Types of 3D printers

Not long ago, 3D printers appeared on the electronics market. These devices print any three-dimensional objects. If recently they were practically inaccessible to a wide range of users, now the situation has changed. Existing models can be used in industrial and home environments. They all differ in their characteristics and the printing material used.

The content of the article

Types of 3D printers

All printing devices are divided according to the type of materials used and the 3D printing technology used.

Types of printers by material used:

Powder. ANDpowder is used, you can work with metal powder. The print head of the device applies a special binder to the areas marked by the program. Powder or powder is applied on top of it with a roller, which is sintered with the binder. The procedure is repeated until the final result is obtained. This option can be made independently, having all the necessary components.

Powder. ANDpowder is used, you can work with metal powder. The print head of the device applies a special binder to the areas marked by the program. Powder or powder is applied on top of it with a roller, which is sintered with the binder. The procedure is repeated until the final result is obtained. This option can be made independently, having all the necessary components.- Plaster. Powder is also used for work - putty, gypsum, cement and other substances. A binder material is also used. Finished products can have a wide variety of shapes.

- Photopolymer. Special liquid substances are used for the work. The very principle of work is very similar to the creation of sculpture. The laser of the device focuses on the prepared computer model and highlights the required areas.

- Wax.The material used is ordinary wax. Thanks to its plasticity, the result obtained is very accurate.

REFERENCE. If a photographic printer is used, the result will be highly accurate in detail. However, such a device works very slowly.

Types of equipment

In addition to the fact that all devices use different materials for their work, they also use different technologies for printing.

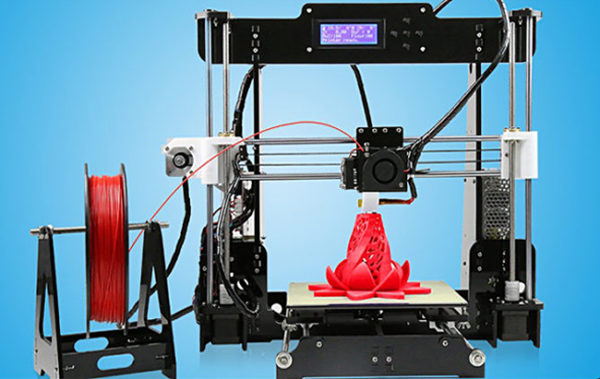

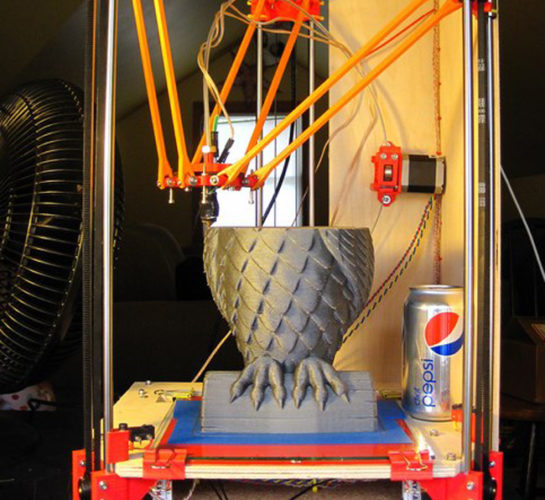

FDM technology

These are the most inexpensive and widely used devices for 3D printing. The principle is based on layer-by-layer application of plastic thread. They have the following advantages:

- inexpensive cost;

- will be the best option for getting acquainted with 3D printing technology;

- easy to manage and configure.

Disadvantages include:

- they do not have a closed chamber, which makes the design not very reliable;

- the open chamber limits the types of plastics the product can work with.

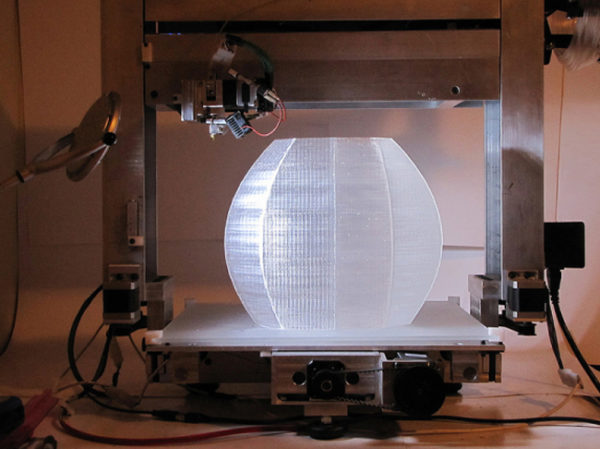

SLA printing method

Such devices appeared on the market relatively recently. The operating principle is based on laser stereolithography. The material used is a resin that hardens when exposed to light.

The advantages are:

- high quality of the finished product;

- very accurate reproduction of the smallest details.

Flaws:

- slow work process;

- a small number of colors that the printing device works with;

- high cost of the product.

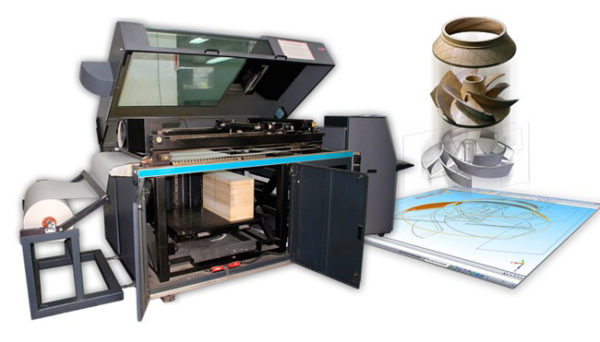

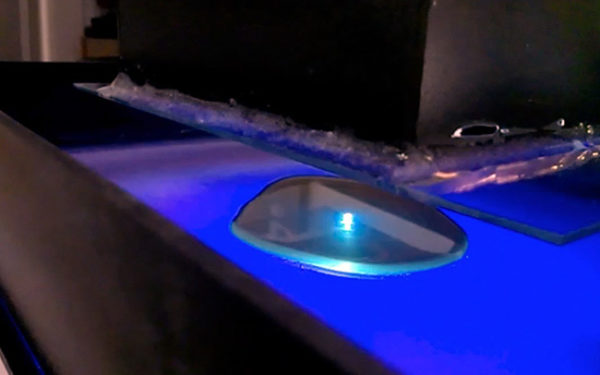

Polyjet

For work, photopolymers are used, which are applied in small doses to the surface of the 3D printer, after which they polymerize under the influence of ultraviolet radiation.

Advantages:

- fast printing process;

- various materials can be used;

- the material is applied in a thin layer, which ensures high accuracy.

Minuses:

- The photopolymer used is an expensive material, and quite fragile.

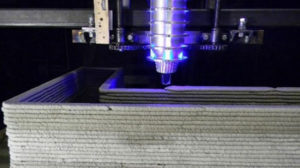

LENS

It is a powder version of a 3D printer. The powder is applied to the surface of the device and then processed with a laser. Under the influence of its rays, the material is baked.

Pros:

- can print parts made of steel and titanium, so LENS printers are widely used in industry;

- The materials used can be mixed, thanks to this you can instantly obtain the necessary alloys.

Minuses:

- narrow application.

LOM

Ready-made laminated sheets are used for work. Using a laser, the required object is cut out on them, and the sheets themselves are glued together.

Advantages:

- finished products have a very low cost because the materials used are inexpensive and easily available.

Flaws:

- low accuracy of finished objects;

- a large amount of waste.

SLS

The material used is powder. It is applied with a special roller to areas specified by the program. The procedure is repeated until the desired object is obtained. After completion of the work, the finished model is removed and placed in a booth to remove any remaining powder. Next, the model is covered with glue.

The advantage of this option is virtually waste-free production.

3DP

This is a powder type 3D printer. The material is covered with a layer of glue that glues the powder granules together. The procedure is repeated the required number of times.

Advantages:

- Various coloring pigments can be added to the glue, which allows you to print color models;

- low-cost production;

- any powdery substance can be used;

- With this device you can print edible objects.

Minuses:

- low quality of the finished object;

- Additional processing, baking, is required to impart the desired properties.

The new technology for printing three-dimensional models attracts a large number of people. 3D printers are quite easy to learn and are suitable even for those who do not have relevant work experience.

When choosing the most suitable device, you should consider what the device will be used for. For a beginner, an inexpensive product with a minimum of functions is suitable. Whereas for a designer - a device equipped with several print heads.