How to make a wall chaser from a grinder with your own hands? Instructions and drawings

How to make a wall chaser from a grinder with your own hands? This is an atypical question for those who like to use an angle grinder everywhere, but such situations still happen.

A groove is a groove in the wall into which wires are laid. Modern requirements for electrical wiring state that all wires must be hidden in the wall. As a rule, electricians begin their work after the walls are plastered, so they have to cut grooves to lay wires.

Manufacturers of electric tools have long come up with a specialized power tool for creating grooves - a wall chaser. As a rule, professional electricians use it because it allows them to carry out large volumes of work at high speed. But there is no point in buying yourself a wall chaser if you need to lay wires in your only apartment or cottage. Buying a wall chaser simply won’t justify itself, since after the repair is completed, the tool will remain idle, which cannot be said about an angle grinder. In this case, you can use a hammer drill to create grooves, however, this method has a number of disadvantages:

- creates a lot of noise during operation;

- works slower than a wall chaser;

- The grooves turn out sloppy.

That is, it is expensive to purchase a professional wall chaser, and you don’t want to use a hammer drill because of its shortcomings, so simulating a wall chaser from an angle grinder seems to be the most optimal solution.

The content of the article

How to make a wall chaser from a grinder with your own hands

If you have seen a professional wall cutter with your own eyes, then you know that the groove in it appears due to the simultaneous operation of two disks that cut out a groove in the wall. A professional wall cutter is good because it allows you to quite finely adjust the width of the groove by moving the disks closer or further away using a special mechanism or washers, plus it has a special dust removal system.

You won’t be able to make a professional wall chaser out of an angle grinder with your own hands. Or rather, this can be done if you spend a lot of time, effort and money on purchasing additional equipment, for example, a special casing for dust removal. Ultimately, if you count the costs and time, then it turns out that it is better to buy a ready-made wall chaser. At the same time, it is possible to partially modernize almost any angle grinder “for a wall chaser” using improvised means.

How to convert an angle grinder into a wall chaser

To make a wall chaser from a grinder with your own hands, there are two ways:

- use special nozzles;

- remake using available means.

Using special attachments means:

- Buy a special disk attachment for forming grooves. Such disk attachments are easy to find in hardware stores. They are a specialized attachment tool for an angle grinder, which can have different widths. The width of the nozzle disk is the width of the future groove. All you have to do is choose a disk with the required width for the working diameter of your angle grinder.

- Buy a special protective dust extractor cover.As a rule, such a casing is quite wide and is suitable for discs with different widths. The most important thing is that it is possible to connect a professional vacuum cleaner to it, which will suck in dust and small particles when forming grooves.

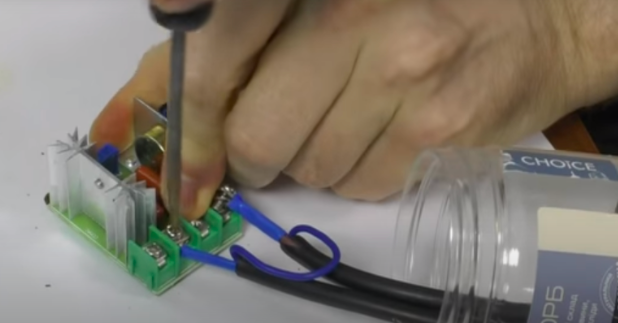

- Replace the standard kit with a kit for gating. There is nothing complicated here: you will need to remove the standard protective cover and install a special one in its place. Then, in the place where the disk is attached, you will need to attach a specialized disk for gating. After this, you can connect a construction vacuum cleaner to the grinder and start working.

If you want to make a wall chaser out of your grinder with your own hands, then the option with factory attachments is the most optimal. The disadvantage of this method is that it requires a trip to the store and the purchase of special equipment.

Not everyone wants to travel somewhere, much less spend extra money. That is why there is another way to convert an angle grinder into a wall chaser - this is to use available means at hand. All you need for this method is another concrete disc and an additional nut to secure the disc. The discs for concrete should be the same, so it is better to use two new ones so that they have the same wear and diameter.

You need:

- Remove the standard protective cover, because in most models of angle grinders it will get in the way. If there is a broader interpretation of it or a special one for gating, then install or leave these.

- Install one disk onto the concrete, securing it with a standard nut. This is the standard procedure for installing a disk. The main thing is not to forget to take into account the working direction of rotation of the disk and the angle grinder.

- Place a second disc on the concrete on top of the nut, again not forgetting about the working direction of rotation, and tighten it with the second nut.

After the second disk is installed, you can consider that you have made a wall chaser out of your angle grinder with your own hands. Despite the simplicity of this method, it has a number of problems.

How to make a wall chaser from a grinder with your own hands: problems

When you use factory attachments to convert an angle grinder into a wall chaser, then there should be no problems. Problems begin to appear when you start messing around with installing an additional disk on the grinder. The problems are this:

- Some models of angle grinders are equipped with a short shaft, on which you cannot install an additional disk in combination with a standard clamping nut. In this case, you can try installing a thinner nut instead of a standard nut, or simply a thin separating washer and clamping both disks with one clamping nut. There is definitely no need to try to “increase” the shaft using artisanal methods, for example, by welding on another “piece of the shaft” - this is very dangerous.

- The width of the groove is not adjustable. The width of the groove will depend on the distance at which you fix the two disks from each other on the grinder. This distance depends on the length of the standard shaft, which means it is very limited. You will be able to cut grooves for wires, but it is unlikely for water pipes.

- No protective cover. If you do not purchase a special protective casing to which you can connect a vacuum cleaner, then be prepared for a lot of dust. Therefore, you need to take care of the availability of protective glasses and a respirator in advance. It is imperative to protect your respiratory and vision organs.Of course, you can make a protective casing yourself from metal and connect an industrial vacuum cleaner to it. But this is additional time and materials spent, plus you need to have welding skills and a welding machine. There are “makeshift” temporary options using plastic bottles or sewer pipes, but these are “one-time” options. It's better to buy a factory one, but it costs money.

- The grinder may burn out. The grinder is not designed for forming grooves. An additional disk means an additional load on the tool, which means the risk of failure increases several times. Therefore, when using an angle grinder as a wall chaser, you need to work without fanaticism and give the tool a “rest.”

Conclusion

Now you know how to make a wall chaser from a grinder with your own hands. From a practical point of view, the most acceptable option is to remake the grinder using factory attachments, because the method with an additional disk has many disadvantages, but the most important thing is that it is dangerous to health.