What does a 3D printer print with?

If previously 3D printers (computer-controlled machines that create parts using an additive method) that print three-dimensional models were used only in production conditions, today almost anyone can purchase a device for personal use. Using them you can create almost everything: from small trinkets to weapons and even buildings.

If previously 3D printers (computer-controlled machines that create parts using an additive method) that print three-dimensional models were used only in production conditions, today almost anyone can purchase a device for personal use. Using them you can create almost everything: from small trinkets to weapons and even buildings.

The content of the article

3D printing technologies

Additive printing technology was developed in the 80s of the last century. 3D printers became widespread at the beginning of the 21st century.

The operating principle of machines for printing three-dimensional parts can be divided into 3 stages:

- creating a model in the program;

- processing the model using software;

- formation (printing) of an object by layering material.

There are several additive printing technologies, including:

- Fused Deposition Method (FDM). Models are created by laying molten threads of wax, metal or plastic in a certain order.

- Stereolithography (SLA). A liquid polymer is used as the basis for the object, which hardens under the influence of laser radiation.

- Selective laser fusion (SLM).A technology in which metal parts of components and assemblies are created from metal chips according to mathematical models.

- Digital LED printing (DLP). The technology involves the use of liquid plastic, which hardens under the influence of ultraviolet light.

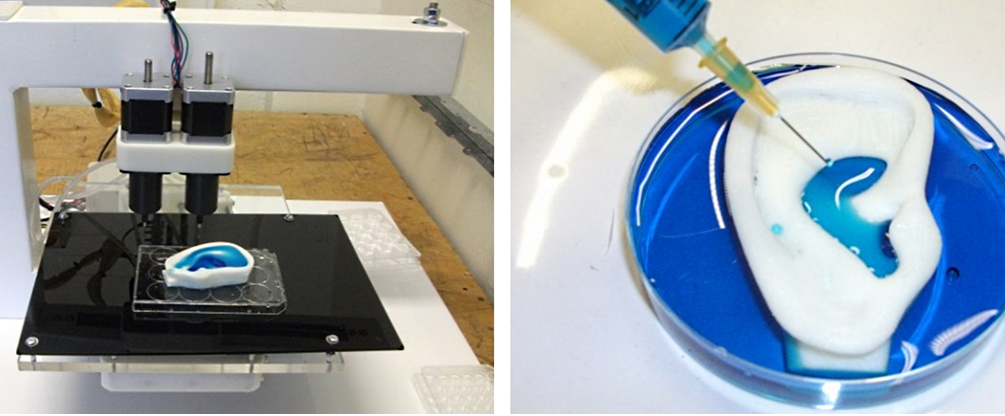

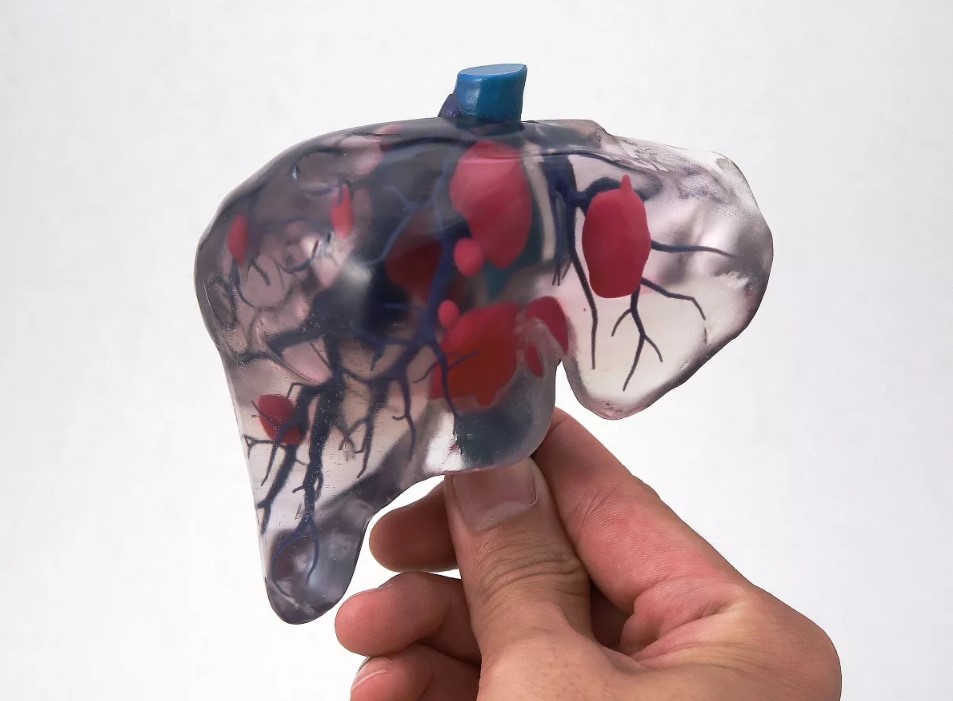

REFERENCE! One of the latest developments by scientists is bioprinters, whose printing technology involves the creation of organs and tissues. Objects are created by connecting droplets containing living cells, which must then begin to divide, grow and modify.

What does a 3D printer print with?

Depending on the area of application and purpose of the device, various materials can be used to create three-dimensional models.

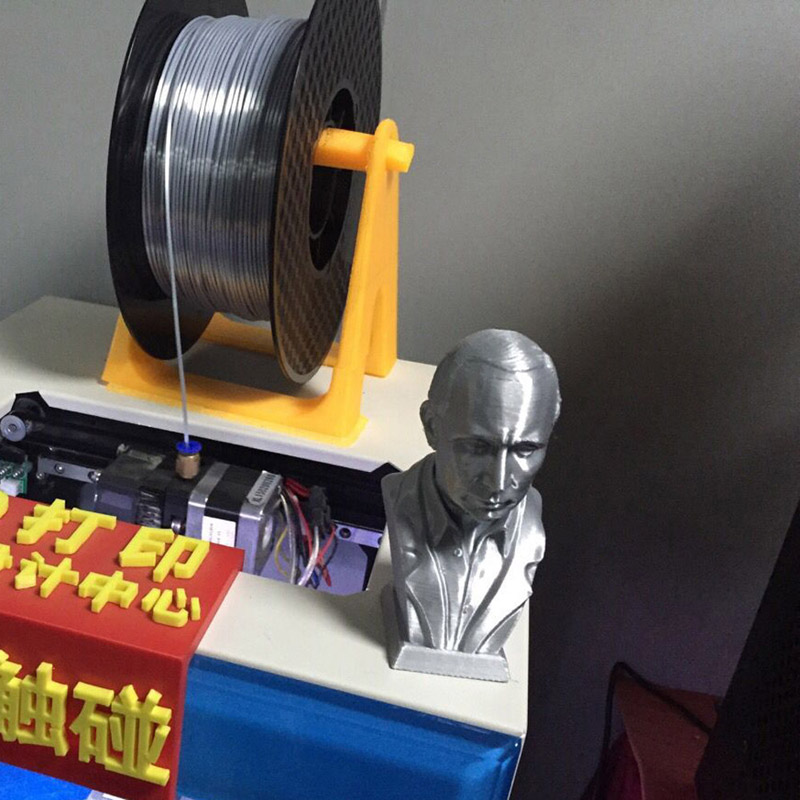

ABC plastic

The scientific name of the plastic is acrylonitrile butadiene styrene. It is one of the best consumables for volumetric modeling, as it has a lot of positive qualities - impact resistance, elasticity and wear resistance. In addition, ABC plastic is non-toxic and odorless. You can purchase the material in the form of spools of thin threads.

IMPORTANT! Only one-color, dense models can be created from ABC plastic. Products will be durable and will not lose their appearance and quality if stored away from direct sunlight.

Acrylic

Unlike ABC plastic, acrylic can be used to print transparent models. Its melting point exceeds 240 degrees Celsius, which must be taken into account, since acrylic hardens very quickly when cooling.

IMPORTANT! Air bubbles formed in the acrylic can spoil the appearance of the finished product.

Concrete

For printing on additive machines, new types of concrete are used, which are almost identical to stone building materials. To date, only test samples have been created. Huge devices can print a small house in less than a day.

Paper

Paper models printed on 3D printers are most often used to create prototypes of computer projects. The models themselves are not durable or attractive in appearance, but they are created at record speed. Devices that use paper as a consumable material create models by gluing one layer onto another.

IMPORTANT! Paper is one of the most accessible and widespread materials for modeling at home.

Hydrogel

The soft material, biocompatible with living tissues, is used in 3D modeling to create various transport devices that can deliver drugs deep into the human body.

Thus, scientists from the USA created robots whose height did not exceed 1 cm. Cardiac tissue cells were placed on their surface, which, when contracted, set them in motion. It is planned that such robots in the future will be able to participate in the diagnosis and treatment of many diseases of varying severity.

Gypsum

Gypsum materials in 3D printing are as widespread as paper, acrylic or plastic. Models made from them are not particularly durable, but the affordable cost completely covers this circumstance. Gypsum products are used to design presentation projects.

Wood fiber

Wood fiber is an innovative material. The idea of the creation belongs to the famous inventor Kai Party.The fiber, consisting of synthetics and natural wood, has properties similar to polylactide. Products made from it are similar to things made from natural oak or birch, but unlike them they are much stronger and more durable.

IMPORTANT! Today, wood fiber is used only in RepRap printers.

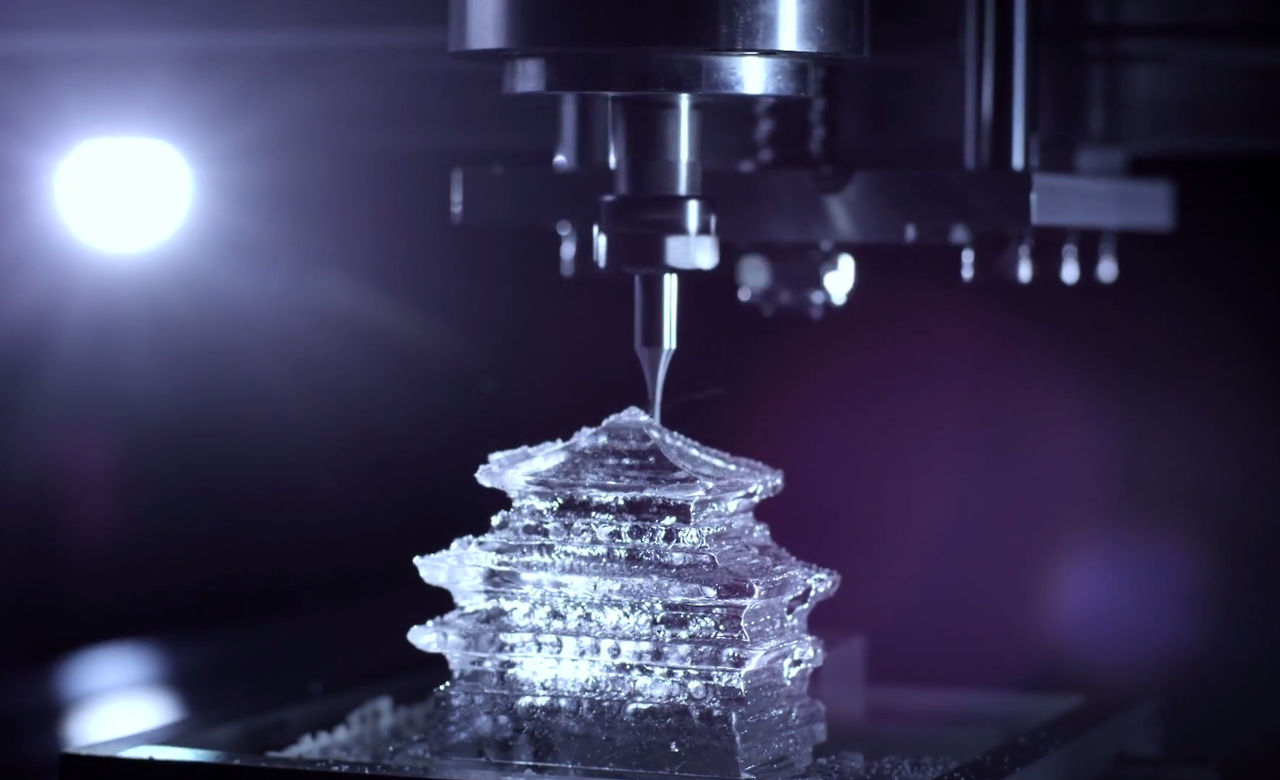

Ice

Ice figures of extraordinary beauty can also be created on 3D printers. Since 2006, thanks to the developments of two Canadian scientists, it has become clear that not only acrylic and paper can be used as consumables for 3D printing. A mixture of water and methyl ether at temperatures below 22 degrees turns into small objects, which, of course, are not particularly durable and strong.

Metal powder

Thanks to the use of metal powder, it has become possible to create products that are highly durable - parts and spare parts for equipment and electronics, and even jewelry are printed from light precious metals and their alloys, such as copper, aluminum, gold and silver.

IMPORTANT! Products made from such powder themselves have high thermal conductivity. To neutralize it, ceramic chips are added to it.

Nylon

Nylon is often used in three-dimensional modeling, since parts created with its help are soft and elastic.

IMPORTANT! Nylon has many disadvantages, including toxicity.

Polycaprolactone

Polycaprolactone is considered one of the most popular consumables for additive modeling. It melts well under the influence of sub-zero temperatures, hardens quickly, is biodegradable and absolutely harmless.

Polycarbonate (PC)

Polycarbonate is a plastic that can retain its characteristics and properties under the influence of different temperatures. Used to create heavy-duty models.

Polylactide (PLA)

Polylactide is recognized as the safest and most environmentally friendly material. It is created from beet and corn silage and biomass. Among the disadvantages of polylactide are its fragility and ability to decompose under the influence of heat and light.

Polypropylene (PP)

Polypropylene is recognized as the lightest plastic mass known to the world. It resists abrasion well, but melts less well. Changes shape in the cold and is unstable to oxygen.

Polyphenylsulfone (PPSU)

Resembling ordinary glass in appearance, polyphenylsulfone is many times stronger than polypropylene. It came to 3D modeling from the aircraft industry and was recognized as the best material for creating products with high heat resistance and hardness.

Low Density Polyethylene (HDPE)

Polyethylene is found in everyday life at almost every step. It is used to make plastic containers for drinks, packaging films and containers, PVC pipes, etc. It is a leader in 3D printing, as it can be used in any of the known technologies.

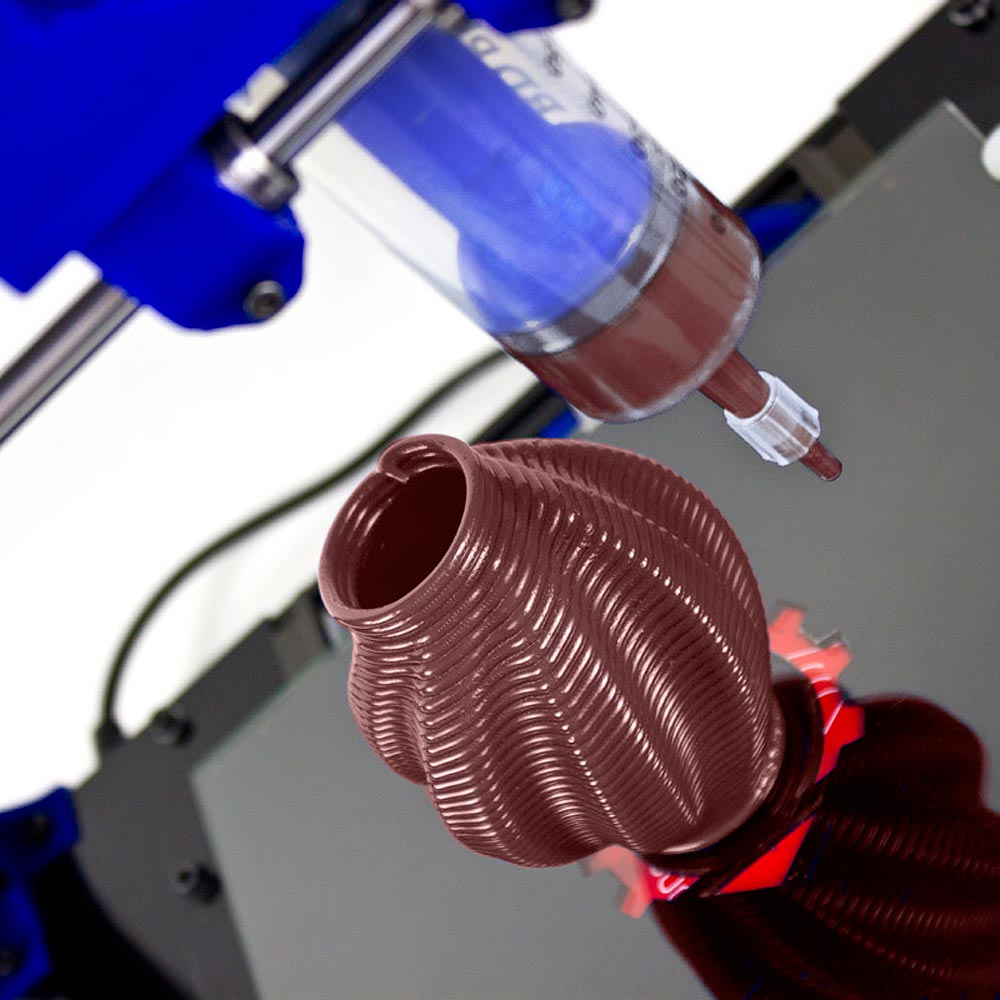

Chocolate

3D printers “powered by chocolate” will soon become a must-have attribute of every confectionery shop. With their help, you can create figures from sweet material of any complexity. The technology for their creation consists of sequentially layering one layer of chocolate on top of another, which quickly hardens in the cold.

Other materials

There is a huge selection of 3D printers in the world that use the most unexpected consumables.These include devices that run on lime, food, and even living organic matter. Whether they will gain widespread popularity and become in demand, only time will tell.