How to reduce speed on an angle grinder? Create your own regulator!

The grinder engine, as a rule, operates at a very high speed, gaining 3000-8000 revolutions every minute and even more. But different tasks may require much less power. To do this, make a speed controller for an angle grinder with your own hands. You can make it yourself, and all costs will be extremely insignificant. Step-by-step instructions with photos and descriptions of actions are described in this material.

The content of the article

What you need for work

It is quite possible to make the device yourself. For the work you will need available materials and tools:

- the regulator itself (it can be purchased at a very affordable price);

- soldering iron;

- pliers;

- wire cutters;

- insulating tape;

- Screwdriver Set;

- old power cord with plug;

- a small container with a rigid body, for example, plastic (you can put a regulator here to protect it from water).

Step-by-step instruction

To make a regulator, you need to do this:

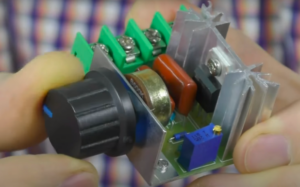

- First you need to purchase the regulator itself. This small device consists of a board, a radiator with a triac. There is a variable resistor that regulates the minimum number of revolutions of the tool. There are also capacitors, input terminals, diodes and a variable resistor (round knob). It is he who serves as the speed regulator for the angle grinder.

- To connect, you can use 2 contacts located in the middle.

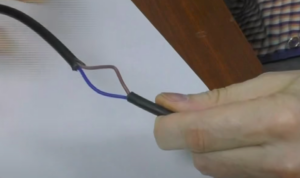

- Use a knife to cut through the insulation of the power cord and get to the wire itself.

- Trim the insulation on both sides - it will look something like this.

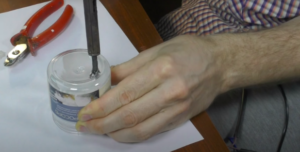

- The next step in the instructions on how to reduce speed on an angle grinder involves making a small hole in a plastic container. This can be done using a hot soldering iron. Moreover, the device should be moved slightly from side to side to increase the size of the hole.

- Insert the wires into the resulting holes - then the speed controller for the angle grinder will be in the container, which will protect it in case of shocks or water ingress.

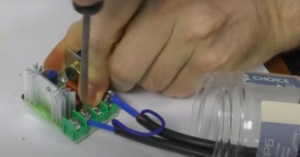

- Remove one screw (center left or right).

- To ensure a smooth start for the angle grinder, you next need to strip the contacts from the wires.

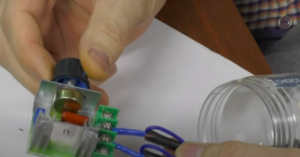

- Twist both wires and wind one of them onto a screw.

- The result should look like this.

- Wind the other wire in the same way.

- Solder both wires with a soldering iron.

- Screw both wires to the regulator.

- The result is like this.

- Test the operation - the angle grinder with a speed controller should start smoothly. Next, you can make 5 turns counterclockwise by tightening the resistor bolt.

- Thanks to this, the engine will gain even less revolutions, which will ensure an even smoother start for the angle grinder.

It is clear that the do-it-yourself soft start scheme for an angle grinder is quite simple. You can adjust the engine speed by tightening the bolt arbitrarily, depending on the task being performed. This will allow you to both reduce the speed on the grinder with your own hands and increase it if necessary.