How does a laminator work?

The laminator has long become an indispensable device for both large printing houses and small institutions. The principle of its operation is simple and clear, but you need to know the basic rules for the operation of the device. Further in the article we will look at what this type of equipment consists of and what the principle of its operation is based on.

The content of the article

Design and principle of operation of laminators

The product consists of two shafts - a transit and a clamping design. The simplest modification is equipped with one pair of shafts that can advance the sheet and press it. Specialized and expensive modifications have up to 3 pairs, with enhanced pressure functions. The final appearance of the processed document will directly depend on what type of film is used.

Laminator and lamination

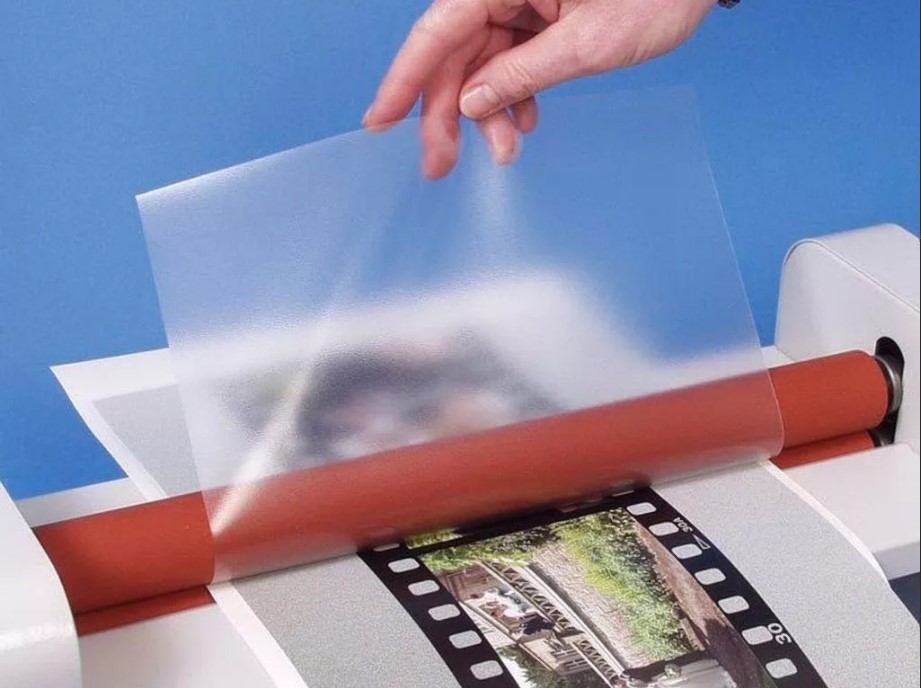

A laminator is a special device that instantly covers the surface with a layer of protective cellophane. He fuses two plastic sheets together with a piece of paper sandwiched between them. This process is called lamination.

It is also used to protect floors and other coatings from negative environmental factors.Lamination allows you to extend the life of documents and securities and improves their appearance.

Laminator design

In addition to the shafts, the design includes a reverse. This is a lever that allows you to start the engine in the opposite direction. In some cases, it allows you to save the situation by returning the layout of the sheet “one step back”.

Large-sized products are equipped with an auto-start pedal. It is convenient to use at the stage of film installation and initial testing. The worker can safely secure the paper base.

Attention! For comfortable use, many models are equipped with legs on which you can wind the cable, and convenient handles for transportation.

Types of laminators

There are several types of laminators, which differ in different characteristics.

Batch Laminators

Laminators of this type can be found in completely different institutions. These can be government organizations, large companies, printing workshops, educational studios, etc. They differ in configuration, material of manufacture, the presence of temperature and speed control functions, as well as the possibility of foil stamping.

Important! A film resembling an ordinary bag is used as consumables.

The pre-prepared material is placed in a bag and passed through a laminator. The shafts of the device constantly rotate and capture the film, heating its adhesive composition. Cellophane sticks and becomes completely invisible.

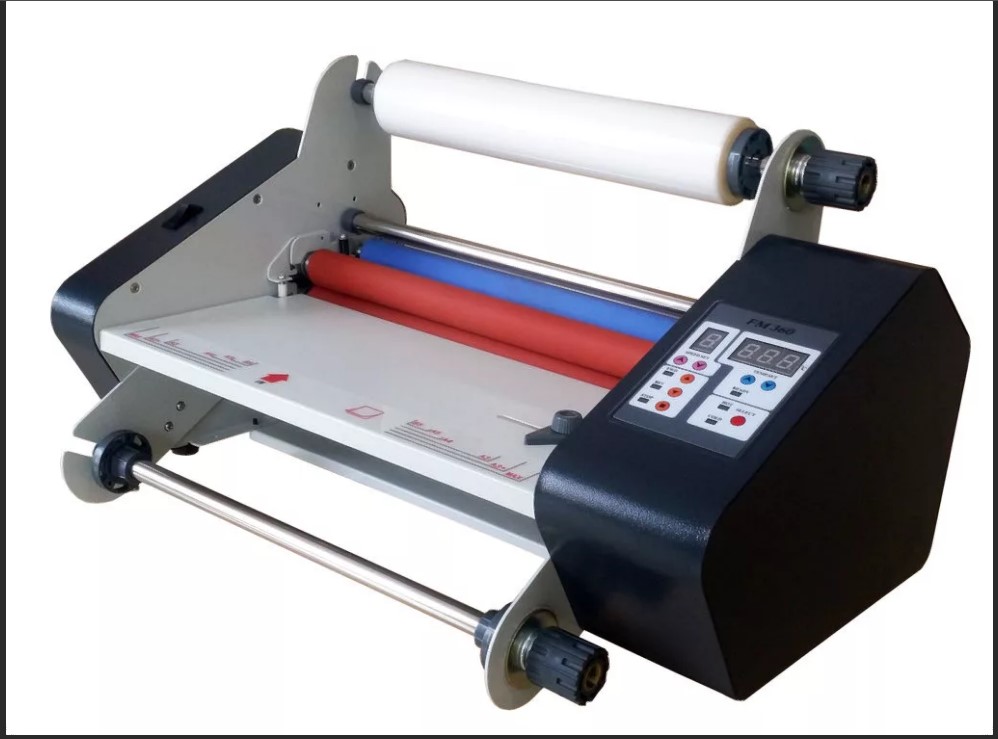

Rolled

Roll laminators are purchased for large-format printing and outdoor advertising production. They are bought for printing houses, offices and copy centers.

Unlike batch ones, in this case use film wound into a roll. It is fixed on a special element so that when the film is passed between the rollers, the adhesive side faces towards the sheet being laminated.

When choosing It is worth paying attention to the following characteristics:

- lamination strip width;

- speed indicators;

- possibility of one-way work;

- continuity of the process;

- ability to work with different thicknesses.

Shafts

Different rollers are used in the lamination process. They differ in the material of manufacture, brands and the possibility of applying a design. Let's look at their main types and how they work.

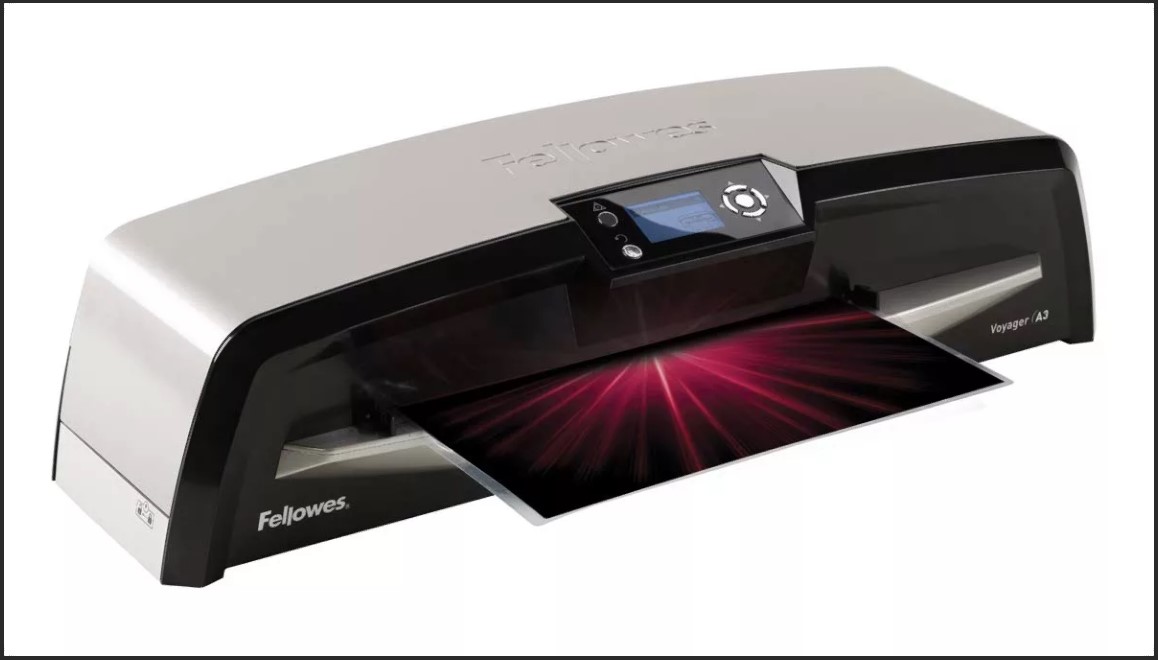

Liquid crystal display, programming, separate heating of shafts

In expensive models, liquid crystal displays are used to simplify operation. Such a well-thought-out system allows you to quickly enter data into the device and change settings.

You can enter frequently used characteristics into the device’s memory and set the desired operating mode. This will save significant time in the future. This is also convenient when performing complex tasks when different film thicknesses are used. In this case, it is necessary to set different temperatures in the upper and lower heating elements.

Roll heating system

There are devices with cold shafts that cannot heat up. They are used for rolling film over a workpiece. In this case, be sure to warm up the adhesive base using heating plates.

Hot roll laminators

This type of design has a built-in infrared heating device. Moreover, it is located directly inside the shaft. Therefore, during lamination, the film is simultaneously rolled and the glue is heated.

Using this technology, it is convenient to make photo cards and foil stamping.Heating can also be external, when the thermoelement is located near the shaft, but does not come into contact with it.

Reference! The positive aspect of using a laminator with hot rollers is the uniformity of heating.

"Shoe"

This half-shaft is used for preparatory heating of the adhesive base. This allows you to increase the speed of work several times. The “shoe” is also used as an individual heating part.

Heating levels

The device is equipped with a convenient step-type system that allows heating in stages. Due to this, productivity and efficiency are significantly increased. There can be three degrees of heating.

The following variations are popular: shaft-plate-shaft or shoe-shaft and others.

Important! The lamination speed increases according to the number of preliminary heating stages: the more there are, the more productive the work process. Of course, in this case, we should not forget about the diameter of the structure and the maximum possible temperature.

The choice of laminator depends on the volume of work.

Knowledge of the basic principles of operation of a laminator and its components will allow you to competently build a work process and prevent possible nuances. You can find devices of simple designs that allow you to use them even at home.