What is an impact screwdriver

During plumbing work, a craftsman may often encounter a problem in the form of rusted fasteners. You can try to unscrew it with a regular screwdriver or apply WD-40 to it to remove the rust. But this may not always work out.

The splines can be torn off, the rust will not dissolve, or the tool will simply deteriorate. It is especially difficult to remove steel bolts from a metal base. Rust is a very strong “connector”, which makes it very difficult to unscrew the fasteners.

However, there is one tool that can handle such bolts without any problems. This is an impact screwdriver. With it, even the biggest problem turns into a small obstacle that anyone can cope with.

The content of the article

Impact screwdriver: what does it mean, principle of operation

An impact screwdriver differs from a regular screwdriver in that it has a large and reinforced body made of high-strength metal. The package includes a set of bits: flat and Phillips. They are installed in the same way as on a regular screwdriver.

The impact screwdriver is equipped with a special device - a torque regulator, which is why it is sometimes called reversible. This instrument was popular back in Soviet times. True, in those years it had a simpler design with the presence of a monolithic core.

After some time, the tool underwent a slight modification, and it began to be equipped with a hexagon, which is installed near the tip. On some models it may be mounted on the handle. Therefore, such screwdrivers are capable of transmitting rotational force from the key.

Older models could only be used by two people: one master strikes the handle, and the second rotates the fastener. The modern product is a modified device that can handle any bolts. It is convenient to work with him alone.

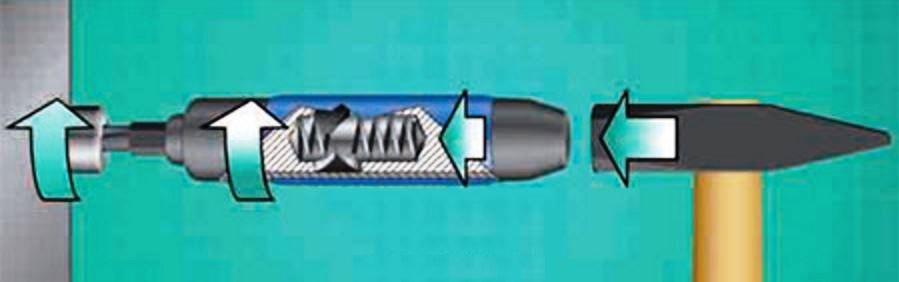

In current modifications, the impact-rotating mechanism is placed in the handle, and the sting is mounted on the gear. Rotation begins when the impact force of a heavy object (most often a hammer) begins to act on the handle.

The clip begins to move around the axis, due to which the fastener moves by several degrees. This is enough for the connection to loosen and the bolt to be unscrewed. The mechanism returns to its original position due to special springs.

If you need to tighten the bolt, then you should do the same operation, but only in reverse order, i.e. tighten the fastener with a regular screwdriver, but not all the way, then install the impact tool and use a hammer to tighten the bolt or screw until it stops.

Attention! If you want to fix the fastener using an impact tool, then never screw it all the way with a regular screwdriver. If you do this, the impact may damage the housing or the surface of the work area where the screw is screwed.

Tool characteristics

If you want to buy an impact screwdriver, then you need to understand some of the nuances and key technical characteristics of the tool, as well as the configuration of specific models.

Reference. First of all, pay attention to the metal from which it is made. Trusted companies never use poor quality steel. But products from China can sometimes be made from low-grade metal. Therefore, avoid fakes, since at the first blow the instrument may either become deformed or simply crumble in your hands.

The next thing you should pay attention to when purchasing this instrument is the presence of reverse. It greatly expands the basic capabilities of a screwdriver, allowing you to both twist and tighten fasteners.

The next important aspect is the design of the handle. It is designed to hold the tool and strike it. If it has a special pad (it can be made of rubber, polyurethane or polyethylene), then it will be much easier to hold the screwdriver during impacts. If the lining has a “tide”, this will increase safety during operation.

Most often, the dimensions of the handle may differ from each other, and there are several important nuances here:

- if the handle is of a standard size, then it has high strength, but it cannot be used in cramped conditions;

- if the handle is slightly smaller than the standard size, then it can work in extreme conditions and in limited space - however, in this case the reliability of the tool suffers.

When choosing an impact driver, weigh the pros and cons, and only then make a purchase.

Modern impact screwdrivers are equipped with a set of different attachments, without which this tool becomes simply ineffective. Included are:

- cartridge holder;

- universal nozzles.

The set is replete with attachments for different splines and hexagons. When purchasing these elements, always pay attention to their quality, since this is an important nuance that determines the reliability of the tool and its service life.

Advantages and disadvantages of the tool

All tools have their advantages and disadvantages, and an impact driver is no exception to this rule. The advantages include:

- the ability to unscrew rusty fasteners when a conventional screwdriver cannot do the job;

- effective distribution of impact energy;

- the ability to work alone without the involvement of a partner.

If we talk about the minuses, then there are practically none. True, during work you need to follow the rules to protect both yourself and the tool. Therefore, the disadvantages include:

- Possibility of damage to the impact-rotating unit. The paradox here is that old monolithic structures have a longer service life than modern modernized solutions. To avoid damage, it is enough not to hit the impact-rotating mechanism too hard.

- Tendency to wear out quickly. Gear teeth are subject to friction, which is accompanied by shock loads. With prolonged use, their resource begins to decline rapidly.

How to use

To make the work process as simple as possible, do not make mistakes and follow the basic rules of work:

- Pre-clean the fasteners from rust with a rag - you can apply WD-40 or kerosene for 5 minutes;

- fix the tip with a pin, placing it strictly perpendicular to the head of the fastener;

- strike the end of the handle with a heavy object with medium force;

- repeat the blows until the screw or its head moves a few degrees to the side;

- Complete the unscrewing process with a regular screwdriver.

If the impact screwdriver has a reverse, then you can set it to tightening mode, apply a few blows and then set it to unscrewing again. This way you remove rust elements from the spiral of the fastener.

Also, do not forget about safety precautions. Protect your hands with gloves or overalls that not only cover your hands, but can also prevent the handle from slipping. Don't put in too much effort. The weight of the hammer can be no more than 50 grams. Strike with medium force. Hold the hammer straight, without tilting it to the side.