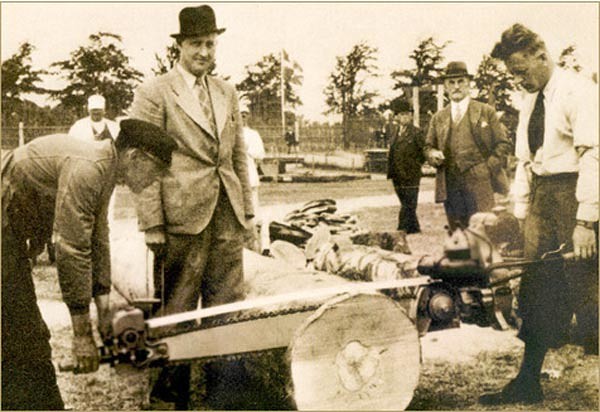

How to break in a chainsaw

After purchasing a chainsaw, it must be run-in. This will allow all parts of the equipment to get used to it. It is necessary to carry out the procedure correctly so as not to harm the device.

The content of the article

Why do you need a break-in?

The engine requires running-in, as it increases the adhesion between the interconnected elements of the tool. Even a slight play in the motor will cause problems in the future, such as jamming, scuffing, etc.

Therefore, before using it under heavy loads, it is necessary to test the tool, preparing it for further work.

Special fuel is used for break-in. About 20% more oil is added to it than with standard dressing.

Properly performed running-in allows the formation of suitable gaps in the area of the cylinder and piston rings. This will lead to increased power and compression of the device. Complete grinding in of elements will allow increase service life inventory.

It must be remembered that some modern models do not need this procedure. It is recommended to first study the equipment passport. It states the need for break-in.

Preparing a new chainsaw for first use

The first setup after purchasing the tool is to install the bar, chain and dog, if equipped.You should handle the chain carefully. It is necessary that its teeth are directed in the direction opposite to the drive. The chain tension should be checked; it should not be excessive. When all the parts are installed and checked, you can proceed to the next step.

Preparing the fuel mixture

To improve the quality of grinding of elements, you need to add a mixture with an increased concentration of oil in the composition. This is necessary due to the fact that during running-in the friction of the elements increases. An increased amount of oil will reduce the heating temperature.

AI-92 gasoline is suitable for running-in. It is recommended to use only high-quality fuel with declared ignition resistance. The oil should be two-stroke. The amount of each component for mixing is usually indicated in the instructions. Typically the ratio is 1 to 50 or 1 to 40.

It was noted that for this procedure, 20% more oil must be added. An additional 5-10 ml should be added to the standard value.

If running-in is carried out in winter, then the minimum increase in oil is 10 ml. In warm weather, 5 ml is enough.

During the cold period, the proportions are increased to eliminate the strong viscosity of the lubricant at low temperatures. Otherwise, the lubricant may be of poor quality.

It is recommended to use synthetic oil, despite the fact that it is more expensive than mineral oil. This substance better helps to increase the service life.

Refilling the oil pump

When the fuel is ready, you can start refueling. The composition can be stored for 2 weeks. The oil tank is on the same side as the fuel tank. The oil pump cover is located closer to the chain.To make sure that the lubricant has reached the chain, it is enough to lightly revoke the running unit. In this case, the lower part of the tire should be brought to the paper sheet. If an oil mark appears, it means the pump is working properly.

Setting up and starting the engine

This is the final stage before break-in. It is necessary to check that the chain brake is released. Even short-term operation of the tool with active locking will lead to rapid wear of the clutch.

If the equipment is equipped with an external fuel pump, it is recommended to press it several times. Before turning on the tool, place it on a flat surface. The ignition is turned on, but you need to press the handle from behind with your foot. The left hand holds the upper handle.

When the device is fixed, you should pull the starter lever, not too sharply, a couple of times. The engine will start and immediately turn off. This will happen due to a closed valve.

The preparatory stage is completed. All that remains is to open the valve, and again start the engine.

Features of work during running-in

Running in is carried out to additionally lubricate the parts, so there is no need to overload the tool. The load should be light. The device should not run idle for a long time - no more than a minute. A suitable pace is 3 minutes of operating at 60% capacity, then idling for a maximum of 20 seconds. The sawing material should not be too hard. At this stage it is better to work with birch or coniferous wood.

These steps allow you to perform a universal run-in. But if you plan to make the most accurate preparation, it is recommended to refer to the technical documentation.