Plastic does not stick to the 3D printer bed

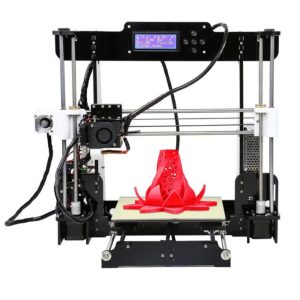

Recently, leading manufacturers presented special printers, printing parts, figures and various elements in 3D format. This type of equipment is very complexly designed, and its operating characteristics correspond to the latest achievements in the field of high technology. In order to properly maintain equipment, you need to understand the principle of its operation and internal design.

Recently, leading manufacturers presented special printers, printing parts, figures and various elements in 3D format. This type of equipment is very complexly designed, and its operating characteristics correspond to the latest achievements in the field of high technology. In order to properly maintain equipment, you need to understand the principle of its operation and internal design.

For regular printing, just read the instructions and operating instructions for the device. It describes a detailed action plan for turning on and pairing with a computer. But sometimes during operation various problems may arise, the solution of which may require serious repairs. Today we will talk about one of the common problems in printing 3D parts. We are talking about poor adhesion of the material to the printer table. This problem interferes with the creation of parts and disrupts the operation of the entire device.

The content of the article

Features of 3D printing using PLA and ABS

In order to print, you need a special polymer material. Different materials are used to work on different printer models. To understand what material needs to be used for your equipment, check with specialists or a consultant in the store.

The most common polymers for printing are PLA and ABS, the features of which include the following characteristics:

- made from natural materials - ABS from petroleum, and PLA from agricultural crops and their products;

- are easy to process and can take on a variety of shapes and sizes specified by the program;

- capable of coloring and changing the degree of transparency of the product;

- strength, while maintaining the plasticity of parts;

- solubility - allows you to glue parts and smooth the edges of workpieces.

Also a distinctive feature is the good fusibility of the material. However, the low melting point is a disadvantage and can ruin the quality of the printed part.

ATTENTION! If the first layer of the workpiece spreads or extends far beyond the table, the structure will also have a poor shape in the future. It is better to stop work immediately and start again.

What to do if PLA peels off from the printer bed

If you encounter a similar problem: the part does not stick to the table surface during operation, you need to try the following:

- Adjust the temperature supplied from the nozzle. With strong heating, the lower layers can melt, which harms the entire structure.

- Set the minimum allowable distance from the table to the printing press. The height should not be less than the nozzle diameter.

- Calibrate and adjust the print head for the first layer. If the part does not attach to the table, change the pressure and the amount of material fed to the lower layers.

- Select and replace the table. It is better to choose a material with good adhesion (sticking): cardboard, beer, plexiglass.

- Try printing the first levels solid to create a special substrate on which the future part will be attached. At the end of the work, you can carefully remove the lower layers and edges.

- Make sure that the workpiece does not extend beyond the working area. Reduce the size of the figure or expand the field.

If there is no effect, you can change the system settings when printing. But, most likely, you will have to contact an equipment repair specialist. Describe the problem, use the warranty for free diagnostics and troubleshooting.