What kind of wood is an ax handle made from?

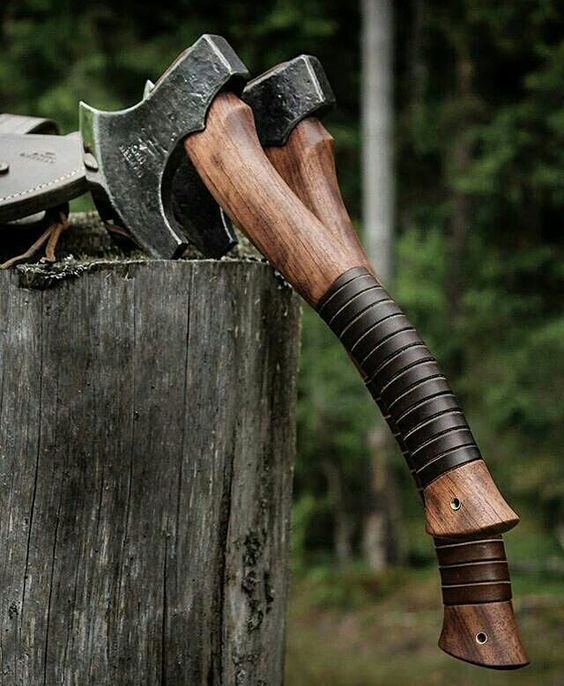

Carpenters, builders, and summer residents always have an ax in stock. It is used when cutting down trees and chopping firewood. The handle of the tool is called the ax handle. It is made from various types of wood. Stores always have assembled axes in stock. But every zealous owner will definitely select hand-friendly and durable tool. In this case, we suggest making it yourself.

The content of the article

Options for making an ax

Wood species are the basis of the product. The material is thoroughly dried. For this purpose, special cameras are used. This will protect the ax from loosening when the temperature changes and loss of moisture. The fibers of the wood structure should be straight, without interlacing.

In recent times, wood was dried on a stove. She was kept warm for several months to evaporate excess moisture.

Basic requirements for the material:

- must be deciduous;

- hardness;

- fracture strength;

- wear resistance.

A high-quality ax handle must be made from well-processed and impregnated material.

Beech

Has a beautiful surface. Easy to cut and process. When properly dried, it becomes a hard and durable material. There is a serious drawback - absorbs moisture strongly. This has a bad effect on wear resistance. Even ordinary oil impregnation will not completely protect the handle.

Oak

Majority craftsmen prefer this type of wood. Especially in the case when a synthetic handle is categorically unacceptable.

Advantages of oak wood:

- Durability.

- Beautiful structure and ease of processing.

- Durability and reliability.

- Impact resistance.

- Moisture resistant.

- Immune to fungi and various pests.

Among disadvantages are highlighted:

- Heavy weight.

- High hardness - dries out your hand when chopping.

In any case, oak is considered one of the best materials for creating a comfortable tool.

Ash

Ancient times spear shafts and battle axes were made from it. Wood best meets the requirements for a handle:

- High density and shock resistance.

- Long service life.

- Hardness.

- Low cost.

The characteristics are similar to oak, but ash has better elasticity. Tool handles and gymnastic bars are made from it.

Birch

It is easy to sand. No recoil or fatigue. The wood is shock resistant. With proper processing, the service life of the ax increases.

Minuses:

- Easily absorbs water.

- Long-term drying (from 1 year).

- Low hardness.

- Rapid rotting.

At the same time, birch is a very elastic material. Easily lends itself to curly cutting.

Maple

There are no problems with it due to its soft structure. Quickly polishes and dries. Does not loosen even with changes in temperature and humidity. Durability is better than oak, and in terms of impact strength it is inferior to birch. Maple makes handles that are strong and beautiful in appearance.

American walnut

His easy to polish and process. It has a hard and viscous structure. For impregnation, linseed oil is used. The ax handle is pleasant to hold in your hands.It maintains its impeccable appearance for a long time.

Jatoba

The wood is hard and tough, stronger than oak. Pliable in processing. Sports accessories, tool handles and furniture are cut from it. All products are beautiful. Masters choose it because of its characteristics and aesthetic qualities.

It is considered an expensive material for an ax handle. Ideal for a gift because it has a solid appearance.

Hickory

In America, wood is used to make the handles of pickaxes, knives and axes. It has strength, elasticity and a long service life. Dries well. It is not in demand in Russia due to the high cost of materials.

Acacia

Due to its strength and hardness, it is suitable for making an ax handle. The surface is difficult to work with your hands, but the result is smooth and attractive. When impregnated with oil maintains polish for a long time.

What is the best material to make an ax handle from?

Those with extraordinary strength are offered oak. The strong and durable material will fit well in your hand and will be a faithful companion for many years.

Who is willing to pay for functionality and aesthetic appearance - it is optimal to choose American walnut and hickory. But in our country it is difficult to find such wood.

If accessibility, efficiency and convenience are a priority, you should pay attention to ash. It is soft and beautiful, will last a sufficient period and is easy to use.

Service life of the ax

Durability depends on the handle's resistance to impact. Gradually it crumples, and the nozzle becomes loose. If it becomes loose, to repair it, the ax is set back and another wedge is driven in. Using a reverse nozzle will help avoid these problems.

The period of operation is determined by the following factors:

- wood type;

- drying quality;

- density of the nozzle.

Anyone can make an ax handle. Knowing the characteristics of the material, it is easy to make a reliable and strong handle. Thanks to this, the ax will last for many years.

Yes. Even before the war, an acquaintance of mine made a handle from birch rhizomes and a technical hand (there was such a profession): he could not determine the type of wood!

Straight-layered wood for the handle is a debatable thesis. At one time, I was recommended by a construction team to make an ax handle from the butt part of a birch tree with heavily intertwined wood fibers. Yes, it is difficult to process, but the result will be a handle without a tendency to split.