How to sharpen an ax

An ax is one of the main tools in the household, and in a private house with a large plot it is completely irreplaceable. Its sharp and right a sharpened blade will make the work much easier and faster, and a blunt tool, on the contrary, will reduce labor productivity and may even harm the owner. To prepare, you will need a grinder, a sharpening machine, emery or a file. Let's figure out how to do this competently and safely.

The content of the article

How to properly sharpen an ax at home

Maintaining an ax in proper condition is not easy. However, it is possible to independently prepare it for work using a standard set of tools. Before going to the workshop, try to do everything yourself.

Theoretical knowledge and technical equipment are the key to a successful event.

Sharpening angle options

To define parameters the purpose of the ax should be determined. There are several standard values:

- 40–60 degrees – forest cutting;

- 30–35 – universal;

- 20–25 – for finishing work;

- 15–20 – highly specialized.

The angle directly affects the sharpness of the blade and depends on several parameters. In particular, the nature of the application, the quality of the metal, the type of wood and its moisture content. The main thing to remember is that a tool with a sharp angle has to be sharpened more often.

Chamfer width

This parameter affects the durability and degree of sharpness of the tool.The standard indicator is 1–2 millimeters. Depends on, how the ax will fit into the tree and how much effort it will take to extract it. At the same time, there is metal of poor quality. In this case, the chamfer is made on both sides at different angles - 15 and 20 degrees.

Do-it-yourself ax sharpening: methods

There are different sharpening methods: using hand or power tools. Moreover, in both of them it is important to protect the body and, most importantly, the face and eyes from damage. Better before you start prepare a template the required angle - this will significantly facilitate further actions. It can be cut from tin using metal scissors.

On the grinding machine

The simplest and most effective way. Using an electric sharpener, the blade is given the desired shape. At the same time, the quality is higher than with manual sharpening. At the beginning paint over the required treatment area with a marker. Further according to the scheme:

- The ax is fixed on the machine at the desired angle with the blade as the abrasive wheel rotates.

- Initially, the circle is turned by hand to check the marker: it should be completely erased from the surface of the blade.

- When the planned result is achieved, uniform sharpening occurs on both sides.

- Next, the ax is brought at 45 degrees to the circle and a chamfer is made.

- Finally, the blade is trimmed with a sharpener.

It is important to ensure that the metal does not overheat. It is better to prepare cold water for cooling.

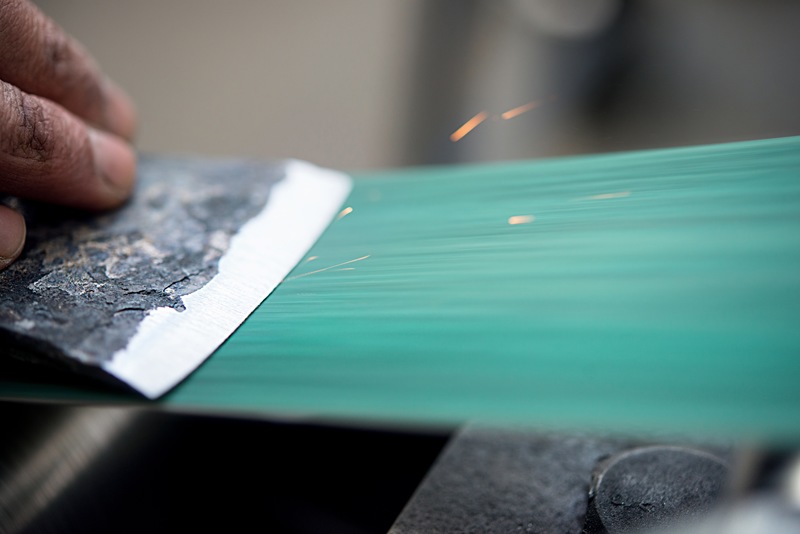

Bulgarian

This method is considered the most dangerous. Masters do not advise using it without sufficient experience with the tool. In addition to the fact that the metal overheats greatly and loses strength, the angle may be uneven. But if you have certain skills, you can sharpen an ax in this way.

Step by step guide:

- Buy a special disc.

- Install it on the grinder, remove the casing from it.

- Secure the tool in a vice.

The angle will be controlled independently. It is very important to strictly follow all safety measures.

Sandpaper

To do this, you will need three types of paper - coarse, medium and fine-grained. The blade of the tool is first cleaned of dirt with a wire brush. The sharpening process is similar to kitchen knives: the material is spread on a flat surface, after which the blade is moved along it in semicircular movements evenly on both sides when the required angle is reached. The method is quite simple, but the longest.

Bruskom

To do this, place the ax so that its blade hangs over the table, press the head to the surface and use a sharpener to bring the tool to the desired sharpness. As soon as a metal burr appears on one edge, it is turned over to the other side. The block itself is moistened with water.

File

Method similar to the previous one. The blade is cleaned, the ax is fixed and manipulations are performed. In this case, the file does not need to be moistened with water.

In general, when preparing a tool manually, it is best to combine several options. In this case, the method itself will look like this:

- Cleaning the ax blade with a wire brush and sandpaper.

- File processing along the width of the chamfer.

- Using a fine-grained moistened stone, bring it to the required angle.

At the very end, it is better to lubricate the blade with a special paste to protect it from rust.

The ax is sharpened by hand, but much easier - using a power tool. In this case, the quality of sharpening will be better than in the workshop. Master adjusts the angle to suit your own needs. But the most important thing is the pleasure of working with a sharp tool sharpened with your own hands.

Ax sharpening angle “40–60 degrees – forest cutting”? You'll get tired of even chopping wood!

It is convenient to sharpen an ax with a grinder with RO - you just need to put on a fine-grained cleaning blade, which will not spoil the lens sharpening.