How to demagnetize a screwdriver

Sometimes the magnetization of a screwdriver is beneficial, and sometimes it is an undesirable property. For example, when metal shavings are present at a work site, it is better for them to remain there rather than stick to the tool. Is it possible to demagnetize a screwdriver and how to do it?

The content of the article

Why does metal become magnetized?

I will not go into quantum mechanics and will try to explain it in the simplest possible terms. The magnets we are all familiar with are products made entirely from a so-called ferromagnet, which creates its own magnetic field.

Elements such as iron, cobalt and nickel that make up a screwdriver are also ferromagnetic.

Reference. Since the alloy also contains other substances, this instrument cannot be called a magnet in the usual sense.

However, under certain conditions, the magnetic field generated by ferromagnets can increase or decrease.

Strengthening of this field, or, in other words, magnetization of the screwdriver, usually occurs when working close to electric motors, magnetrons and other elements. The metal, as it were, “takes away” the properties of the field surrounding it.

How to demagnetize using the device

It is impossible to completely remove the magnetic properties of a metal product. You can only reduce its magnetism to such an extent that chips and small parts do not stick.This is important to consider when repairing electronics.

For such a decrease (or, conversely, an increase, if necessary), there are special demagnetizers, which can be purchased at repair stores or companies selling tools. They are inexpensive and look something like this:

As you can see, everything is simple: two spaces, the upper one demagnetizes, the lower one, on the contrary, magnetizes. The tool is placed into the desired area and held there for about ten seconds, after which it is ready for use.

Reference. A screwdriver is usually magnetized faster than it is demagnetized.

There are different sized models of such devices: from pocket-sized ones - for small tools, to huge ones - for use in industrial conditions. Accordingly, they differ in the power of impact.

What makes such a pocket-sized device convenient is that it does not require connection to anything - it is always ready to use. It’s easy to check its effect even in a store: you just need to take a screwdriver and some small part, for example, a nut, and conduct an experiment. After magnetizing the screwdriver, the nut should be easily attracted to it, and after demagnetization it should not “stick” even with close contact.

What other ways are there?

If you have a round magnet with a hole in the middle in your house, you can use it to demagnetize a screwdriver.

Important! The hole should be wide enough so that the entire tool and handle can fit through it.

To do this, simply thread the screwdriver through the magnet, starting from the tip and ending with the bottom of the handle. This action is performed at a leisurely pace. As a rule, one time is enough to demagnetize, but you can repeat it if necessary.

If there is no hole or it is not wide enough, there is a second method. Position the screwdriver in relation to the magnet at the minimum distance at which it is not attracted to it. Then, making small “oscillatory” movements, move it from one pole to the other, gradually moving away from the center. The further away it is, the less vibration should be. After this it should demagnetize.

For the third method we will need a magnetometer. First, determine the level of magnetic field strength of the screwdriver. Then find a field with the same voltage on the magnet, but at a pole with the opposite sign. After that, all you have to do is press the screwdriver exactly to this part.

We create a device for demagnetization with our own hands

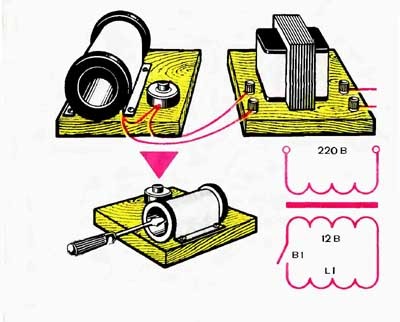

To do this, you will need a spool of wire that can withstand 120-127 volts and a powerful step-down transformer. The structure is assembled according to the following scheme.

Wind the wire around the coil of the transformer and connect it to it. After this, a screwdriver is placed in the internal cavity of this coil and alternating voltage is applied.

Reference. For reverse action (magnetizing the tool), the voltage changes to constant.

If you have an old unnecessary TV, you can assemble a device with your own hands, which includes a kinescope demagnetization loop (it is located around it). Connect its ends together to form a circle and wrap it with electrical tape, leaving two wires outside.

Attach the resulting structure to a block of wood, which will serve as a handle. Using a button from any power tool, connect two wires to a 220 volt network.

Important! Be sure to insulate all wires and contacts to prevent electric shock!

The device is ready for use. Turn it on and place a screwdriver in the ring. Hold it for no longer than 5 seconds, then turn off the device, otherwise it may overheat.

There are a huge number of ways to demagnetize a screwdriver at home, so you can choose any one you want.