Ceiling insulation in a private house

Many people, when building a private house on their own, do not want to spend time, money and effort on insulating the ceiling, relying on a stove or electric heaters. But in this situation, heating a room without top insulation will require more resources, which ultimately will become a less economical option. Therefore, we recommend that you take care of this issue, especially since this type of construction work is considered one of the simplest, even for non-professionals.

The content of the article

Where to insulate the ceiling: inside or outside

Both methods result in the same degree of thermal insulation, but the second is more convenient and versatile. Therefore, internal insulation is resorted to only when it is not possible to implement another, for example, if the roof of the attic is too low, important utilities are laid on it, or other owners live there.

By the way! If the room is ready for renovation, then it is more expedient to prefer the external method for economic reasons: you do not have to dismantle the ceiling.

Options for attic insulation

As the name suggests, when choosing an external method, work is carried out from the side of the attic, while when choosing an internal method, work is carried out from the side of the room. In the first case, any type of insulation can be used, since it is enough to spread it/scatter it onto the bottom layer and cover it. In the second, the insulating material is attached to the top, so options with bulk varieties are eliminated.

There is also an intermediate method - installing a panel ceiling. It sounds simple: first the panels are assembled, and then they are installed in place of the ceiling. But in practice, there are so many important details in this method that it is considered the most labor-intensive and feasible only with the help of professional builders.

Materials for thermal insulation

The main criteria for choosing a material include the method of insulation, climatic conditions (which determines the thickness and degree of thermal conductivity), the need for additional work, time spent and cost. Thermal insulation can be divided into four types:

- Board materials include: compacted mineral wool, cork plates, ecowool, extruded foam, etc.

- Rolled - mineral wool and foamed polyethylene.

- Bulk - expanded clay, ecowool, dry sawdust and other natural materials.

- Sprayed - polyurethane foam, penoizol, ecowool.

Important points are naturalness and absence of toxic emissions. From this position, the best options include cork, ecowool, linen mats, peat blocks, foam glass, expanded clay and sawdust.

Installation of different types of insulation for thermal insulation of the ceiling in the house

The most common option among non-professional builders is the use of slab and roll materials and bulk materials (due to the similarity of technology, we will combine them into one group). Sprayed ones are more difficult to work with and have many safety requirements, so professionals often resort to them.

Use of slab and roll insulation

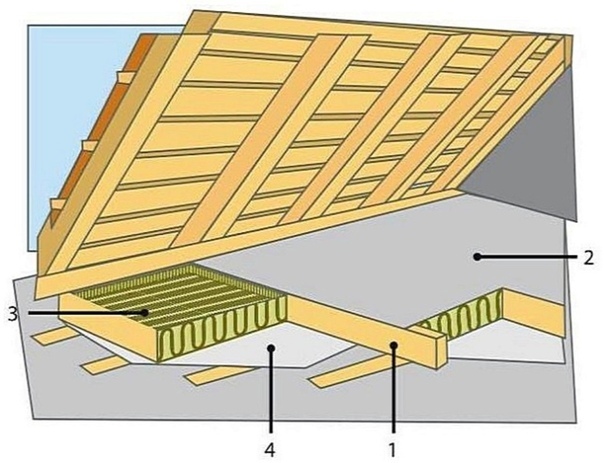

Their installation is carried out according to the following scheme:

Where 1 - floor beams, 2 - waterproof film, 3 - insulation and 4 - vapor barrier.

First of all, a vapor barrier membrane is laid, which is attached to the beams with a construction stapler. It is necessary in order to protect the thermal insulation and wood of the floor from water vapor that harms them.

If there is a foil layer on the vapor barrier, then it should be directed towards the room. If it is not there, then you should focus on the production marking. The film is overlapped, and the joints are fastened with reinforcing tape.

When working with polystyrene foam, the surface between the beams is first leveled, and the use of a vapor barrier is not necessary, since it itself has vapor barrier properties. Alignment is necessary for a tight joint with the base, since polystyrene foam, unlike cotton wool, is hard and does not fill uneven areas.

After installing the base, insulation is laid on top. If it is made of foam, then it is important to cut it to size as accurately as possible. But even with the most careful work, there are inevitably gaps that need to be foamed.

A waterproofing membrane is stretched over the insulation, which is attached to the beams with staples. The final step is laying the floor. However, if you don’t plan to use the attic, you can skip it.

Important! In order to prevent the occurrence of condensation, there must be a ventilation gap between the floor and the waterproofing.

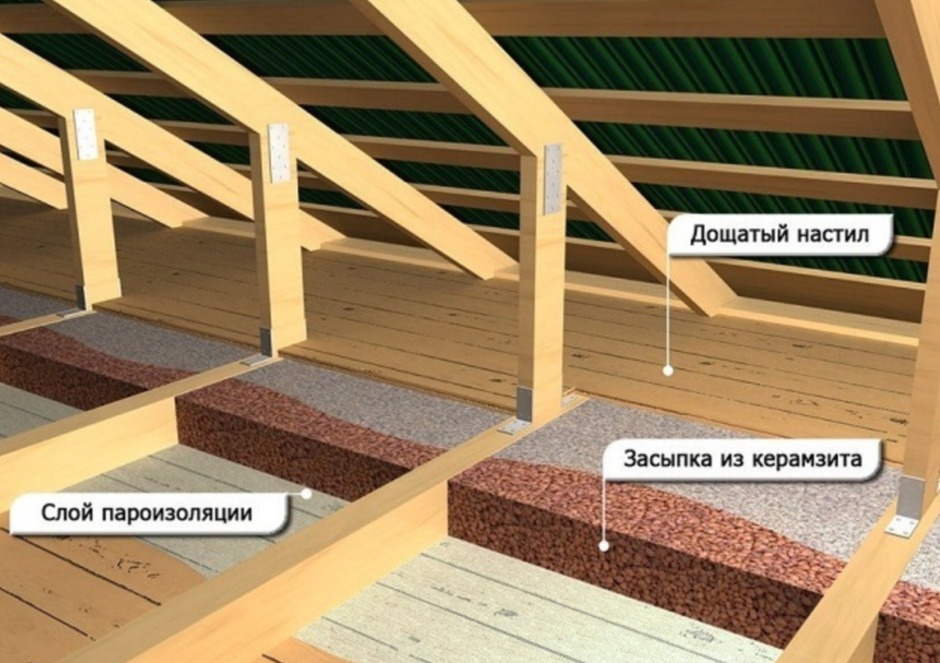

Laying backfill thermal insulation

Working with it occurs according to the following scheme (using expanded clay as an example):

Here, more attention needs to be paid to the lower base, otherwise the insulation may spill out through the holes. For this, either boards or a special covering coating (roofing felt, glassine or vapor barrier) are used.

By the way! The first option, called rough sheathing or ceiling, is better suited for sawdust, the second - for ecowool.

In the first case, all gaps between the boards should be covered with clay or lime. If sawdust is used as the material, then an acceptable option is when they are mixed with clay or lime mortar. In this case, the need to seal the boards is reduced, but in the case of clay, fire safety is increased.

The second option is more labor-intensive, but at the same time economical. As in the installation of non-bulk materials, the canvases are laid, attached to the boards and taped with reinforcing tape at the joints. In the case of roofing felt, bitumen mastic is used for this.

Thermal insulation material is poured over the base. If ecowool is used, it should be compacted well, as it is prone to shrinkage.

Next, the waterproofing is stretched. Its purpose is to allow moisture evaporating from the thermal insulation to pass through, but to prevent it from entering from above. If necessary, an attic floor is laid.

How to insulate a ceiling from inside a house

To do this, you will need the following step-by-step instructions:

- Floor beams are attached to the Mauerlat.

- The beams that will subsequently be attached underneath are prepared: they are cleaned of mold and treated with an antiseptic.

- Fixed around the perimeter of the Mauerlat.

- Temporary retaining boards are laid on the beams (they are not secured with anything).

- The waterproofing is stretched over them and fixed with a construction stapler on the bars and beams. This is the only step that is carried out from the outside. Adjacent canvases are overlapped.

- The sheathing crossbars are placed under the beams at right angles to them (the resulting squares are the size of the thermal insulation strips).

- The insulation is being prepared. The slab is adjusted to size, the roll is cut.

- It is laid between the beams, above the sheathing elements, and leans against the waterproofing.

- For reliability, the insulation is tied with twine.

- A vapor barrier is placed and secured with tape and staples.

- The final step is installing the ceiling.

Ceiling insulation has its own nuances, but if you understand them, then it is quite possible to carry out this work yourself.

Regardless of whether there is heating or not in the house, it is necessary to insulate the house evenly, eliminating cold bridges. About 4 years ago I contacted the tower completion and reconstruction department. I've been looking for someone to do it for a long time. The house has been well insulated, now you can live outside the city at any time of the year; in the summer I don’t heat it at all.