Laser printer cartridge device

The laser printer has been an integral part of office life for more than 20 years - a place where fast, large-volume everyday work is needed. The external simplicity of the design hides mechanisms and complex technological components under the body. The main component of devices of this design include laser cartridges, which use not ink, but toner—dye powder—to produce images. To better understand how a laser printer works, you must first disassemble the components that make it up and understand their purpose.

The laser printer has been an integral part of office life for more than 20 years - a place where fast, large-volume everyday work is needed. The external simplicity of the design hides mechanisms and complex technological components under the body. The main component of devices of this design include laser cartridges, which use not ink, but toner—dye powder—to produce images. To better understand how a laser printer works, you must first disassemble the components that make it up and understand their purpose.

The content of the article

How does a laser printer cartridge work?

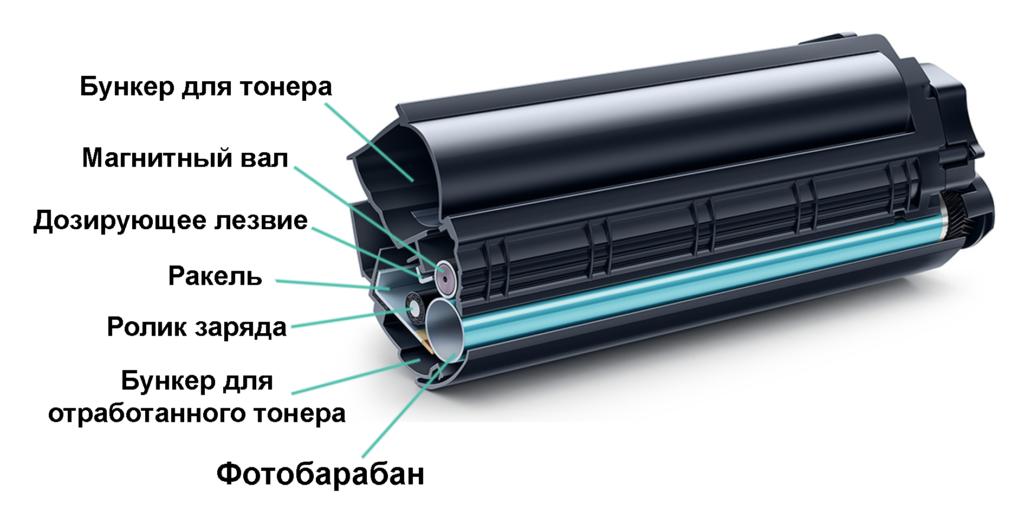

The body of a laser printing device consists of two main blocks fastened together: on top there is a container for waste toner, and on the bottom there is a container for paint.

Top includes:

- photoshaft – a hollow cylinder with a surface made of photoconductive material;

- a metal shaft that provides a negative charge to the photo shaft;

- cleaning blade (squeegee);

- container for waste toner.

The toner compartment, which is the bottom part, includes:

- Magnetic type shaft (developer). It consists of a shell and a core that has a positive charge. It attracts particles of coloring powder after exposure to a certain voltage. Charged negatively.

- Dosing blade (doctor). To ensure uniform distribution of paint on the shaft.

- Container for primary toner.

- Security seal.Prevents powder from spilling during transportation.

Laser printing principle

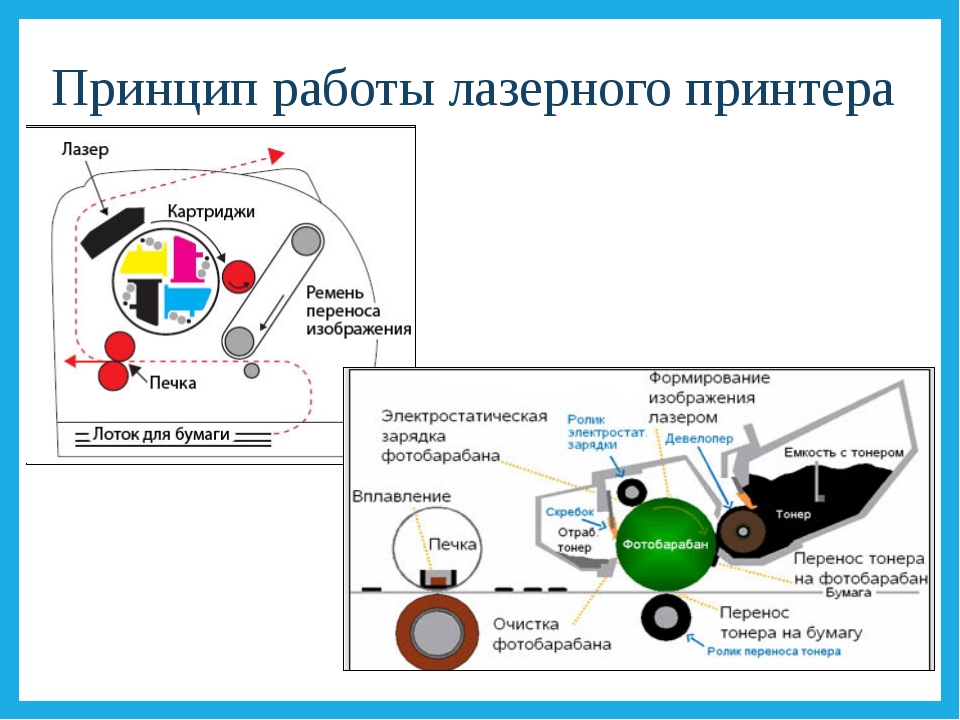

The principle of laser printing is as follows. The basis of the device is a photoconductive shaft. It allows you to transfer the image to a medium. This shaft, coated with a photosensitive layer, is a hollow cylinder with a charged surface. Until a beam of light hits the surface, the charge remains.

Another, no less significant part of the device is the laser, optical-mechanical system of mirrors and lenses. This mechanism moves a thin and “sharp” beam emitted by a quantum generator (laser) along the surface of the shaft. There is a reflection from a system of four-hexagonal mirrors, illumination of a certain surface of the drum, more precisely, its photosensitive coating. When a certain area is exposed, the surface becomes conductive and the charge “drains” from this area. Where the charge is removed, a neutral zone is formed.

The effect of the pole difference (plus or minus) causes the powder particles to adhere to the shaft. As a result, its negatively charged particles stick to the area illuminated by the beam. The ink toner, located on a rotating shaft, comes out through a narrow opening and is evenly distributed by the metering blade.

Turning the laser on and off by the control microcontroller forms a dot image. With the help of a rotating system of mirrors, the light beam is unfolded and image lines are formed on the surface of the photodrum.

As the line is formed, the stepper motor turns the drum, and the next line is formed. Next, the process is repeated many times until the entire picture is “painted”.

The final stage is transferring the paint to the sheet. The drum with the printed image continues to rotate. It is negatively charged. Gradually it reaches the surface of the leaf. He, on the other hand, comes into contact with a positively charged shaft. Paint particles are attracted to the paper. This is how images are transferred.

The principle of printing an image with a laser printer must be understood not so much for proper operation, but for eliminating and preventing problems that arise during operation.