How a laser printer works

Laser printers are widely used for printing documentation in the office and at home. High print quality and speed of operation are due to the design features. In order to understand the principle of operation of the equipment, it is necessary to study the device in detail. It will not be possible to briefly examine this question, but the more detailed we look at everything, the clearer the answer will be.

The content of the article

Laser printer device

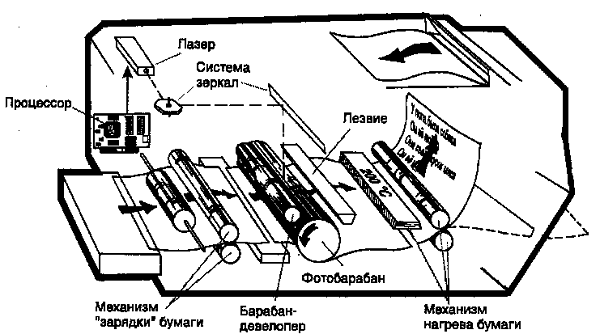

The operation of a laser printer is based on the photoelectric principle of xerography. The design includes complex mechanisms and components, which can be divided into three main blocks.

- It is based on a printing mechanism.

- A controller with a raster processor is responsible for scanning.

- Data exchange is carried out using an interface block.

Elements of the printing mechanism:

- photodrum with a static charge that changes depending on the lighting;

- a laser and a system of mirrors ensures that certain areas on the photodrum are illuminated;

- an intermediate block necessary to transfer the image to the final medium;

- a toner storage and supply unit based on a cartridge;

- mechanisms for drawing paper from the tray to the print head;

- heating elements for developing the image on the sheet.

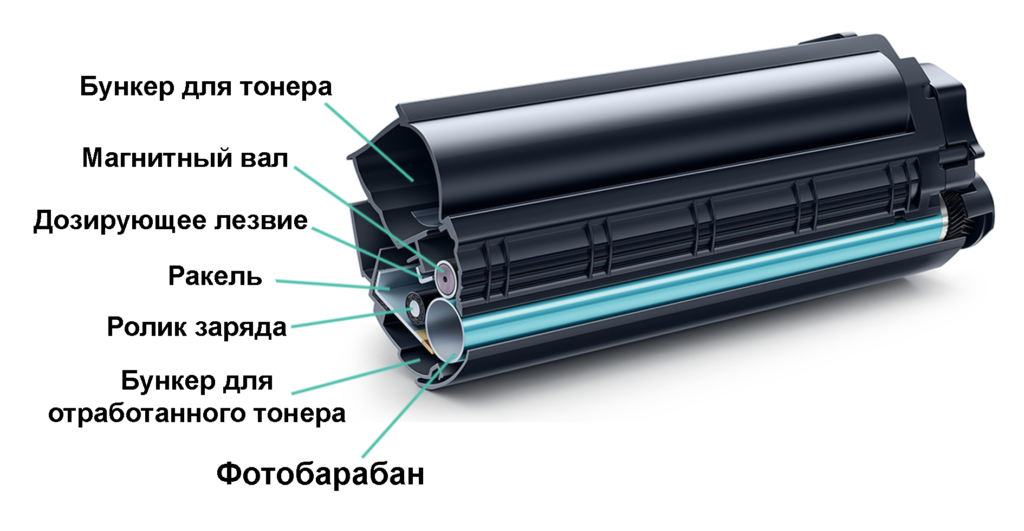

How the cartridge works

The cartridge consists of a toner and a drum. The chemical composition of toner is a crushed polymer material. Powders differ in consistency and physical properties depending on the manufacturer. Toner differs from ink in the quality of the resulting image, but you must be careful when working with it.

Important. For high-quality printing on a laser printer, it is necessary to change consumables on time. It is not recommended to refill low-quality toner cartridges.

The drum is a cylinder with a photoconductive surface. The magnetic roller recharges the toner and the cleaning blade removes unused toner.

How does a laser printer work?

The operating principle of a laser printer is to create a preliminary image on a drum and then transfer it to paper. A high-quality print is obtained by applying dots to the photodrum using a laser and a system of mirrors. The operating principle of a laser printer is based on the physical process of xerography.

To understand how the device prints, you need to study in detail the stages and operating principle of a laser printer:

- Image processing and charging the drum with charged particles.

- Next comes the preliminary creation of the image.

- The next step involves developing with toner.

Fixing occurs using high temperatures. The design ensures high print quality and speed. Technology is constantly evolving, offering new solutions.

Drum charge

In order to form a preliminary image, it is necessary to create an electric charge on the surface of the drum.There may be positive and negative particles, depending on the printer model and design features.

There are two ways to transfer charge:

- The corona wire is a tungsten filament containing inclusions of gold or platinum. Under the influence of voltage, an electric field is created, which is transferred to the drum. With this method, the quality of the printed material deteriorates over time.

- The charge roller is a shaft with a layer of rubber or foam applied to it. When interacting with the drum, electricity is transmitted. This method creates a reduced voltage, which allows you to extend the service life of complex mechanisms.

Exhibition

The process of creating a preliminary image on the image drum is called exposure. On the surface of the drum there is a semiconductor coating, which, when exposed to light, begins to conduct current. Lighting comes from a thin laser beam and a complex system of mirrors.

According to the given parameters, the beam forms an image, removing the charge in the exposed areas. Drawing or text is applied pointwise. The result is a surface of negatively charged particles. The drum rotates using a stepper motor. The dots are drawn along the entire circle.

Development

The image is developed using toner and a magnetic roller. The mechanism is a metal tube with a magnetic core. By rotating, the toner is attracted to the shaft. The metering blade ensures even distribution of paint over the entire surface. The layer is formed by passing toner through the gap between the blade and the drum.

Attention: It is necessary to install the mechanism correctly to avoid defects on the printed document. Excess toner results in dots and streaks.

The magnetic shaft operates cyclically. As it works, new particles are attracted, creating an image. Excess powder is dumped into a special container.

Transfer

The image is also transferred to paper using a charge. Moving mechanisms feed the sheet from the tray to the photodrum, next to which there is a shaft for transferring the image. Toner particles are transferred through the circuit to the paper medium due to static voltage. Excess paint goes back into the hopper. Using special elements, dust and small particles are removed from the surface of the sheet. The charge is restored after a whole cycle using a corotron. The process is then repeated until the entire image is transferred to paper.

The image is also transferred to paper using a charge. Moving mechanisms feed the sheet from the tray to the photodrum, next to which there is a shaft for transferring the image. Toner particles are transferred through the circuit to the paper medium due to static voltage. Excess paint goes back into the hopper. Using special elements, dust and small particles are removed from the surface of the sheet. The charge is restored after a whole cycle using a corotron. The process is then repeated until the entire image is transferred to paper.

Consolidation

The next stage of printing on a laser printer is consolidation. This stage is necessary so that the image remains on the paper. Under the influence of high temperatures, the toner begins to melt, which allows it to firmly adhere to the surface. When the sheet passes between two rollers, heating occurs.

Reference. Depending on the model, the stove can heat the powder up to 200–350 °C.

Type of heating:

- Thermal film is used in inexpensive laser printers. It is highly susceptible to mechanical stress.

- The Teflon design heats the surface using a lamp. Reliable and durable design.

Temperature control occurs using a sensor. If the values are exceeded, the device automatically turns off. To prevent the sheet from sticking to the drum, there is a separating mechanism at the outlet.If the basic operating rules are followed, these elements rarely fail.

Color print

Laser color printing is widely used to print high-quality images. Taking into account the fact that the printer creates a subtractive color model, it is possible to obtain any shade. This occurs due to the absorption and reflection of different light waves. When black is introduced, the output is rich colors. A laser printer consists of a large number of modules and blocks that allow you to mix colors and transfer an image onto a sheet. Models differ in technical characteristics and operating principle.

What printing principle is used in color laser printers?

Unlike a black and white printer, the operating principle of color equipment is different. Before printing begins, the printer processes the image and splits it into monochrome. There are four primary colors used: cyan, magenta, yellow and black. Each of them has a separate compartment. During the printing process, the shades are mixed. Models differ in design and principle of operation.

Color printing methods:

In the first case, the image is formed for each individual color. Printing occurs in several passes, which affects the speed of document processing. Due to their design features, such printers have large dimensions.

In the first case, the image is formed for each individual color. Printing occurs in several passes, which affects the speed of document processing. Due to their design features, such printers have large dimensions.- Modern models allow you to simultaneously apply all four primary colors to the photodrum. The image is transferred to the sheet in one pass. As a result of sequential runs, printing time is reduced without sacrificing image quality. This method allows you to achieve more even color rendering.

A color laser printer is a high-tech device.The product, as a rule, has its own processor and HDD. The technology of image transfer to the intermediate section is widely used. The method allows you to extend the service life of the product, since there is no contact between the printing mechanism and the paper. Such devices are suitable for use in the office and at home.