DIY filament for 3D printer

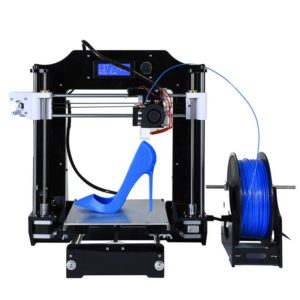

Advanced developments and the use of modern technologies have allowed manufacturers to create a printer that provides volumetric printing of various elements. This technology appeared relatively recently, but it could find application in many areas of human activity: in large enterprises, in science, medicine...

Advanced developments and the use of modern technologies have allowed manufacturers to create a printer that provides volumetric printing of various elements. This technology appeared relatively recently, but it could find application in many areas of human activity: in large enterprises, in science, medicine...

The operating principle is similar to that of conventional printer models. After connecting to a computer and installing the software, the operation of all systems is configured, then using ready-made shape layouts, a part is created, which is subsequently sent for printing. One of the few and most important differences is that the work is performed not on a plane, but in volume.

To ensure the normal functioning of the equipment, it is necessary to use special materials to create three-dimensional figures in space. Modern devices use a special polymer material, which we will talk about in our article.

The content of the article

Filament for a 3D printer - what is it?

To create any part, a manufacturing material is required. Through the interaction of complex processes, the polymer is fed into the channel, heated, and then applied layer by layer to the working surface of the printer’s thermal bed.

Filament in English means thread or thread-like strip. This most accurately reflects the main type of material exiting the nozzle.Various types of plastic can be used as a special polymer, each with its own advantages and disadvantages. For work, you should carefully select the material used in accordance with the requirements for the resulting parts when printing.

However, using original elements has a number of disadvantages:

However, using original elements has a number of disadvantages:

- Difficulty in ordering and delivering components for work.

- High cost of purchased materials.

- Difficulty in selecting for the specific task being performed.

Important! These disadvantages make working with a 3D printer difficult and very expensive, so many users are looking for ways to create filament themselves.

However, it is worth understanding that the use of non-native elements can lead to malfunctions and failures in the system that provides the workflow.

Is it possible to make filament with your own hands?

Fortunately, for most 3D printer owners, there are special devices for creating filament at home. These devices are called extruders. Currently, this equipment can be found on special websites on the Internet. Manufacturers offer a choice of three possible configuration options. Depending on the cost, the set of features will differ.

The work of creating material at home consists of several stages. If you decide to purchase this device, please use the instructions for use:

The work of creating material at home consists of several stages. If you decide to purchase this device, please use the instructions for use:

- Turn on the purchased equipment, make the necessary settings for high-quality work.

- Buy raw materials to create threads.

- Load the raw materials into the required compartment. If desired, several types of plastic can be mixed to obtain different properties.

- Adjust the feed speed and heating temperature.

- Wait until the plastic passes completely through the device to form a full coil.