How to work with a hammer drill? Design and operating modes of a hammer drill

There are several ways to work with a hammer drill. The tool operates in several modes, the main ones being drilling, chiselling and drilling. For proper operation, you need to adjust the switch and hold the device firmly. The main features of use are described in detail in this material.

The content of the article

Tool structure

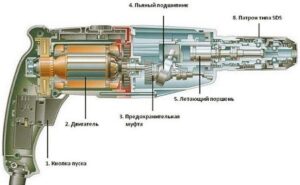

To understand the hammer drill and how to use it, you should familiarize yourself with the structure of this tool. This is a mechanism powered by an electric motor. It consists of 5 main components, indicated in the diagram.

The main element is the electric motor. When the chain starts, it begins to rotate quickly, causing the attachments to rotate and simultaneously make impact movements. The main parts of the engine are the rotor and the stator mechanism. Each of them has several windings that create electromagnetic fields.

The coils are brought out to the armature contacts. Due to the fact that the windings switch, force fields are created that rotate the rotor. All hammer drill modes work on this principle.

Another element is the safety clutch. It is necessary to stop the rotation of the chuck in case of jamming of the working attachment.The coupling is mounted on each device, otherwise the tool will be “twisted” out of your hands, which can lead to injury.

The next component is the impact mechanism. It provides all the ways to use a hammer drill on concrete and other surfaces. In practice, 2 types of mechanisms are used:

- pneumatic;

- mechanical.

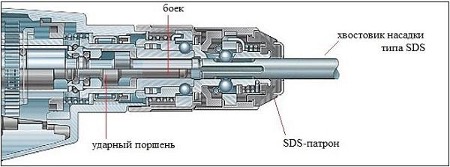

The first option is most often used. When the main shaft rotates, the “drunk” (also called swinging) bearing moves translationally and transmits impulse to the ram, which is part of the cylinder. It contains compressed air, which pushes the piston. In this case, the firing pin hits the working part of the cartridge. And the drill, fixed in the chuck, hits directly on concrete or other surface.

The device of a Makita hammer drill or other models must include a cartridge. It can be of 2 types of SDS – plus and max. In the first case, the shank is clamped using 2 locking balls.

In the second case, tools with shanks of other types are fixed in the chucks.

Operating modes

There are different ways to work with a hammer drill. The tool operates in 3 main modes. Some models also have additional options described in the following sections.

Drilling

To work in this mode, you need to install the switch in the place marked “drill”. The device is used for drilling to form holes in wood, metal and other objects. Essentially, it works in a similar way to a drill. You need to install the drill in the right place and get to work.

Hammer drilling (drilling)

Some materials, such as brick, reinforced concrete and concrete, are particularly dense. Therefore, drilling them is very difficult.To understand how to use a hammer drill correctly in this case, you should use the hammer drilling mode.

To do this, the switch is placed opposite the designation of the drill and hammer. The tool rotates and simultaneously performs translational movements. This is a special operating mode that involves the use of special drills made of carbide materials. They even destroy reinforced concrete structures and at the same time ensure safety for the operator.

Chiseling

The rotary hammer operating modes allow you to perform different tasks. For example, if you need to hammer concrete, you should move the switch to the hammer position. Then the mechanism does not rotate, but moves exclusively back and forth. To do this, you need to use a spatula, chisel or peak. When working in impact mode, it is necessary to hold the tool very tightly, since significant force is required.

Reverse

To understand how to operate a hammer drill correctly, you also need to master the reverse mode. This is a reverse stroke, which is needed in cases where the drill is stuck in the surface. All tools are equipped with this function, but the technical solutions are different.

In inexpensive models for household use, electric reverse is used. In professional devices, a gearbox with mechanical gear shifting is often installed.

Other modes

Additional options can be installed on expensive rotary hammers. For example, there are models with a chisel rotation. Thanks to this, after each blow the bit is rotated by one degree or another. The tool is less likely to get stuck in concrete, making the job easier.

Regardless of the selected mode, you should carefully study how to hammer a wall with a hammer drill.The tool is powerful and requires compliance with safety precautions. Therefore, the operator must wear a mask and goggles. If the hole is too long, you should start with small drills, working gradually. Before you begin, it is recommended that you carefully inspect the tool to ensure that it is in working order and complete.