How batteries are made

In everyday life, we are surrounded by many devices that require a source of electricity to operate. Some of them use batteries as a power source.

Meanwhile, few people think about the question of what this small current source consists of and how it is made. And if such a question arises, then many disassemble the device and discover incomprehensible elements.

Let's study together the structure of the battery and find out where and how it is produced.

The content of the article

What are batteries made of?

There are four types of batteries. Despite the fact that their operating principle is the same, all current sources have a unique design and consist of different parts.

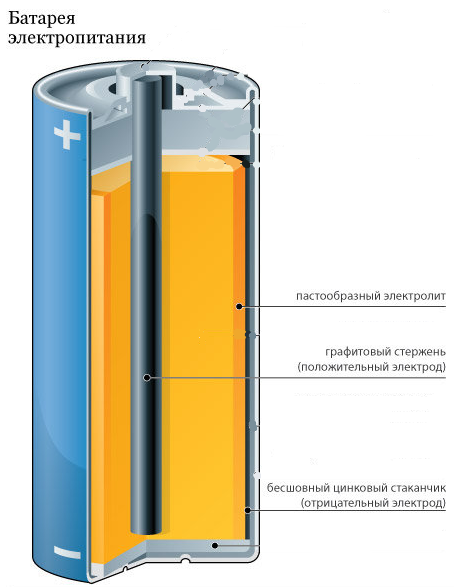

"Finger" and "pinky" batteries

“Finger” and “little finger” current sources are a small cylinder. These are one of the most common battery options. They consist of the following elements:

- negative charge - cathode;

- an insert that acts as a kind of gasket;

- housings;

- membranes;

- an electrolyte that ensures the normal course of a chemical reaction;

- a rod made from a carbonaceous compound, such as coal or soot;

- fixing washer;

- positive charge - anode.

This is the standard design for most cylindrical batteries. But there are devices consisting of a rod made of coal, metal parts and special powder.

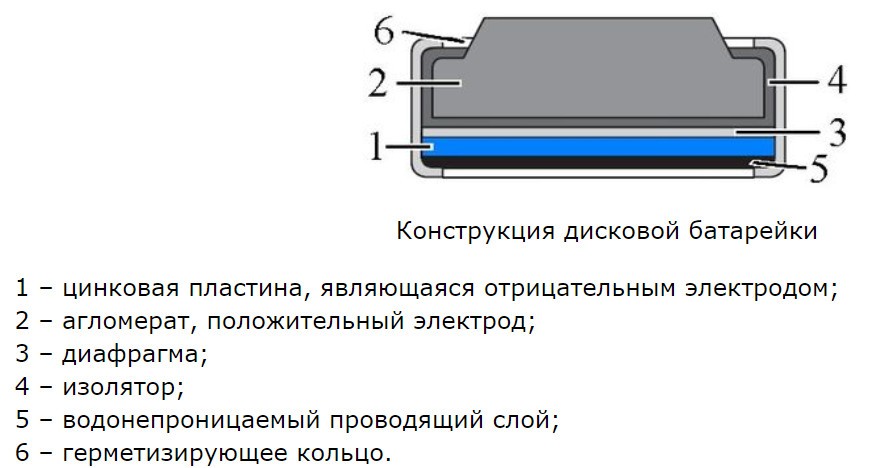

What does a coin cell battery consist of?

The battery, which has an unusual flattened shape, is also called a “tablet”. It is most often used in watches and various alarm systems. It consists of the following elements:

- anode - one of the covers plays its role;

- cathode - the second cover serves as the negative contact;

- gaskets additionally impregnated with electrolyte;

- mercury dioxide;

- zinc powder;

- waterproof layer;

- rings ensuring reliable sealing.

Reference. If you heat the “tablet”, it will simply explode.

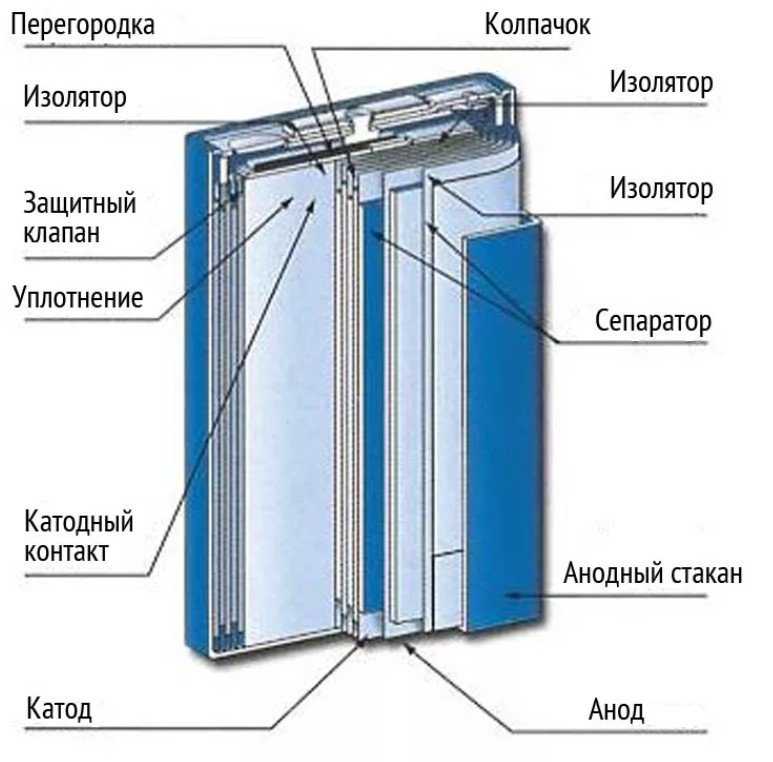

Cell phone battery

The design of a cell phone battery is somewhat more complex than that of conventional batteries. It includes:

- positive and negative contact;

- anode body;

- cathode glass;

- sealing agent;

- separator;

- insulating composition;

- protective membrane;

- diaphragm;

- housing made of aluminum or other metal.

What does the crown consist of?

The rectangular power supply is structurally different from other batteries. The positive and negative contacts are on top of each other. They are located at the top of the device. Below is a base made of plastic. A plate extends from the negative contact and is fixed to the negative pole.

The device body is made of metal.Inside it are six small flattened rectangles, each of which is an individual battery. The charge of such a “barrel” is 1.5 V. Between the plates there is another one - a special one.

The structure of the power supply is quite simple:

- two contacts - positive and negative;

- housing made of aluminum or other metal;

- two plastic plates;

- six interconnected “barrels” of 1.5 volts each;

- carbon compound rod;

- plates for insulating “barrels”;

- film;

- outer shell.

What is the battery housing made of?

The housing is one of the most important design elements of a current source. It performs a protective function by holding the contents of the battery inside and preventing its destruction.

Which power supplies have a body made of zinc?

Many people ask this question for good reason, because Zn can be used in a variety of experiments. Or just sell it. Thus, all salt batteries are equipped with a zinc body. Usually this is indicated directly on it.

Recently, it is increasingly possible to find current sources with a housing made of tin or iron. The material used depends on the internal configuration of the batteries. Iron and tin can provide maximum protection and increased strength.

What is the casing of cylindrical batteries made of?

It has a simple design, which includes:

- top and bottom parts;

- lateral oval part;

- marking indicating the type of current source.

Reference. Many people mistakenly refer to the housing as the compartment in which the batteries are placed.

Chemical composition of batteries

The chemical composition depends on the specific type of current source.Most batteries contain the following chemical compounds:

- iron;

- lead;

- manganese;

- aluminum;

- lithium;

- cadmium;

- mercury (lately they are trying not to use it).

Reference. It is worth keeping in mind that one battery cannot contain all chemical elements at once.

How batteries are made

Battery production is as follows:

- Oval-shaped plates are cut from steel.

- The prepared elements are rolled into a tube, which will later serve as the body of the device.

- All chemical elements are placed in the tube: graphite rod, electrolyte, zinc powder, thickener, catalyst and others.

- The next step is making the cathode. To do this, a special press “rolls” the necessary chemical compounds.

- A groove is applied to the capsule of the future battery. It is necessary to simplify the soldering process.

- Sealant and glue are applied to the negative pole, which dries while the device moves along the conveyor belt.

- An electrolyte is poured into the body, and a gel made of zinc is poured into the anode cavity. It gives the electrolyte a silver-gray tint.

- To charge the device, a 4 cm long nail is “welded” to its bottom.

- Next, the negative contact is soldered.

- In order for the device to take on its final form, all edges of the body are folded.

- The last stage is checking the functionality and applying the necessary markings.

Battery production equipment

To produce batteries, factories use various automated installations. The composition of the line may vary, but in most cases it includes:

- vibration machine;

- machine that makes the body;

- line dividing machine;

- assembly machine;

- assembly station;

- special "plate".

Which factories assemble batteries?

There are five factories in Russia that assemble batteries:

- "Space". He began his activities back in 1933. Its structure includes more than 35 production facilities located throughout Russia and in some other countries, for example, there are several factories in China. Every year the factory produces more than one hundred million current sources. During its existence, the manufacturer has proven itself from the best side, which is confirmed by numerous awards.

- "Photon". Despite the fact that the company appeared only in 2011, it has managed to take a leading position in the battery production sector. This is due to the high quality of the products. Numerous tests have confirmed the long service life of the batteries. At the same time, they cost much less than their imported counterparts.

- "Liotech". The plant is considered a joint brainchild of Russian and Chinese corporations. Its facilities assemble and produce lithium-ion power sources used for the production of batteries.

- "Energy". The enterprise, located in the city of Yelets, works closely with the Ministry of Defense. This confirms the reliability of the manufacturer and the high quality of the products. In 2011, the line was modernized and a conveyor for assembling lithium-ion power supplies was launched. The main part of the products are “finger” and “little finger” batteries.

- "SSK". The factory began producing batteries in 1993. Mostly fourth and fifth generation batteries come off the assembly line.In addition, the plant is continuously working to increase the battery capacity, and is also studying new materials for manufacturing.

Now you know what power supplies consist of and how they are produced. However, do not forget that each manufacturer uses its own developments, so the design of batteries and the composition of the line may differ significantly from the standard version.