Laminator, what is it?

The laminator was used exclusively by printing houses. Today, each of us can purchase equipment. Laminator - designed for quickly covering important documents with a protective plastic film.

The film (polyester or polyvinyl chloride) protects the paper from aggressive environmental influences and gives the document a neat appearance. Depending on the type of polymer film, the surface of the paper can be matte or glossy.

The content of the article

Laminator types

Purchasing a laminating machine is not difficult. There are models that can be used at home. First retro - laminators appeared in the 80s, invented by engineers from the GSM Corporation. The models were presented in the form of massive roll laminators of the first generation. After 6 years, GSM released second-generation devices based on touch-electronic control. batch laminators.

Roll models for lamination. Roll film is used as a consumable material, characterized by the following parameters:

- thickness (24–250 µm);

- width (305–1000 mm);

- d bushings (25, 48, 76);

- length (50–500 m).

High product quality is achieved due to heating rollers. During operation, foil stamping is carried out. R/L take up a lot of space and are used in printing houses, copy shops, etc. where large volumes of documents need to be laminated.They are characterized by high productivity, which allows them to produce huge quantities of products.

Depending on the model, double-sided lamination is possible. The price of film material is low.

Batch models for lamination. Widely used at home, in small offices and salons. Documents are accepted in medium volumes. For work I use two sheets of adhesive-based polymer film, one side of the consumable is sealed. Film characteristics: format (A4 and above) and width (60–250 microns). The cost of this type of laminator depends on the amount of paper format.

Batch models for lamination. Widely used at home, in small offices and salons. Documents are accepted in medium volumes. For work I use two sheets of adhesive-based polymer film, one side of the consumable is sealed. Film characteristics: format (A4 and above) and width (60–250 microns). The cost of this type of laminator depends on the amount of paper format.

Heating tools are hot plates or rolls with external heating, which do not allow regular use of the laminating machine. The advantage of the models is ease of use and affordable price.

The principle of operation of the laminator and its application

There are hot (g/l) and cold lamination (c/l).

Hot lamination involves heating consumables and products up to 70 degrees. This heats up the adhesive layer, causing the two components to bond.

This method has a number of advantages:

- ease of manufacture,

- reliable and high tightness of the product.

REFERENCE! Currently, the use of hot lamination prevails over cold lamination.

Cold lamination method used in cases where heating two elements can be detrimental to the material. The method involves passing the film and product under a press. The principle is based on the effect of high pressure on a high-strength adhesive base, which subsequently softens and adheres to the surface.

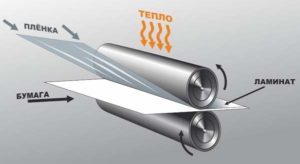

When batch lamination is used, a ready-made package of two films is used, soldered along one short side. The paper to be used is placed in a sealed bag and passed through a laminator between two rotating hot rollers. Pressure and heating by the rollers allow the film to evenly straighten and sinter together along the edges of the paper. The result is hermetically sealed paper.

Roll lamination is carried out using the laminator itself and consumables in the form of a film of various widths and lengths. As a result, the film is supplied from two (double-sided lamination) or one (one-sided lamination) rolls. Also, material (paper) or flat sheet blanks are supplied from a roll. When passing between two pressure rollers, the film is firmly glued (x/l) or sintered with paper under high pressure (g/l).

Application of laminators

Laminating photos or documents has become an indispensable process in many offices, copy centers, gardens, institutions, mini-printing houses, printing houses. Lamination allows you to preserve the neat appearance of products for a long time. Roll laminators are mainly used for laminating large products: outdoor advertising, notice boards and others. Batch laminators are suitable for educational institutions, gardens and home use.

Advantages and disadvantages

When choosing one or another laminator for your office or home, you should start from their main advantages.

Roll laminators and their advantages:

- ability to laminate paper formats from A0 to A3;

- high productivity, large production runs;

- equipping with heating rollers allows you to achieve the highest quality products;

- possibility of using ultra-thin films starting from 8 microns;

- Consumables in rolls are cheaper.

There are slightly fewer negative sides:

- not all models support the function of single-sided and double-sided lamination;

- unusually complex equipment design;

- take up a lot of space;

- Working with models requires the assistance of highly qualified personnel.

Batch laminators and their advantages:

- greater availability;

- simple equipment design;

- support the function of single- and double-sided lamination;

- do not require supernatural skills when working with the device; professional level models

- have the function of regulating temperature conditions and process speed;

- laminate paper in A3-A6 formats.

Minuses:

- expensive consumables;

- low productivity;

- intended for occasional use;

- different models laminate certain formats;

- One-sided lamination exclusively in special bags.

Note! You need to choose a laminator depending on your needs.

Based on all this, you can choose a suitable laminating machine.