How and with what to brew a titanium shovel at home

A shovel is an indispensable piece of equipment in the arsenal of any land owner. Titanium models are highly durable and have other important advantages. However, sometimes with increased load on the bayonet the metal may burst. Let's figure out how to brew shovel made of titanium and what to consider in the process.

The content of the article

Features of titanium welding

The weldability of this metal is influenced by several factors. First of all, titanium has a high chemical reaction towards gases in the air, including nitrogen, oxygen and hydrogen. It is also important that the metal has a greater tendency to grain growth when the temperature exceeds 800 degrees.

If titanium is heated to 350 degrees, it begins to actively absorb oxygen. As a result, a film is formed on the surface (in the welding area), the color of which varies from yellow to purple, gradually turning into white.

Heating to 500 degrees leads to an increase in the strength and hardness of the metal. However, its plastic properties decrease.

The interaction of titanium and hydrogen leads to a harmful phenomenon - hydrogen embrittlement. It contributes to increased fragility of the material. After the titanium cools down, the welded part falls off after some time.

An increase in the amount of grain due to exposure to high temperatures reduces the strength of the metal. It is worth remembering that titanium has a high melting point. When working with it, you must use a very powerful concentrated heat source.

When welding, the seam must be protected on both sides. Particular attention is paid to edge preparation. You don't need to warm it up for a long time. When welding a titanium shovel, it is necessary to carefully monitor the temperature conditions. To protect the metal in the work area, it is recommended to use special flux compounds. Metal trims will also work. Gas cushions can be used. To create them, packed chambers are used.

In the process of correcting defects on a shovel, you must carefully observe safety precautions. You should work extremely carefully.

Necessary materials and equipment for welding a titanium shovel

The process will require:

- Welding machine. It must support TIG mode. It must have a burner.

- A cylinder filled with protective gas. Helium, argon or a mixture of both are suitable.

- Tungsten electrodes that do not melt.

- Filler wire.

Preparing for welding at home

To prepare the metal for welding, it is necessary to process the edges of the areas where the process will be carried out. Be sure to remove the metal layer with a high content of oxygen and nitrogen. The presence of these particles in the work area will lead to a deterioration in the properties of the formed seam. The fragility of the metal will increase.

If the workpieces have a thickness of no more than 4 mm, you can do without cutting the edges during welding. In other cases, it is performed while maintaining an opening angle of 60 degrees.

It is also necessary to protect the root of the seam and the working area on the reverse side. Even if the treatment does not reach the opposite side. Indeed, when titanium interacts with gases from the surrounding air, the reaction begins as soon as the temperature reaches 300 degrees.

To protect the seam on the reverse side, pads made of steel or copper are used. They need to be fitted tightly. You can also use argon blowing, directed into special grooves or inside the structure.

If the process can be carried out without protecting the inside of the seams, then breaks must be taken to allow the surface to cool. The seams themselves should be short, no more than 20 mm.

Method of welding a titanium shovel with a non-consumable electrode (TIG method)

TIG is a welding technology that uses a tungsten-based electrode under the protection of inert gases. Its core is considered non-melting. This is manual arc welding - an arc is formed between the electrode and the workpiece, and shielding gas comes from the torch. Additives are supplied manually. The electrode is sharpened at an angle of 45 degrees. The current must be maintained within 100 amperes.

Products up to 1.5 mm thick can be butt-joined without the use of additives. In other cases, the rod is fed. The additive must have a composition suitable for the alloy of the work area. Before starting the process, it must be annealed in a vacuum. This will remove the hydrogen. When sealed, the additive will retain its properties for a maximum of 5 days.

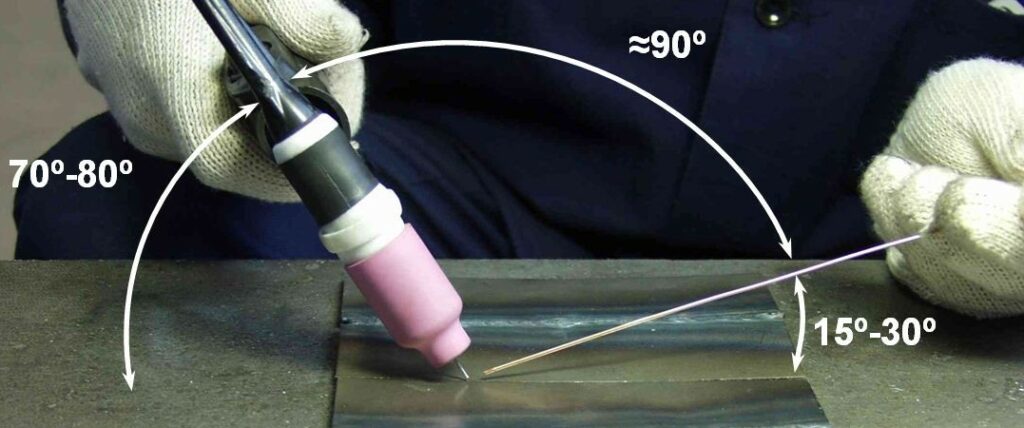

To perform the work, a current of constant polarity is required, the voltage of which reaches 15V. The electrode must be directed to the surface at a certain angle - 70–80°. The additive is supplied perpendicular to the electrode axis.

The photo below shows the location of the electrode and additive when TIG welding any titanium product.

The formation of the seam must be carried out with precise movements. Until the work area has completely cooled down, it is recommended to blow argon onto the seam. The process must be performed extremely carefully.

I broke 2 pieces. These are bad shovels, don't trust anyone. They are like toys. And if the soil is very light, then they dig there with a pitchfork.