How to choose a 3D printer

Choosing a device for 3D printing is not the most trivial task. This choice should be approached carefully.

In order not to make a mistake with your choice, you need to clearly define what this printer is needed for and what will be printed on it. Based on this, you should select the necessary model.

IMPORTANT. You should know that 3D printing devices are not intended for mass replication of a particular product. This can be useful if you need to create a prototype of a part or print a small part. This may bring in some income.

If you know exactly for what purpose you are purchasing such a device, decide on the plastic for the task at hand.

IMPORTANT. Modern models have color displays, the ability to connect via a local network or Wi-Fi, and many are equipped with a webcam to make it possible to monitor work remotely. The platform is automatically calibrated. This functionality is very convenient, but it does not in any way affect how quality the print will be.

All plastics that are used for printing are divided into two groups. The first group includes ABS plastics, and the second includes PLA plastics. When choosing a printer, an important point will be plastic, since they differ in their properties and printing technology.

IMPORTANT. If you plan to print with ABS plastic, then you need to take into account that it requires a hermetically sealed chamber and a heated table.

For PLA plastic, heating the table is not important, but it requires good airflow.

The content of the article

What is a 3D printer and what is it for?

A three-dimensional printer is considered to be a device that, based on a computer 3D model, recreates an object; the object is formed by applying layers of quickly hardening material. The prototype model can be prepared in any editor. All printers that currently exist are divided into different categories:

A three-dimensional printer is considered to be a device that, based on a computer 3D model, recreates an object; the object is formed by applying layers of quickly hardening material. The prototype model can be prepared in any editor. All printers that currently exist are divided into different categories:

- FDM and DIW use the extrusion method in their work. The liquid material is squeezed out through a thin nozzle. The main difference is in the material used. In the first case, it is molten plastic; in the second type of printer, ceramic slurry is used;

- printers belonging to the SLA-DLP type operate based on the photopolymerization technique. The liquid polymer supplied by the device is hardened layer by layer by ultraviolet laser treatment;

- EBF 3D printers include devices that use wire that is melted by electronic radiation;

- the next type applies the film layer by layer and in each layer of this film the contour of the part is cut with a laser;

- there are devices that precisely supply powder and melt it with a laser (or using electromagnetic radiation);

- There are printers that use multi-jet printing techniques, where you can print not just one, but several colors at once;

- Bioprinters belong to a special category. These devices are just going through the stage of development and implementation. Their purpose is to print human internal organs based on living cells.

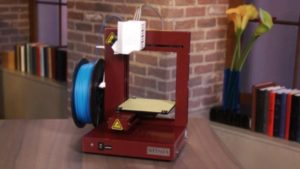

How to choose a 3D printer for home use.

Although 3D printing devices are becoming more and more common, their price still remains quite high.Therefore, in order to use such a device at home, there is no point in purchasing it. It will be enough to stop at the level of three thousand. The choice will depend on financial capabilities and the requirements for print quality.

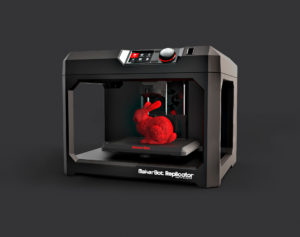

A home 3D printer should have a simple, user-friendly interface and a good balance between price and quality. Home use devices can be divided into categories:

- Budget models include those that range from three hundred to a thousand dollars;

- models up to one and a half thousand dollars belong to the middle class;

- high-end printers, but with an affordable price of up to three thousand dollars.

The most common models include the following:

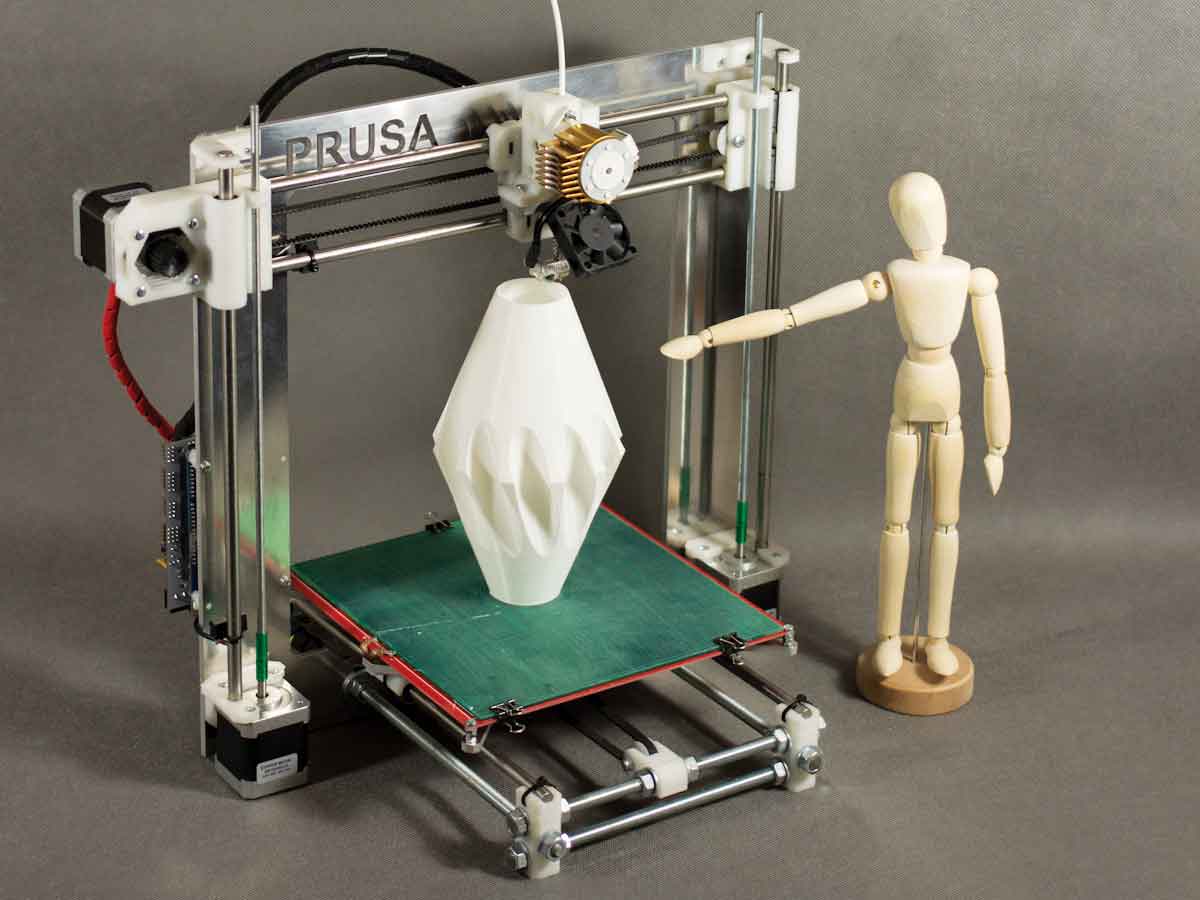

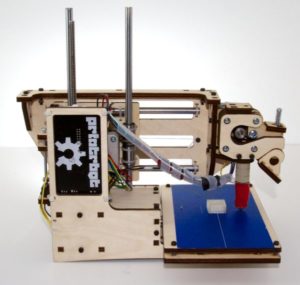

- Printrbot Simple. This model costs $300 and is sold as a construction set that must be assembled. This approach makes the model more compact for transportation and helps to better understand the principle and mechanics of the device;

- Kino XYZ printing da Vinci 1.0 Brand new model produced by XYZ printing. The printer is characterized by high print resolution, comparable to higher-end models. When working, the principle of layer-by-layer printing with molten plastic is used;

- Cubify CubeX. Already belongs to the middle class. The price of this device is $1,300. Characterized by good print quality and high speed of model creation. There are three versions of this model available for sale, differing in the number of extruders.

- Afinia H-Series H479. This device is characterized by high printing accuracy, user-friendly software, and the object is printed using ABS plastic filament. The price of this model is one and a half thousand dollars.

3D printer in small business

Three-dimensional printing is one of the most promising areas in small business today. Using these devices, you can easily set up the production of small batches of different goods. It does not require large financial investments.

But in order to be successful in such a business, you need to choose the right printer model. The most suitable ones will be those that meet the requirements:

- The device must have high print quality, which will ensure the creation of a realistic model, and this automatically eliminates all devices cheaper than a thousand dollars;

- must be able to print in color (such devices include FDM, DIW, 3DP and EBF printers);

- the printer must be able to use at least two types of plastic (PLA AND ABS). This will expand work opportunities and produce children's products. PLA plastic, as it is more environmentally friendly, is intended specifically for creating children's products;

- the cost of consumables for 3D printing should be such that the final production is profitable;

- The dimensions of the chamber must correspond to the intended production.

But in any case, the final choice rests entirely with the user and depends on the business that you plan to engage in. For small crafts, extrusion printers are quite suitable. And for the jewelry industry or dentistry, photopolymer devices are needed.

Conclusion

3D printers have enormous development potential. But, like any technology, it has its own advantages and disadvantages.

Main positive qualities:

- high speed of work, low labor intensity of the process.One printer can replace an entire production line of machine tools and other expensive equipment;

- space for creativity, you can recreate any object on a printer;

- efficiency;

- can be used in medicine in the production of prostheses and implants.

Existing disadvantages:

- high price;

- size limitation;

- danger of printing weapons.