How to create a router from a grinder with your own hands? Step-by-step instruction

Fraser – a useful tool for curly woodworking. It is not always cheap, so there is a need to make the device yourself using available materials and tools. One option is to make a router from a grinder. This is a completely convenient and reliable installation that can be used for various tasks. This article explains step by step how to design it correctly.

The content of the article

Tools and materials

To make a homemade device, you will need a fairly powerful grinder or angle grinder. It is clear that it must be fully operational, without defects. It is also necessary to prepare other tools and available materials:

- a welding machine (it will be useful only if the milling cutter from an angle grinder is made from metal elements with your own hands);

- electric drill;

- set of drills;

- a set of screwdrivers or a screwdriver;

- fasteners;

- construction level;

- construction tape;

- sheets of plywood or chipboard (thickness should be 10 mm or more);

- alternative option - metal sheets with a thickness of 3 mm;

- set of wrenches;

- square;

- saw for working on wood or metal;

- metal corners (instead you can use a wooden beam with a cross section of 50*50 mm);

- punch;

- hex keys;

- file, sandpaper.

Types of milling cutters

Before you start constructing a wood milling cutter from an angle grinder with your own hands, you need to decide which type of tool is best suited. There are 2 design options:

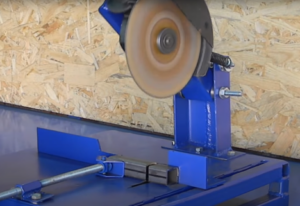

- Stationary milling machine from a grinder.

- Mobile device.

The stationary one is a full-fledged wooden table with an installation, that is, a workbench. It can be used to work with both wooden and metal workpieces. But in the latter case, the power of the device must reach at least 1100 W.

Such a device consists of 3 elements:

- Base.

- Tabletop with slats.

- Drive unit.

This is a quite convenient design, but it is not mobile. Therefore, in practice, a manual milling cutter made from a grinder is most often used. This is a homemade installation that can be completed in just a few hours.

To understand how to make a milling cutter from an angle grinder for different tasks, you need to consider several points before assembly:

- The guide rails must be removable, because the blanks come in different shapes.

- It is better to fix them with self-tapping screws. Moreover, the caps of the fastening elements must go completely into the thickness so as not to interfere with the surface.

- In order for a homemade grinder mill to perform as many tasks as possible, you need to purchase additional key bits and cutting discs. They are conveniently fixed on the shaft using a clamping nut, as well as an adapter.

Step-by-step instruction

You can make a milling machine from a grinder with your own hands according to the following instructions:

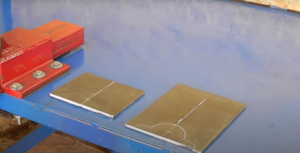

- Mark a design on a metal or wooden sheet as shown in the photo.

- Secure the workpiece in the frame and cut off the excess parts along the contour.

- The resulting detail is the sole of the future device. This is the first stage of instructions on how to make a wood router from a grinder.

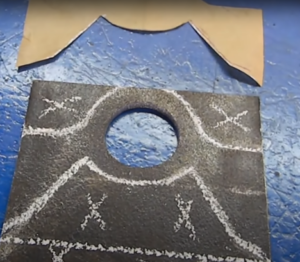

- Using a metal saw and a hammer drill, make a round hole in another sheet of metal.

- The result is a blank for a milling cutter made from an angle grinder.

- Make another part according to this pattern.

- A new blank is obtained. Thanks to these elements, the router attachment for the grinder will allow you to obtain parts of the correct shape.

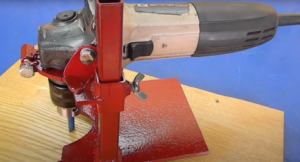

- Try it on the grinder to understand where you need to grind the future clamp.

- Make 2 pieces of metal profile 20*20 mm and 25*25 mm.

- Assemble the structure as shown in the photo and weld the components.

- Make a cut on the ring.

- Drill out the thread to allow the bolt to move freely. Thanks to this, the wood milling cutter will work correctly.

- Screw it in.

- Knock the metal loop at a right angle.

- Place it on the grinder on both sides and secure with bolts.

- You will get something like this. It will ensure the reliability of the design, regardless of which attachment to the grinder and wood router will be used.

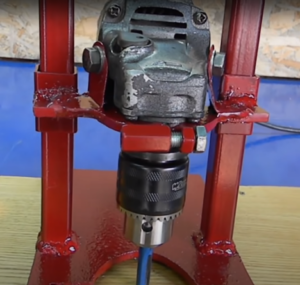

- Screw the chuck spindle onto the tool.

- Assemble the structure and tighten the bolts.

- Install a lamella milling cutter from an angle grinder onto the support with your own hands.

- The result is such a setup - now you can start testing it.

- Turn on the engine and carefully walk along the wooden workpiece.

- A do-it-yourself grinder cutter works quite well. But in practice, sometimes you have to make an adapter from a stud and an extended nut. This device provides excellent contact with the working surface of the wood.

Basic rules of work

A lamella milling cutter made from an angle grinder is subject to all the basic rules that apply to professional devices:

- Before processing, you need to understand the characteristics of the material and select the appropriate nozzle.

- It is unacceptable to remove the protective housing.

- Always start at minimum speed.

- It is better not to use a large grinder - it requires a lot of force, and such a tool can simply break out of your hands.

- Even with “harmless” parts you should wear gloves.

- You can only work in one plane.

- A manual milling cutter made from an angle grinder with your own hands is a safe tool if you follow the described rules. Another requirement is to disconnect the power before replacing the disc or attachment.

- Before you start using a grinder, first check the uniformity of the wooden surface and thickness so that there are no metal parts in it

Thus, a homemade wood router from an angle grinder can be made by one person within a day. For this, the necessary tools and materials are first prepared. The work is carried out strictly according to the drawing so that all the parts correspond exactly to each other. It is advisable to test the assembled installation on different materials, after which you can begin the main work.