4d printer

Despite the fact that 3D printing is still considered a new technology, developers from Harvard University have proven that progress is rapidly developing. A team of scientists took a 3D printer as a basis and added a fourth dimension.

The content of the article

4D printer: what is it

By “4D printer” we mean not using 3 dimensions (X, Y, Z) to print real objects, but also using the fourth dimension – time (T).

If you add special materials to printed objects that can respond to external factors - for example, cold, water - then these objects can move and change shape over time, like human muscles.

How does a 4D printer work?

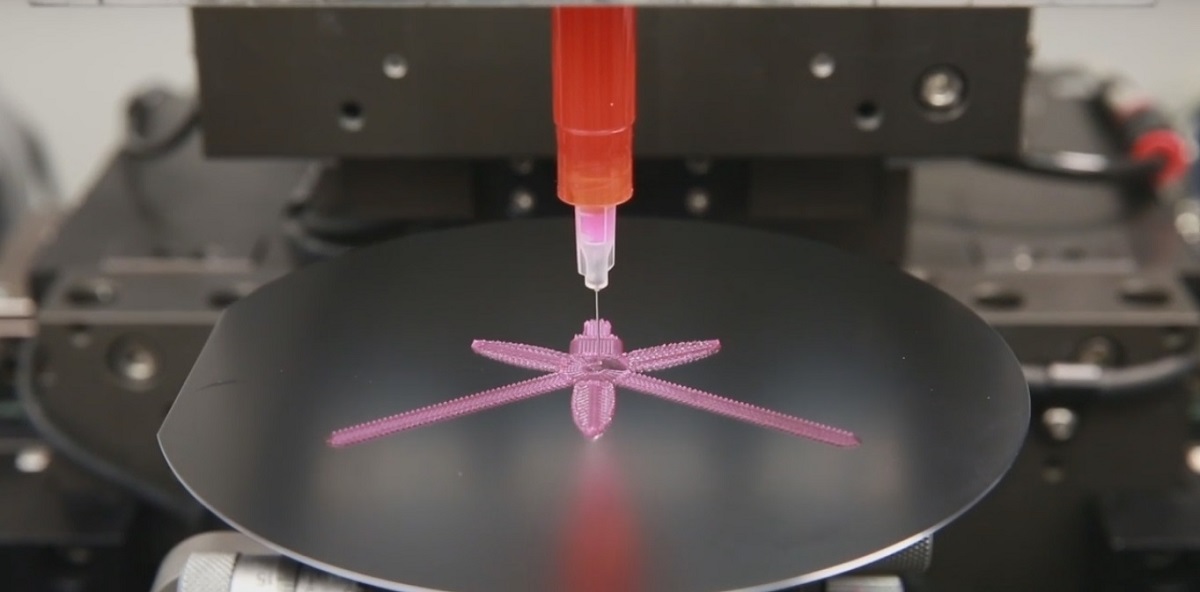

4D printing is the latest technology based on 3D printing. The improvement consists of adding an intermediate layer of “smart” material during printing that is capable of absorbing moisture.

In this case, moisture is a source of energy for increasing the volume of the material after printing on a 3D printer. The main object is first processed by the printer, and then with the help of water it changes and receives the required shape.

Reference! These innovations make it possible to print any item in a fairly short time. It is “Time” that is the 4th dimension.

What can be printed on a 4D printer

The Harvard laboratory has printed many different objects that are capable of taking the desired shape or self-assembling. Scientists have demonstrated self-tying shoelaces and self-unfolding furniture. The new technology is also used for other purposes.

Protection of space satellites

Using a 4D printer, NASA scientists have made a special metal fabric that protects satellites from damage and is also needed to make elastic antennas.

This is a kind of “chain mail” made of silver with the addition of some other metals. The fabric can be compressed, stretched and folded. Despite its elasticity, the material is very difficult to tear. It is planned that in the future satellites will be wrapped with this fabric before entering orbit, or spacesuits and space stations will be shielded using the material.

Military technology

4D printing will be used in the chemical field and in the study of materials science for the defense industry. A 4D printer allows you to print new biochemical sensors, materials and components for chips.

Reference! Currently, progress is hampered by the lack of inexpensive devices that can produce high-resolution prints of objects (approximately 1000 times thinner than a human hair).

Use in medicine

Surgeons from Shaanxi (China) successfully performed a complex tracheal operation using 4D printing technology. They installed a tracheal stent in the patient, which allowed him to keep his respiratory organs open. To manufacture the stent, the biological material polycaprolactone was used, which dissolves over time - degradation in the human body occurs within three years.Surgeons have previously calculated the dissolution time of the printed stent, and the patient will not need to undergo a special removal operation.

An approximately similar incident occurred in America. Garrett Peterson was born with bronchomalacia, a condition where the joints are very soft.

It is quite possible that new biomaterials printed on a 4D printer will very soon go far beyond the pathologies of the respiratory system. Research is already being carried out in terms of facial restoration.

In general, many scientists who work in the field of 4D printing predict the rapid growth of objects and biomaterials using the modern printing method within 5-6 years