What is a 3D printer

One of the most promising trends in the modern world is the creation of three-dimensional objects using 3D printing. Printing technology allows you to create quite complex and detailed products. Today, the use of 3D printing is possible not only at production sites, but also at home; to do this, it is enough to purchase a 3D printer.

One of the most promising trends in the modern world is the creation of three-dimensional objects using 3D printing. Printing technology allows you to create quite complex and detailed products. Today, the use of 3D printing is possible not only at production sites, but also at home; to do this, it is enough to purchase a 3D printer.

The content of the article

What is a 3D printer?

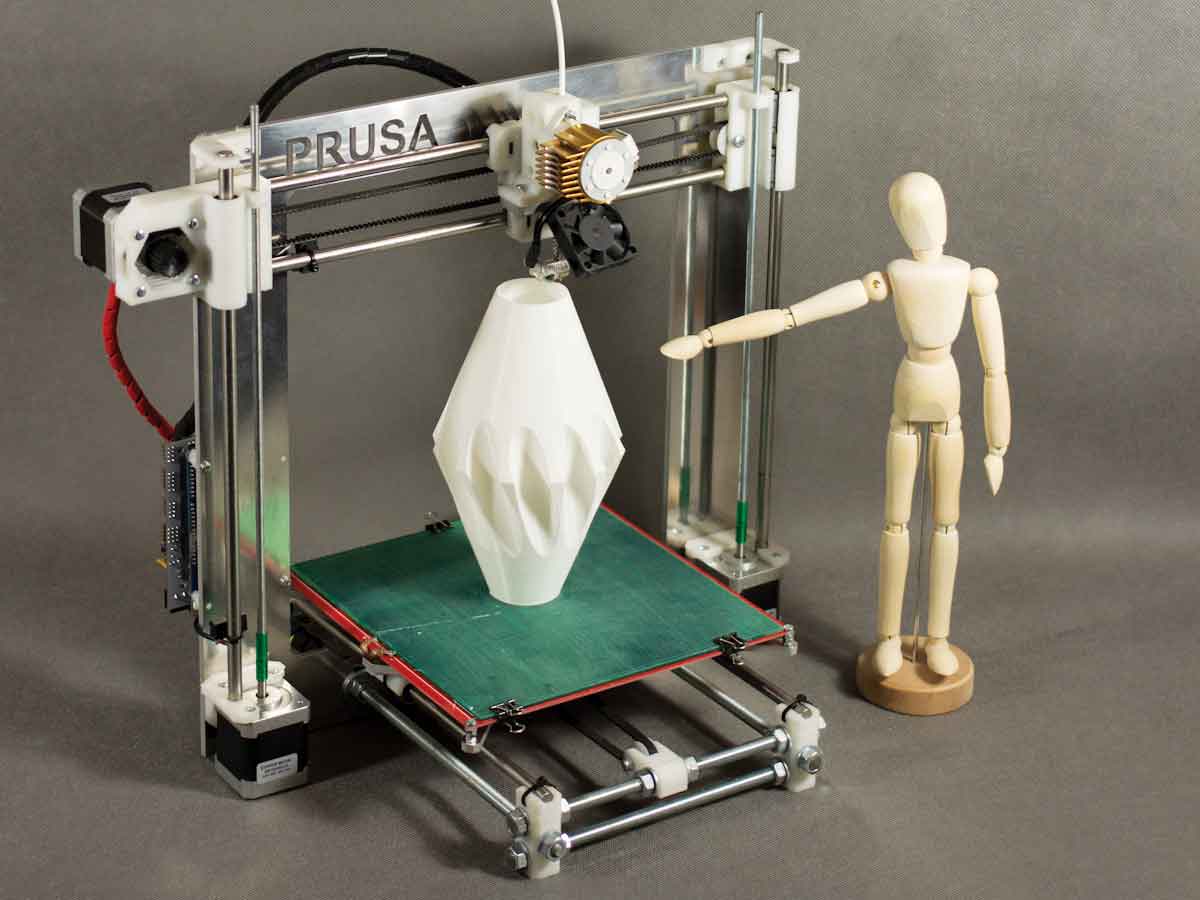

A three-dimensional printer is a device capable of creating objects based on created digital 3D models. Products are obtained by layer-by-layer application of material. Thermoplastic and photopolymer resins are used as a base, but with the development of technology, the number of materials used as raw materials increases.

The manufacturing procedure looks like this:

- The process of creating a 3D model takes place, i.e. a visual image of the future product is developed while maintaining all proportions. The model is created using specialized software.

- After creating the model, you need to process the file. Processing consists of converting the file into a digital code that divides the entire model into many parallel layers. In this way, commands are generated for the 3D device, which distributes the material to create the object.

- The final stage is 3D printing of the product, i.e. the process of creating a product by layer-by-layer application of material.The process is performed using a print head (extruder), which moves along the 0Y and 0X axes, i.e. the material is fed only along the horizontal plane in accordance with the layer’s program code. To apply the next layer, the extruder moves along the vertical guide (along the 0Z axis) at a distance equal to the size of the layer. After which the next horizontal layer begins to be applied.

Reference: The printing process may differ depending on the manufacturing technology, but the general process of creating products consists of layer-by-layer application of the material.

Types of 3D printers

Devices are divided depending on the uniqueness of the printing process, i.e. on the technology used. The most common printing methods are FDM (Fused Deposition Modeling) and SLA (laser stereolithography).

Directional modeling technology is one of the first printing methods to emerge. Thermoplastic is used as a material for making objects in the form of wound knitting needles or threads on a spool. The printing method is as follows:

- The spool or filament is installed in the extruder. Under the influence of the heating device, the material begins to melt and flows through the channel onto the working surface.

- The extruder moves along specified coordinates in accordance with a digital code. Manufacturing occurs in layers relative to the horizontal plane.

- In the manufacture of complex products, two materials are used: main and auxiliary. The product is created using basic material. The auxiliary material is intended to create temporary supports, as well as to fill the hollow space of the product. BecauseThe printer is not capable of printing an object in the air without any reason.

Reference: The auxiliary material is subsequently removed using a special solvent, or is easily broken off.

Products made using FDM technology have good mechanical and chemical strength. Such properties are achieved through the use of industrial grade thermoplastic. This technology is also lightweight and suitable for use at home.

SLA technologies, or stereolithography, print products using liquid photopolymer resins that harden under the influence of an energy source in the form of a laser. Using this method, products have high accuracy (up to 15 microns). Objects are printed as follows:

- The working surface is lowered into a container with photopolymer liquid to the depth of one layer;

- The energy source (laser) cuts the shape of the object according to the given object coordinates;

- A polymerization process occurs as a result of which hardening occurs at the points of contact;

- The procedure is repeated for each layer until the object is produced;

- After production, the model is immersed in a container with a special solution to clean it from auxiliary elements;

- The final stage is ultraviolet irradiation in order to speed up the process of product formation.

Stereolithography is one of the most modern technologies, but requires expensive materials. There are also lesser known types of printing:

SlS (selective laser sintering) the principle of creating an object is to supply a thin layer of material in the form of a powder to the working area, which is sintered under the action of a laser.The main advantage of this method is the absence of the need to use auxiliary elements, but it requires additional heat treatment. Not intended for use in domestic conditions.

EBM (electron beam melting). The technology is similar to selective laser sintering, but the product is created in a vacuum and does not require additional heat treatment.

Three-dimensional printing includes a 3D pen. The principle of its operation is similar to FDM technology, but has a more miniature appearance and is used to create drawings with a three-dimensional effect.

What can a 3D printer do?

Today, 3D printing is used in almost all areas of life. There are examples of creating culinary dishes using 3D printing. Parts of any complexity are created for more complex structures in all industries. But the most relevant and necessary area is still medicine.

Several companies are developing organic simulants that can practically replace natural fabrics. 3D printing can also help in the field of joint replacement. The most common application of three-dimensional manufacturing is in dentistry. In addition to prosthetics, printers are used to make organ models. 3D printing capabilities are increasing and becoming more accessible every day.

Several companies are developing organic simulants that can practically replace natural fabrics. 3D printing can also help in the field of joint replacement. The most common application of three-dimensional manufacturing is in dentistry. In addition to prosthetics, printers are used to make organ models. 3D printing capabilities are increasing and becoming more accessible every day.

3D printers help not only people, but also animals. One of the famous cases is the creation of a shell for a turtle that was injured in a forest fire. Thus, the new shell saved the animal’s life, and there are many such cases. Another unique case is a prosthetic leg for an elephant. The uniqueness of the case lies in the fact that prosthetics for elephants are practically not made due to the large weight of the animal.

Modern printing technology allows you to create even an entire building. The construction of the small house (37 sq.m.) took the researchers only 24 hours and was half the cost of the conventional method.