What kind of wheels are there for an angle grinder?

Almost every owner has a variety of different tools. But none of them has as many applications as the grinder. It seems like a simple angle grinder, but you just need to install another disc, and the functionality changes. What types of tool attachments are there? In addition to the fact that they come in several sizes, the elements also perform various functions - cutting, polishing, grinding. Let's try to understand this issue in more detail.

The content of the article

Disc sizes for grinders

When choosing the next wheel for an angle grinder, you should check the diameter of the attachment. This external indicator must be within acceptable limits, but not greater.

If the size of the grinder disk according to the documentation should be 125 mm, then 230 mm wheels should obviously not be used. Why? There are reasons for this:

- the cutting edge will move at a higher speed, which will lead to damage to the wheel and, accordingly, injury;

- a compact power tool will not be able to handle work with a larger attachment;

- if you install a disk that is too large, you will have to remove the safety cover, and this already goes against safety regulations.

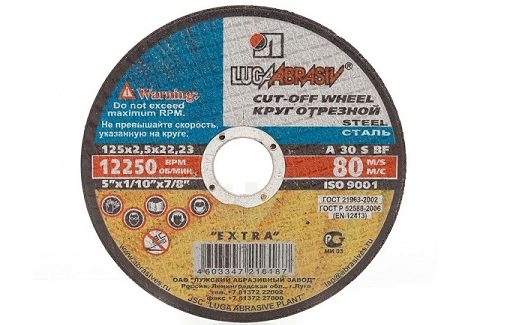

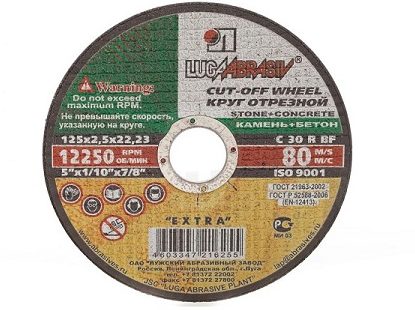

All circles are standardized in their parameters. Their inner diameter is the same. Only the external one is different.The manufacturer applies special markings to all of them, which displays all the necessary information.

Types of discs for grinders

Not only the dimensions distinguish the elements from each other, but also their functional purpose.

Cutting attachments

Most often, a grinder is used to cut something. Naturally, the type of circle is determined by the material with which to work:

- Nozzles for metal. For their production, crystalline corundum alumina and synthetic corundum, which is also called electrocorundum, are used. They are painted blue.

- Circles for cutting stone and concrete. Made from silicon carbide. This abrasive material easily copes not only with sand-lime brick, but even with slate. Some types of concrete can be cut. The green color distinguishes this type of circle.

- For working with ceramic tiles, red brick, porcelain tiles and concrete. Diamond wheels are used. Of course, the nozzle itself is metal. Simply, a mass of abrasive is applied to its cutting surface, to which diamond chips are added. There are two types of discs on sale. Segmented wheels allow dry cutting, solid wheels require cooling with water.

- For cutting wood. Outwardly, they are no different from those used in circular saws, but for safety reasons it is better not to use them. People often get injured from such a tool, since the disc periodically tends to jam, bounce off, and slip off in every possible way.

Attention! If an irresistible need arises to use an angle grinder to cut wood, then this must be done in compliance with all safety measures.The tool must have both a protective casing and an additional handle. The user works only in personal protective equipment: glasses and gloves. Such circles should only be used on wood. But it is better to take disks that are equipped with a chain, like the one used in chainsaws. If the circle is jammed, the chain remains motionless, while the attachment itself rotates idle.

Discs for roughing and stripping

Before covering a surface with fresh paint, the old layer must be removed. Rust also requires preliminary cleaning. For these cases use brushes. There are two types of brushes on sale. They can be disc-shaped or cup-shaped. But in both cases there is a metal wire.

The wire itself is twisted into separate cords or simply fluffed. Its diameter is different. The quality of processing depends on the thickness. If only rough but quick stripping is required, then brushes with thick wire are used.

Grinding and polishing wheels

The original purpose of the grinder is to help a person with grinding and polishing. They can very quickly (albeit roughly) process any surface, but are also used for finishing manipulations. For this purpose, a lot of different grinding and polishing discs have been developed, including:

- Cord brushes for roughing or cleaning.

- End abrasive attachments. For the sides of workpieces.

- Petals. This is a special type of circles that are made from abrasive cloth of varying degrees of grain size. The quality of the result directly depends on the grain size.

- Felt circles.They are used when it is necessary to polish the surface to a mirror state, using polishing liquids or special pastes.

- Fiber nozzles. For metal surfaces.

- Chain and circle planes. For working with wood. To do this, you need to put an additional handle on the grinder.

The sandpaper can be secured with Velcro to the attachment. In this case, it is mounted on the spindle of the angle grinder.

There are many different felt wheels in stores that are used for polishing work.

Milling

Among the wide variety of discs for power tools, you can find options for milling. There are only two varieties of them - classic and cutters. The circles have a side part for working and in appearance it looks like a rasp. They roughly process wood. The cutters not only differ in their shape, but their teeth are located differently. This type of disk works:

- making grooves;

- choosing solid wood from recesses and bowls;

- cleaning the edge and end parts of objects;

- sawing small parts.

Sharpening

For sharpening, ordinary discs are used: they are the same for both grinders and machines. The main thing that distinguishes them from cut-off machines is their thickness, as well as the ability to use the side part for work.

The cross-section of such circles is at least five millimeters. They are used not only when it is necessary to sharpen the cutting edge of a tool, but also to clean surfaces from welding traces, and even if it is necessary to roughly process a part.