Features of delta printers

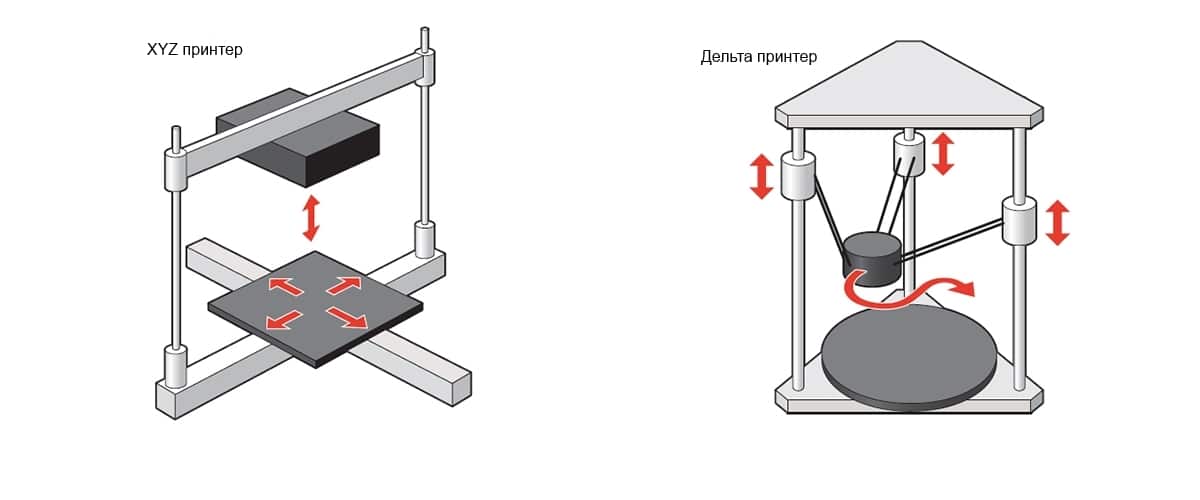

Many have heard about the now familiar 3D printers that work using the Descartes coordinate system. The print head in such devices moves along three axes (X, Y and Z). However, recently new so-called delta 3D printers have begun to be developed on the market, using an innovative system of extruder movements. The print head in such designs is suspended on thin levers, with each lever attached to one of three vertically located guides.

Many have heard about the now familiar 3D printers that work using the Descartes coordinate system. The print head in such devices moves along three axes (X, Y and Z). However, recently new so-called delta 3D printers have begun to be developed on the market, using an innovative system of extruder movements. The print head in such designs is suspended on thin levers, with each lever attached to one of three vertically located guides.

The content of the article

What is a delta 3D printer, its features

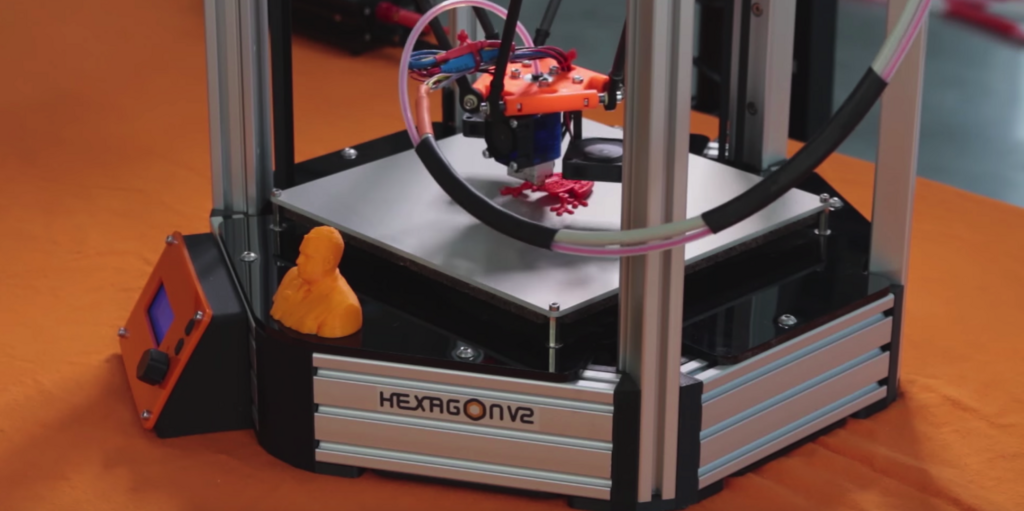

Delta printers have the ability to print more structured and taller shapes. Their design is not overly complex. Matt Walters, an amateur engineer and inventor who designed and built a delta printer called Thingystock, assures that most of the spare parts for the device he created can be constructed even in “makeshift” conditions.

The aforementioned Thingystock is equipped with an E3D V6 extruder. The volume of possible “dimensions” of printed products is 150x150x150. The operation is controlled by the integrated RAMPS 1.4 processor. The LCD screen is used to correct operation and settings. The approximate accuracy of the printing produced is about one hundred and fifty microns.The total price of the device with replaceable belt pulleys, extruder mounting parts and guides is no more than $550, which is actually a record figure for a 3D model.

Those who are thinking about purchasing a 3D printer for their own use should decide what result they want to get from the device. Models with Cartesian kinematics are usually delivered to the customer in finished form, and the printing process on them can begin virtually immediately after unpacking.

REFERENCE! Models with Cartesian kinematics are the most common, and it will be easy to find thematic online communities and forums on them on the Internet, which will indirectly facilitate their operation.

As for delta printers, they are supplied in the form of prefabricated kits with instructions for them. Sometimes it is quite difficult to find information about the nuances of working with such models, since they are currently less popular.

Pros and cons of the delta printer

Among the most relevant advantages of delta printers, experts highlight:

- relatively low price for the device when compared with “Cartesian” models;

- high speed of printing materials due to rapid movement of the head;

- almost complete absence of noise during operation;

- more convenient design parameters for printing vertical objects;

- low probability of distortion during printing due to the compact platform;

- compactness.

As for the main disadvantages of the so-called delta bots, they include:

- High demands on product detail, with the necessary size matching up to one hundredth of a millimeter.

- The need to work mainly on 32-bit processors.

- High complexity of retract adjustment.In the case of installing lightweight direct extruders like Titan, the mass of the effector increases and, as a result, the printing speed parameters decrease. In addition, the installation of such extruders increases the cost of the device itself.

- Possible difficulties with calibration, which on more expensive systems are solved by installing auto-calibration systems.

REFERENCE! Experts recommend that those who decide to independently assemble a “delta” at home rely on ready-made working solutions, otherwise problems with calibration and adjustment will be unavoidable, which will increase the assembly time.

The best delta 3D printer models

Below are the best printer models in this category and their distinguishing characteristics.

Mass Portal D300

The model has the largest construction area in the series, and uses high-temperature materials for operation. It operates at temperatures reaching 475 degrees Celsius and has a water cooling system for the extruder. Equipped with a chamber with a volume of 300x300x300 mm and an average head movement speed of 250 mm/sec.

3DQuality Prism Pro Dual

Specialized delta printer with automatic calibration and desktop heating system. The closed type of the camera of the device allows you not to worry about deformation of the printed product during the creation process. The working chamber has a diameter of 400 and a height of 860 mm. The head movement speed is slightly lower than that of the previous model, and is only 200 mm/sec. The device has two print heads and can be controlled remotely.

Delta WASP 2040 Clay

An indispensable model for those manufacturers who work with 3D ceramics.Support for all types of ceramic materials, speed and accuracy, openness and compactness of this model make it one of the best in its segment. The head movement speed is about 150 mm/s. The volume of the working chamber is not too large: about 400 mm in height and 200 mm in diameter.

As a conclusion, it is worth noting that the production technologies of modern delta printers have been significantly modernized over the past few years. This made it possible to improve their functionality and ease of use.

These types of printers find application in the following areas:

- architecture;

- art;

- industry;

- private use.

Despite the visible advantages, delta devices still require certain knowledge and skills to operate, and when choosing them, special attention should be paid to the control board capacity parameter and the presence of an auto-calibration function.