How to insert a mixer into a drill? Selecting and installing a suitable nozzle

Instructions on how to insert the mixer into the drill depend on the type of chuck. In some cases you will need a key, in others the nozzle is secured manually. Moreover, when purchasing a device, you need to make sure that it exactly matches the connector. You should also pay attention to other parameters described in this material.

The content of the article

Chuck device

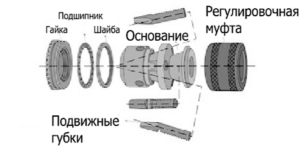

To properly understand how to insert a mixer attachment, you need to understand how the cartridge is designed on a specific model. You should also familiarize yourself with their types. The jaw chuck consists of a base, movable jaws and an adjusting sleeve. The elements are screwed with a nut through a bearing with a washer, as shown in the diagram.

There are 2 types of jaw chucks:

- Quick-clamping.

- Key.

In the latter case, a key is required for installation. It is inserted into the hole and scrolled clockwise. Thanks to this, the mixer, like any other attachment, is securely fixed in the desired position.

As for the quick-clamping mechanism, it is further divided into 2 types:

- single-coupler;

- double coupling

As the name suggests, they consist of 1 or 2 couplings respectively. In the first case, you just need to hold the cartridge with one hand. Replacement is carried out quickly and without keys, but the nozzle is not fixed as tightly as in the key assembly.

In the second case, you also need to clamp one coupling. The other hand turns the other.Thanks to this, installation is very simple and takes just seconds. In all cases, the mixer is mounted strictly vertically - otherwise, during operation, both the nozzle and the device itself can be damaged.

Step-by-step installation instructions

The installation process itself is quite simple - you need to do this:

- Make sure that the device is unplugged from the outlet.

- Examine the cartridge, understand how it works.

- In the case of a key type, insert the key and turn clockwise.

- If the chuck is a quick-release chuck, replace it manually.

- After installation, check how securely the mixer is and whether there are any vibrations.

- Test the work.

Mixer selection criteria

Another important question relates to which attachment to choose for your drill mixer. On the one hand, this is not difficult, but in practice certain difficulties may arise. To avoid them, you should study the technical specifications. One of the main ones is the type of shank, it can be:

- cylindrical;

- SDS+;

- 6-sided;

- M14.

To make the right choice, you need to look at what connector the drill is equipped with. Typically a cylindrical type shank is used, sometimes 6-sided. Other types are suitable for rotary hammers. If you are not sure, you can simply take the tool with you and decide on the spot.

Other characteristics should also be taken into account:

- basket parameters (diameter, height) - they should be maximum if a large batch volume is planned;

- nozzle length – in the range of 40-60 cm, selected depending on the height of the container;

- value for money – preference should be given to branded products; this is especially important if batches are planned to be carried out frequently.

Thus, purchasing and installing a nozzle is not so difficult. The main condition is to take into account the type and dimensions of the whisk.Mount it with or without a key (for a quick-release chuck).