Types of screwdrivers

Any thrifty owner or housewife will always have a certain basic set of universal tools in their home, which will most often include a hammer, pliers and a pair of screwdrivers. And if everything is most often clear with the first two items, then choosing a high-quality and truly universal screwdriver is not so easy. The modern market offers the consumer a huge number of varieties of this instrument, which makes the choice even more difficult. In this article we will analyze in detail the most common types of screwdrivers and talk about the features of each of them.

The content of the article

Tool classification

Classic screwdriver consists of a handle made of various materials (from plastic and wood to steel and dielectrics), a rod and a tip, which is sometimes called a slot. Depending on the type, materials and shape of these three main elements, screwdrivers differ from each other.

The most popular and widely used both in everyday life and in professional activities include locksmith screwdrivers - flat and cross. Thanks to the straight or cross-shaped slot, such a tool is convenient for unscrewing common types of fasteners (screws, self-tapping screws, etc.).

Reference. Using a standard Phillips-head screwdriver, it is unlikely that you will be able to unscrew fasteners with a straight slot, but if the fastener’s slot is cross-shaped and the tip of the screwdriver is straight, then such a screw can still be unscrewed.

Very popular in everyday life and the so-called adjustable screwdriver. Its rod can be easily removed from the handle by hand, and there are different types of slots at different ends of the rod, which makes this tool much more versatile. Some adjustable models can have 4 tips in a set at once, which further expands their functions, and many even have a whole set of interchangeable bits for any slots.

Precision screwdriver useful for those who often work with small parts and mechanisms. Very often, such a tool can be seen in the hands of mobile equipment repairers (smartphones, tablets, etc.).

Two-piece models got their name for the use of polypropylene and rubber in the manufacture of the handle. Such products usually have excellent ergonomic qualities. The material from which the handle is made does not slip even in wet hands, and the magnetic coating on the tip is designed to prevent screws from falling out and getting lost.

Watchmakers usually use special clock screwdrivers. Their main difference is thin (no more than 1 mm) tips. You often have to work with them under a magnifying glass. Most often, such products are sold in sets, but you can also find individual copies for a specific slot size.

Continuing to talk about professional tools, we cannot fail to mention the so-called modernized types of screwdrivers, most often used by specialists in a particular profession. Some of the representatives of this type are dielectric models designed to work with electrical networks. During operation, such a tool protects the electrician from electric shock, even if the network is energized.

Reference. Dielectric models are often equipped with a test indicator. With its help, you can determine the approximate location of wiring hidden in the surface of the walls, and sometimes the voltage level in it.

With help impact screwdrivers you can “drown” the screw into the coating without applying additional force from the outside: their design allows you to create an enhanced impulse directed to the slot. With the help of such a screwdriver it is very convenient to unscrew rusted fasteners.

They are considered quite convenient for long-term use (but expensive) reversible screwdrivers. They are equipped with a so-called ratchet mechanism, which allows using this tool to install and dismantle fasteners without taking your hand off the handle, simply by making return movements with your hand.

The principle of operation of such a mechanism is reminiscent of ratchets, which are often used by auto mechanics to loosen bolts. Most often, reversible models have several replaceable bits for different types of fastenings.

Cordless screwdrivers According to the principle of operation and appearance, they are more reminiscent of screwdrivers, but they are still placed in a separate category. Adjusting the screwing force transmitted to the rod allows the master to “even out” the force that all fixed structural elements will exert on its frame. Very often, such models are used in the assembly of furniture and other structural products.

Deserves special attention telescopic models, in which the length of the rod is adjustable. With this tool you can unscrew fasteners even in hard-to-reach places.

Very often in work it happens that there is no way to get to the desired screw at a right angle, no matter what the length of the rod, and then they come to the rescue screwdrivers with flexible shaft. Their rod is made of bendable material and can change the bending angle to certain values, allowing you to unscrew even the most “difficult” self-tapping screw or screw.

Screwdriver markings

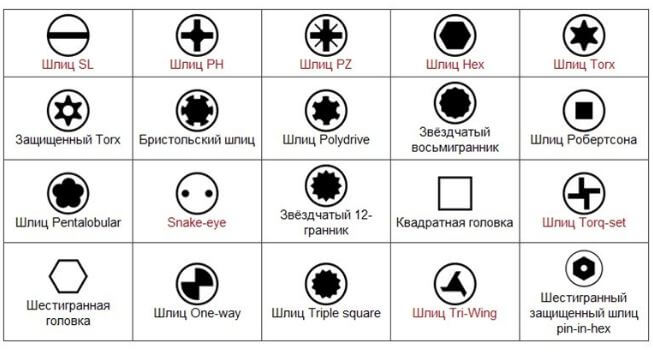

On many screwdrivers you can find alphanumeric designations that determine the purpose of the tool. In order to fully understand the main types of screwdriver markings, we suggest that you familiarize yourself with this table indicating the types of tips.

Products are also marked depending on the diameter and length of the rod: from 0 to 4 with a minimum diameter of 4 mm (for number 0) and a maximum of 10 mm (for number 4). At the same time, “zeros” are better suited for screws with an external thread diameter of less than 2 mm, while “fours” will cope better with fasteners with an external thread diameter of 7 mm or more.

In addition, the marking may contain information about the material used to make the rod. One of the most popular materials for screwdriver blades today is chromium vanadium.

there is everything to work at one hundred percent