Custom Fluid Composition for Inkjet Printers

Flushing fluids are an indispensable tool when it comes to cleaning cartridges and print heads (PG) of printers. You can find them on store shelves with consumables or try to make them yourself. The article will talk about the composition of the wash, how to prepare it yourself and use it correctly.

Flushing fluids are an indispensable tool when it comes to cleaning cartridges and print heads (PG) of printers. You can find them on store shelves with consumables or try to make them yourself. The article will talk about the composition of the wash, how to prepare it yourself and use it correctly.

The content of the article

Custom composition of professional printer flushing fluids

A special feature of the composition of the purchased washing liquid is that it is almost identical to the composition of the ink itself used for printing. Thanks to this, it is possible to avoid the rapid loss of pigment sediment. Such a deposit forms in any case, since the paint has a very limited shelf life, usually 12 months. The option of diluting it will not be the best - sediment will still form.

The following brands are most popular among users:

- Inktec. It is used for cleaning cartridges and inkjet printers of the Epson and Canon brands. A signal indicating the need to use such a liquid can be poor printing - when one of the colors is not printed (we are talking about color printing).Devices left idle for a long time are also a reason to use flushing. The shelf life of the liquid is 24 months.

- OCP flushes. Another option used to clean print heads. The liquid is packaged in small bottles of 100 ml each. It is valid for 24 months.

Reference! Liquids purchased in a store or made by yourself are also suitable for preserving printing equipment.

How to make your own flushing fluid

A simple way to clean the printer is to use distilled water heated to 50–60°C. It will be possible to cope with the task only if the equipment has been idle for no longer than 2–3 months.

In case of longer interruptions in operation, the flushing liquid will have to be improved with additional components. There are several options here:

- Neutral washing. It can be used to tidy up the printing elements of devices of any brand. The solution contains distilled water (80% of the total volume), ethyl alcohol (10%) and glycerin (10%).

- Alkaline washing. It is often used by owners of Epson and Canon brand devices. For preparation, the same components are used as for neutral washing, but an ammonia aqueous solution is also added (10% of the total volume). Accordingly, the amount of water is reduced (70% is taken).

- Acid washing. A good option for cleaning Hewlett-Packard (HP for short) printers. In addition to distilled water (80%) and ethyl alcohol (10%), the composition includes acetic acid (another 10% of the total volume).

Another way to prepare washing liquid yourself involves using a glass and mirror cleaner. Suitable products are those that contain isopropyl alcohol and aqueous ammonia.

These components can soften dried drops of ink on the printer head. To prepare, you will need distilled water and cleaning agent in a ratio of 9:1. The accuracy of the proportions can be maintained when using a large-volume medical syringe. If you are unable to clean the head, you can increase the amount of cleaning agent in the mixture and try again.

Attention! The maximum permissible amount of glass and mirror cleaner in the cleaning composition is 50%. Excess may lead to the dissolution of the special sealant and print nozzle elements present in the printer head, and, as a result, to equipment failure.

You can avoid the unpleasant consequences of using homemade liquids by doing a little checking. A couple of drops of printer ink are mixed with the prepared composition and left for several hours. If, as a result, the ink goes from a liquid to a viscous state, then it is better to abandon the use of washing and look for an alternative option.

What is flushing fluid needed for and how to use it

Liquid for cleaning printing elements of home and office equipment is useful in a number of cases:

- If you need to rid the cartridge of remnants of previously used ink. This step should be performed before refilling new ink, especially those made by another manufacturer.

- When you need to solve a problem with clogged print head nozzles. Homemade or purchased products are used after the standard cleaning method has not brought the desired result. Dried paint is dissolved by washing and the function of the head is restored.

- If other parts of the equipment are contaminated by ink splashes and should be cleaned.

There are two options for using washing – with and without a special ultrasonic bath. The first option involves the following sequence of actions:

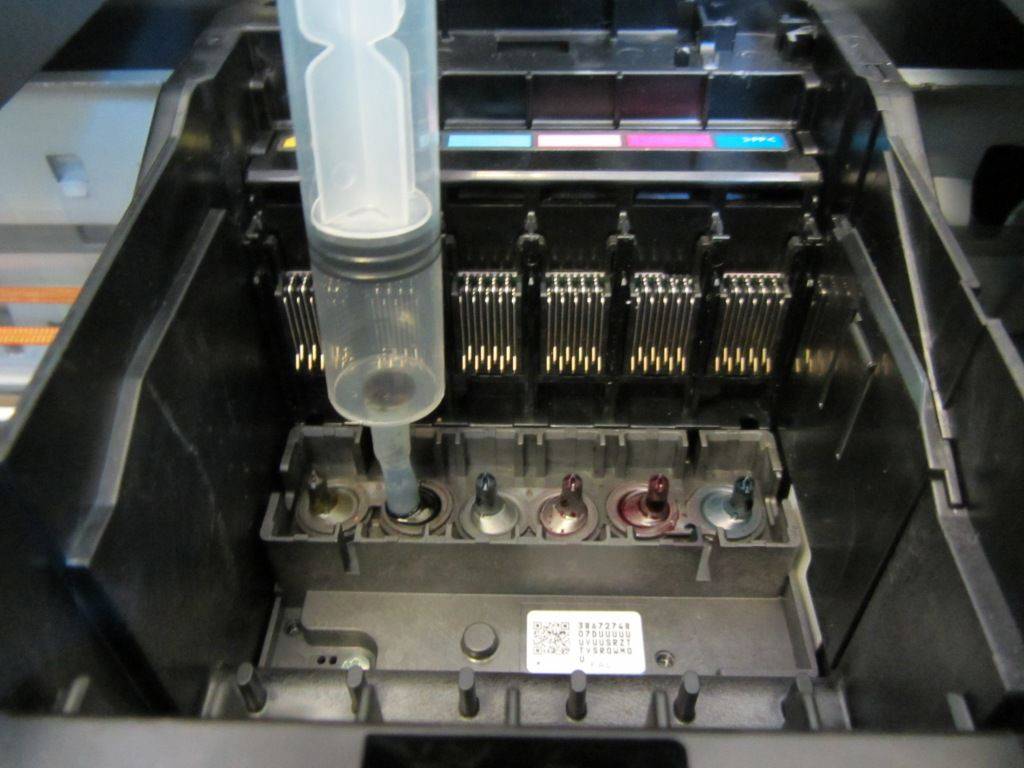

- the print head is removed and placed in 1 cm of cleaning liquid (for 2–3 minutes);

- the element is transferred to an ultrasonic bath pre-filled with distilled water and left there for 5 seconds;

- Using a filling station and a syringe, about 1 ml of ink is drawn out of the PG;

- dirt and ink are removed with a napkin;

- the printing element is returned to its place, routine cleaning is done and a test pattern is printed.

If necessary, repeat the procedure.

The second option looks like this:

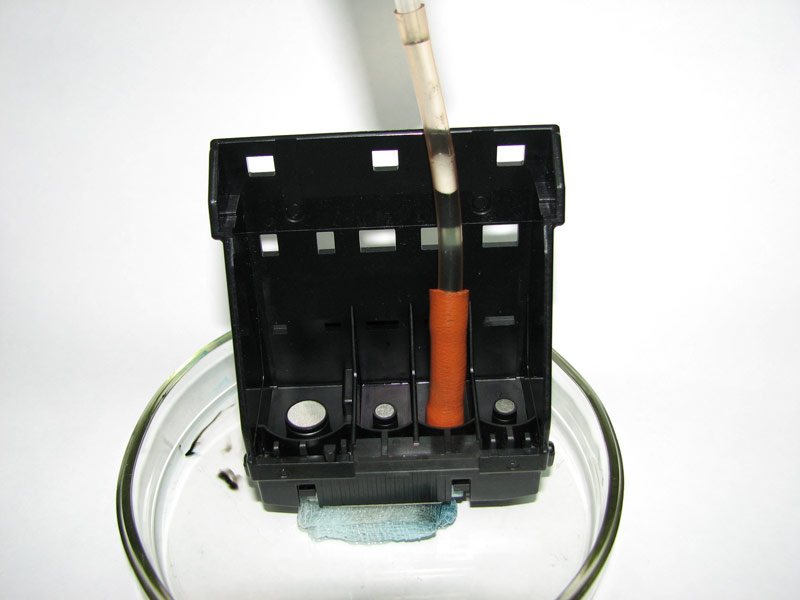

- the removed head is placed in a container with warm water (approximately 50°C) and kept there for about 5 minutes;

- the element is placed for 10 minutes in another container (with washing liquid) so that it is immersed in the composition by 1 cm;

- 1 ml of ink is pumped out from the PG;

- ink and dirt are removed from the surface with a napkin;

- The PG is installed back into the printer, routine cleaning is done and a test print is carried out.

If the desired effect was not achieved the first time, the procedure is repeated (sometimes 3 times in a row).

The washing liquid is a solution whose main task is to effectively clean the printing elements of printers and MFPs. Timely cleaning extends the life of any equipment.