How does a 3D printer work?

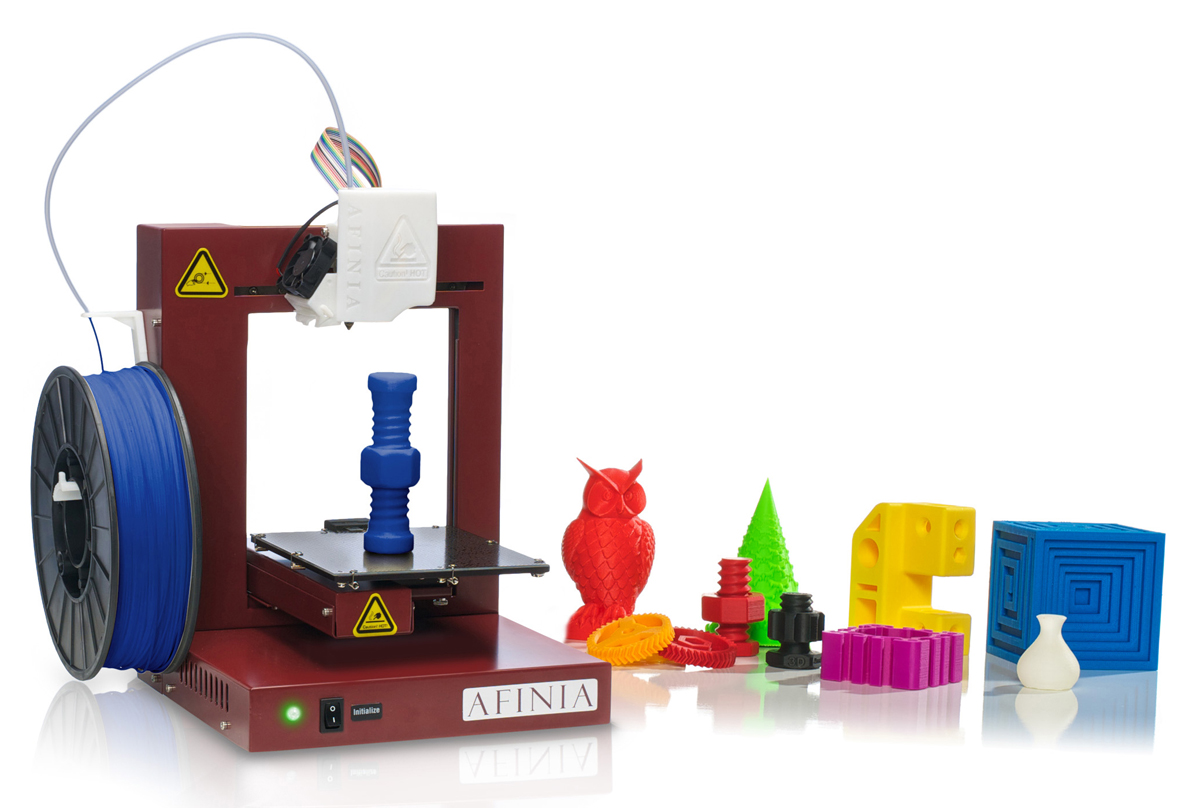

The emergence of printers that allow printing in three-dimensional format has significantly expanded a person’s capabilities in various fields of activity. Now you can create various parts of any complexity and configuration at home. In this case, polymer materials are used for work, which can be easily bought in a store or ordered online.

The emergence of printers that allow printing in three-dimensional format has significantly expanded a person’s capabilities in various fields of activity. Now you can create various parts of any complexity and configuration at home. In this case, polymer materials are used for work, which can be easily bought in a store or ordered online.

However, the printing process itself is a complex sequence of actions. In order to understand modern technologies and use the device correctly, you need to know its operating principle. You can find out more about this in our article.

The content of the article

What is a 3D printer, how does it work?

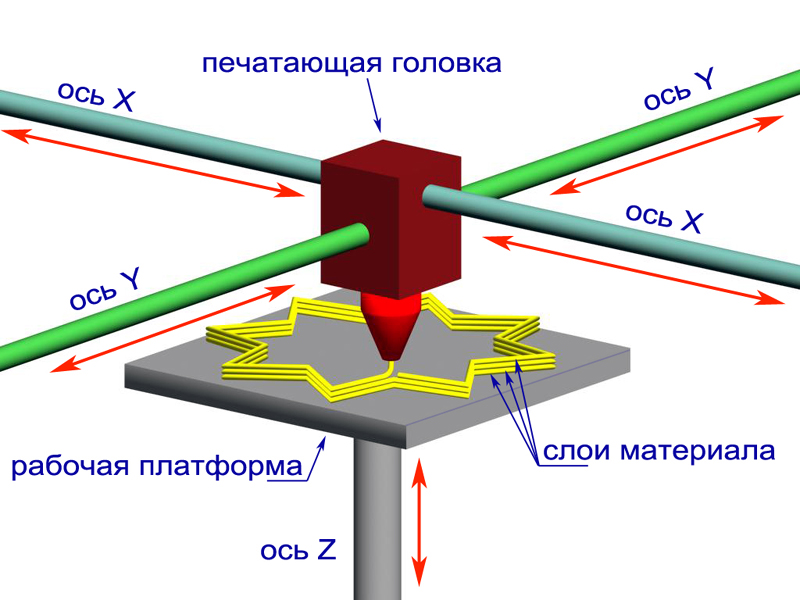

A 3D printer, in simple terms, is a device that creates three-dimensional objects by layer-by-layer printing. First, a model is formed in a special program, then it is processed using the so-called G-code generator - it is divided into horizontal layers and converted into a digital code. The latter becomes a command for the printer where and how to apply the material.

It is a complex structure in which the print head moves only horizontally. As a result of applying the material in several planes at once, a three-dimensional figure is created.The figure is formed on a special work table, which ensures gluing of the polymer and its fixation.

When applying one layer, the table surface is lowered one level lower - exactly the thickness of 1 layer and the print head applies the next layer until the object is completely created.

IMPORTANT! Nowadays, 3D printing has found application in all areas of human activity: from construction to medicine.

SLA technology

To understand, you should consider several possible options for applying a polymer material to form a product. One such way is to use SLA technology:

- A polymer or resin is poured into the container, which hardens when exposed to a laser beam.

- After turning on the system, the laser begins to move along the carriages.

- In certain places where the laser touches the polymer becomes harder, its structure changes.

- After passing through the layer, the container falls lower, forming a frame.

IMPORTANT! This produces clear parts with high strength and material quality, but using this technology is too expensive.

SLS technology

This method is based on the use of a laser beam to create a part layer by layer. A roller with a platform is installed in the center of the equipment. A special polymer material is supplied from it to form the workpiece. After applying a thin layer, the laser evenly glues sections of the polymer together, forming one level. This goes through several cycles until the finished form appears.

This option is somewhat more difficult to implement, but is not inferior in accuracy. The cost is on average lower compared to other versions.

DLP technology

The DLP printing option is a relatively new invention in the field of 3D modeling, but the principle is practically no different from the methods presented above. It is worth understanding that in DLP printing the main tool is a strip with LEDs attached to it instead of a laser unit, as with SLA technology. This allows you not only to speed up the process, get excellent quality, but also save on equipment. The presented version is an improved version and occupies a leading position.

EBM technology

Another option used in the field of 3D printing is the development of EBM. The technology involves the use of directed beams from emitters (electron guns). Due to the high temperature obtained when heated by a stream of rays, the material begins to melt, and subsequently allows the formation of a product of various configurations and sizes. Temperatures can reach up to 1000°C, which allows you to work even with some metals.

IMPORTANT! The main advantage of this method is high speed and high productivity, which is extremely useful at high rates of work and large scale production.

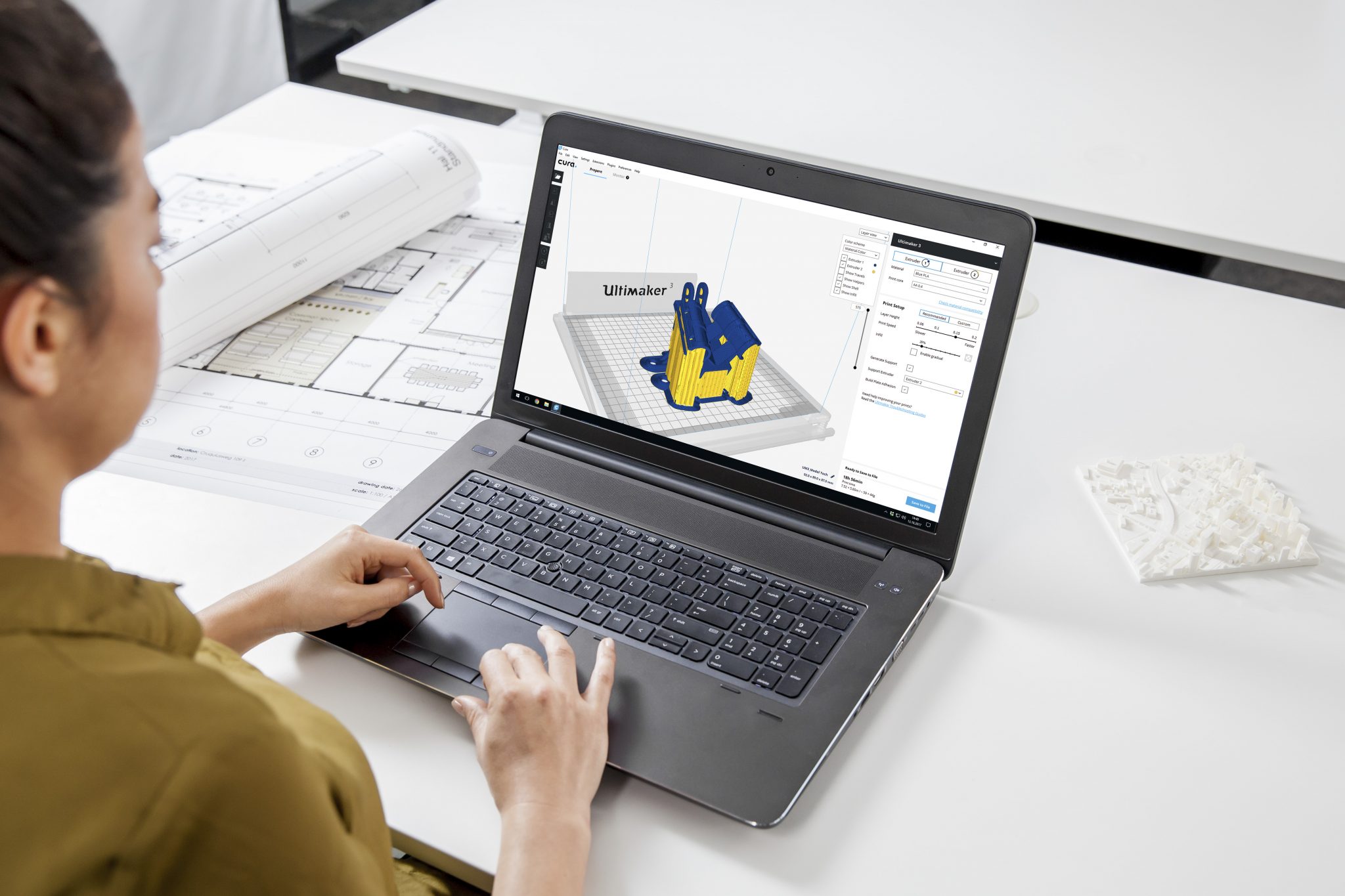

Controlling the 3D printer

To ensure the interaction of all systems, it is necessary to correctly manage the printing parameters and configure the equipment. There are various programs and applications to regulate the operation of a 3D printer. The main way is to use the settings of the software installed on the computer. With it you can adjust the following parameters:

- The temperature of the nozzle from which the polymer material is supplied to make the model.

- Temperature of the working table for better adhesion of the material to the surface.

- Speed and intensity of polymer supply to the working surface. This parameter also improves the application of layers.

- The operation of electric motors to move the printing press.

There are also special programs that use coding to interact with controllers and manage the workflow.

How models are created for 3D printing

To ensure such a complex process, it is necessary to use special models on which the future product will be built. If you are just starting to master technology, it is worth learning how to use standard programs and applications. Typically, the kit includes an installation disk with basic equipment and a set of ready-made figures.

You can find an application on the Internet or create a figure online. In this section, you need to complete the training to understand the basic procedure. After this, you can try to create your own layout of the future part yourself. The program itself will convert the file format and send it for printing.