This is how repairs to Makita electric saws and other models begin.

- If the chain is quite tight, there is a need for a little loosening, otherwise it may burst during sawing.

The main reason why a chain on an electric saw falls off is due to weak tension. This is noticeable by how much it sags.Moreover, if only 1-2 teeth (no more) fall out of the groove completely, this is an acceptable situation. But if there are 3 or more, tension must be applied (but not too tight).

How to carry out repairs

If the reason is due to weak tension, you need to tighten the chain a little. Moreover, it does not matter which circuit is on the yt4334 01 or other models. Their structure and principle of operation are the same. To troubleshoot the problem, proceed as follows:

- Loosen the nut that secures the tire.

- Using a screwdriver, turn the adjusting screw next to the tire.

- Then tighten the nut.

- Check the stroke - it should be smooth, not too tight, but without sagging.

- If necessary, adjust and check again.

There is also a problem in which the chain on the electric saw is not lubricated. The main reasons are related to clogging of the oil filter, tube or malfunction of the oil pump. In these cases, proceed as follows:

- Remove the protective cover.

- Remove the tire and chain.

- Clean all holes through which oil is supplied.

- Then you need to understand how to assemble the power saw. To do this, perform the same actions, but in reverse order.

It is not recommended to start work right away. First, it is better to make sure that the oil is no longer leaking, as it should only come out during operation. To do this, place a sheet of paper on the table and turn on the lamp. Then connect the saw to the outlet and run it over this sheet. If drops of oil appear on it, then the problem is solved.

Fault prevention

Repair of electric saws can be done at home. But to avoid problems, it is recommended to follow standard preventive measures:

- Clean and lubricate the filter regularly using technical oil.

- If necessary, it is better to replace the filter so that the saw works properly.

- Before starting work, check the bolts and nuts - they should be tightened sufficiently tightly.

- Lubricate bearings and sprocket regularly.

- Sharpen the chain on time. You can do this yourself using a file or contact a specialist who works with a professional tool.

Thus, the chain almost always falls off due to low tension. You can fix the problem yourself. However, do not pull it too tight - otherwise the chain may break.