When can an impact screwdriver come in handy and how to use it

Quite often, during plumbing or repair work, you have to deal with rusty bolts or other fasteners. Unfortunately, any attempt to use a regular screwdriver will not give the desired result and will not help unscrew the screws.

Moreover, in some cases you can tear off the spline, damage the tool, or get injured yourself. Particularly problems arise with aluminum fasteners, since corrosion acts almost like welding on such a connection (the elements stick one to the other). In such cases, a special tool comes to the rescue - an impact screwdriver.

The content of the article

How does an impact screwdriver work?

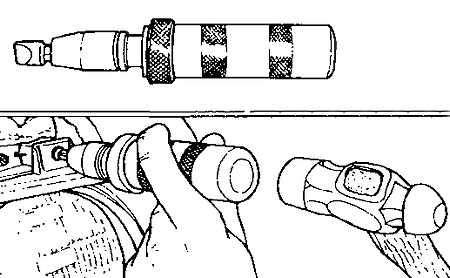

The impact screwdriver differs from the standard one in that it is equipped with a special reinforced housing. It is made of durable material and can withstand high shock loads. The set includes a huge set of bits - all sizes and types. They are installed on the rod in the same way as on a standard screwdriver with removable heads.

In addition to the reinforced body, such a tool has a torsion regulator. Many experts call such a screwdriver a reversible one. This instrument was extremely popular back in Soviet times.

True, then the design was monolithic and simpler.Over the years, the tool has been modified and equipped with a hexagon, which is fixed near the tip or near the handle.

With old screwdrivers, only two people can unscrew or tighten fasteners: one holds, the other strikes. A modern instrument is an improved device. Thanks to updates, the impact driver can now be used alone.

In the new models that are now being supplied to the market, the impact-rotating mechanism is located in the handle, and the tip is placed on the gear. Rotation begins when a heavy object strikes the handle.

Attention! The blows should not be struck with all your strength, but only with half force. Too much force may damage the handle and the rotating mechanism.

During impacts, the clip rotates, displacing the fasteners. It's enough. Then you can unscrew the screw using a regular screwdriver.

If you need to tighten the bolt, then almost the same operation is performed. It will have only one difference - the fastener is not screwed in all the way, because this can damage the element into which the fastener is screwed.

How to use an impact screwdriver

To make unscrewing work as fast and simple as possible, you just need to follow a few simple rules and avoid mistakes. These rules include:

- The fastener must be prepared for unscrewing. Before striking it, you need to apply WD-40. It will clean off the rust. You can also use kerosene or brake fluid. After this, the fasteners are wiped with a cloth.

- At the next stage, the tip must be fixed into the slot perpendicular to the location of the fastener head.

- Strike the end of the tool handle with a metal object. Remember that you need to hit with medium force.

- The blows must be repeated until the head of the fastener moves slightly to the side. After each blow, check the screw movement.

- Complete unscrewing of the screw using a standard screwdriver.

It is recommended that after the head of the fastener has moved at least a little to the side, put it in reverse and apply several blows again. After this, put the screwdriver back on to unscrew and make a few blows. You need to repeat this cycle 3-4 times. This allows you to unscrew the fastener much easier and faster, and also maintain its integrity.

If the fastener still does not give way, you need to apply a small amount of WD-40 and leave for half an hour. Then repeat the unscrewing manipulations.

If there is a reverse function, then such a screwdriver can also be used to tighten fasteners. To do this, also repeat the blows several times, however, as mentioned above, avoid completely twisting.

This tool has a number of advantages. These include:

- efficient use of impact energy;

- a small force is enough to unscrew a screw or other fastener;

- possibility of unscrewing rusty connections.

However, it is worth considering some disadvantages. These include the risk of breaking the impact-rotating mechanism and its wear.

Safety precautions at work

To avoid various troubles during work, you must follow safety precautions:

- First of all, put on thick work gloves on your hands. They will completely prevent the handle from slipping when striking it.

- When striking, you don't need to use too much force. Also, don't use a hammer that's too big. You can get by with a standard one, the weight of which does not exceed 500 grams.

- The hammer must be held straight while unscrewing. Any deviation to the side is prohibited, since the striker may slip off the screwdriver. This can lead to various problems: hand injury, tool breakage, etc.