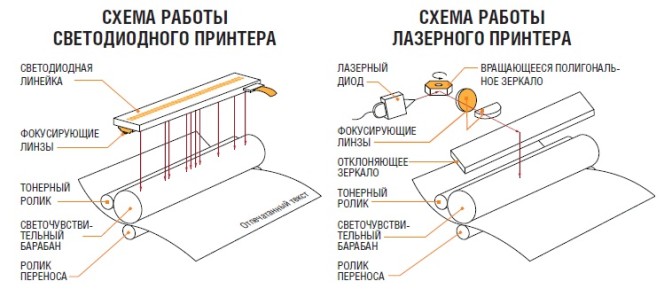

LED printers - operating principle

LED printing began to be used in the 80s. The technology has replaced expensive laser equipment. Printing is carried out using a photographic method. The difference from laser devices is the method of illuminating the sensitive drum. In LED models, the ruler is located along the surface of the shaft, ensuring uniform flow distribution. Due to its design features, this equipment is more reliable than its analogues. Such printers are capable of providing high quality images.

The content of the article

How does an LED printer work?

The operating principles of LED equipment are similar to those of laser models.

Device

- The photo shaft is the basis of the design.

- On its surface there are semiconductors that react to light.

- When light from the diodes hits the area, the resistance changes and a primary image appears on the paper.

- Next, the ink toner particles are attracted by the opposite charge. And under the influence of high temperatures they fix their position.

REFERENCE. The material of the sensing shaft affects the formation of the charge. The most commonly used models are those with a negative charge.

Basic printing steps

- Paper is fed into the device using pressure rollers.During the process, the sheet is flattened and prepared for image reproduction.

- At the same time, charge accumulates on the drum. For this, a corotron or a charging shaft is used.

- The LED strip begins to light up in the areas where the image needs to be applied. Control is carried out using the main control unit.

- The toner is then attracted to the highlighted areas. To fix it, high pressure and temperature are used.

- The result is a sheet with a finished image that is resistant to external influences.

Color printing methods

The color LED printer prepares the image before printing. Using a raster processor, the image is divided into four primary colors.

IMPORTANT. Separate cylinders are used to print each color. If necessary, shades are mixed.

- The one-pass method is used in modern models. Processing and application of the image occurs in one pass along the shafts.

- The multi-pass technique contains an intermediate section on which the image is applied separately and then transferred to paper.

Types of LED printers and their capabilities

All printing devices can be divided into several groups. These include monochrome and color equipment, as well as devices with spherical toner. The main difference is the structure of the printing substance. When exposed to high temperatures, the core of the toner elements begins to melt first. The resulting mass easily saturates the paper.

ATTENTION! Spherical particles allow you to make clearer contours of points. Therefore, the image quality becomes better.

Features of LED Printers

Monochrome

This equipment has a simple design.Due to the fact that the cartridge and the sensitive drum are separated, it is possible to replace the elements separately.

LED

Such printers are compact in size and lower in cost. The devices are safe to print and do not make noise.

The printer design contains 25,0010,000 diodes, depending on the resolution of the product. The service life of LED lamps is higher than that of lasers and lenses in similar models.

Colored

These printers allow you to print high-quality, high-resolution images. This ensures more accurate rendering of text and small details.

Four basic colors are used: yellow, black, blue and crimson. Processing speed depends on the model.

REFERENCE! The limit is 36 A4 sheets per minute. The maximum monthly load should not exceed 150,000 copies.

Due to the absence of rotating mechanisms, LED printers are more reliable.

This technology is an effective alternative to laser printing. The printers are easy to use and do not require specialized maintenance. Under the right operating conditions, the products will provide high-quality printing for a long period.