Soundproofing the ceiling in an apartment with a suspended ceiling

As they say, you don't choose your neighbors. And they are often quite noisy. Many people face a similar problem. And everyone solves it in different ways. Some naively believe that it is enough to create an air gap and extraneous sounds will disappear on their own. This is what makes many people install suspended ceilings in their apartments. Poor knowledge of physical laws affects this. This solution is completely unable to solve the problem. To get rid of extraneous noise from the apartment above, you should either purchase special suspended ceilings or insulate existing ones. Multilayer or perforated fabrics have similar properties, and we will find out what additional materials to use further.

The content of the article

Is sound insulation necessary for tension coverings and why?

Such ceilings are made either from PVC film or fabric. Both materials can dampen sound by no more than five decibels. In fact, this is very little, especially if the neighbors are too noisy.

Attention. It is also worth considering the fact that in some cases a suspended ceiling can act as a sound wave amplifier.

There are two reasons for this. The first is that sounds that occur indoors reach the ceiling and are reflected. The result is an echo effect.

The second reason lies in the air pocket itself, which exists between the main and suspended ceilings. It acts as a resonator: it can amplify some sounds that are emitted from above, which will create discomfort not only for the owners themselves, but also for the neighbors. All this leads to the understanding that it will not be possible to do without additional sound insulation when installing suspended ceilings. And there is more than enough space to place it. There is a lot of space between the main and suspended ceilings.

Materials for better sound insulation

There is a wide variety of different soundproofing products. The following types are most effective to use with stretch ceilings.

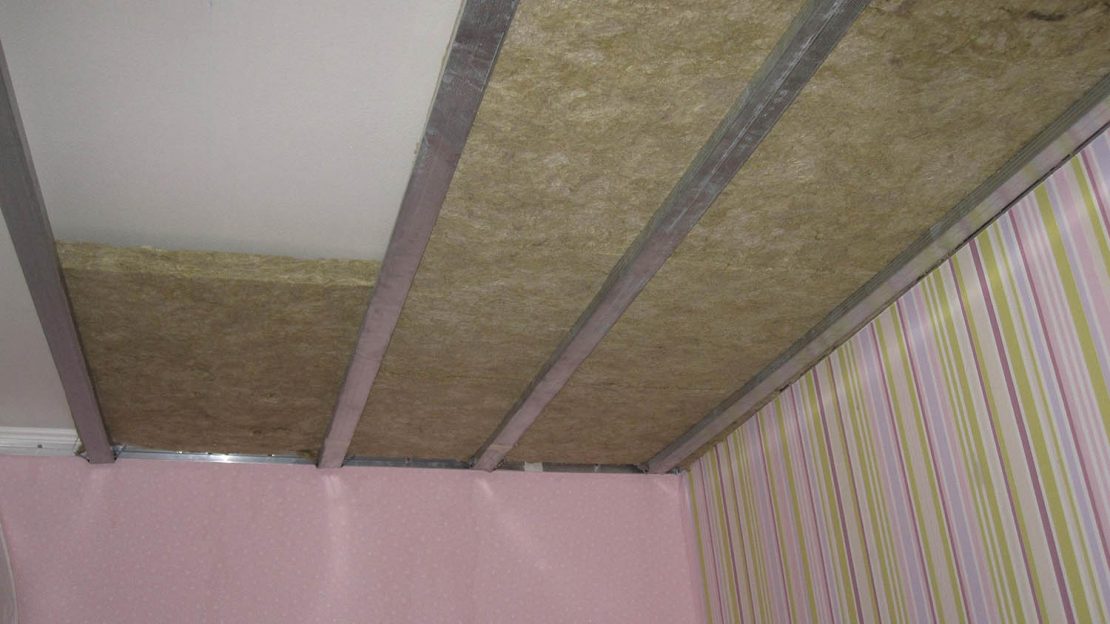

Mineral wool

The thickness of the roll can vary from 100 to 150 fifty millimeters. The material has good sound absorption properties. The coefficient reaches 0.95. But it is not very convenient to install. To ensure good sound insulation, it is necessary that the wool fits tightly to the main ceiling, and does not reach twenty millimeters to the tension ceiling. Typically, disc dowels are used to secure insulation. But since they conduct sound, this reduces the protection effect. It becomes weaker as the number of fixatives increases. Instead of such dowels, a frame mount is more suitable.

Basalt slabs

This material is made from stone or glass fibers. The thickness is fifty millimeters.Their density is higher than that of cotton wool, which is more convenient for installation. Basalt slabs retain their shape better and retain extraneous noise. The higher their density, the better they protect.

Soft fiber boards

For their production, natural wood fiber is used, which is pre-crushed and soaked. After this, it is placed under a press and dried. The slabs are quite dense and provide good protection against low-frequency noise (this includes bass in music). The material has a small thickness (ten to twenty millimeters) and absorbs sound well.

Thermosound insulation

This is a multilayer composite material. It consists of three layers, securely connected to each other. In the center is a glass fiber canvas. Using this material, you can provide high-quality protection not only from noise, but also from temperature surges. True, it also has a negative feature, like everything based on fiberglass. If its particles get on the skin or mucous membranes, irritation may occur. To avoid this, the fiberglass is separated on both sides by a layer of propylene. With a thickness of only fourteen millimeters, the material copes well with noise.

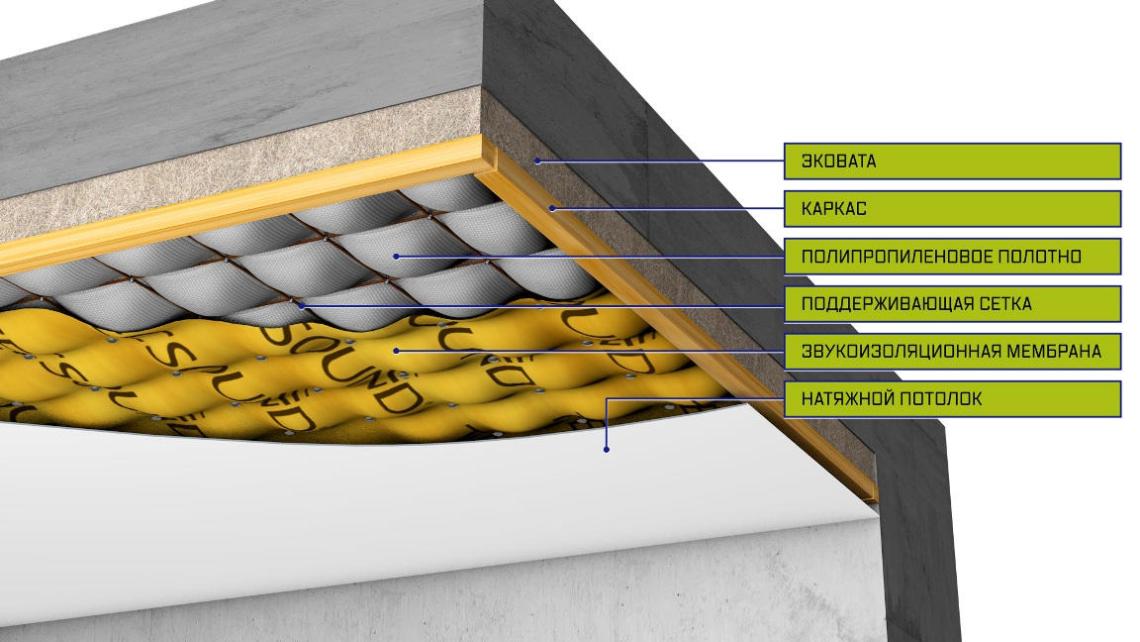

Soundproofing membranes

They have a small thickness. They are successfully used with both stretch and suspended ceilings. With a small thickness that does not exceed five millimeters, it has high sound insulation characteristics.

Zips panels

Of all the options presented, this one is more suitable than others for use without a frame. But its characteristics in reality are lower than those declared by the manufacturer, since there are no vibration isolations.

Unsuitable materials for sound insulation

This is how people are designed: they are constantly looking for ways to save money. This desire also applies to sound insulation. In this regard, many myths were born. For example, that material manufacturers deliberately deceive customers. Their goods are too expensive, but you can get by with less.

But practice says something completely different! All attempts to make it cheaper or even free of charge do not lead to anything good. A list of materials that clearly will not improve noise protection is given below.

Soundproofing from the car

Due to its small thickness, many users are simply fascinated by this material. And no wonder. A normal soundproofing design takes up too much usable space in the room. And the “auto noise” has a thickness of no more than a few millimeters. The benefit is obvious, but this is only at first glance. Although it copes well with sound insulation in a car, it does not justify trust in an apartment. And what should you ask of her? It was created to be applied to a thin sheet of metal, and not to a thick ceiling. And the noise inside the car and indoors are completely different in nature.

Acoustic foam

Often used as a material for sound insulation. But it was created for slightly different purposes and is not able to influence the noise level.

It is needed to reduce the echo of the room. Its purpose is to remove echo and improve acoustics in every possible way. Now, if you are setting up a home theater in the room or equipping a place for sound recording, this is where it will definitely play its role.

Cork

Oddly enough, most people firmly believe that if they cover their ceilings with cork, all the troubles with noisy neighbors will disappear by themselves.It is good as a substrate for flooring, as it dampens vibration well. However, its properties as protection against sounds are very low.

Stretch ceilings for sound insulation

Today there is no need for additional sound insulation for suspended ceilings. On sale you can find types with sound protection.

These products are from Europe, where they are produced by Cerutti and Clipso. Such ceilings are divided into two types:

- made of perforated fabric;

- made of smooth multi-layer coating.

The first type of product is a polyester mesh treated with liquid polyurethane impregnation. The decorative coating has a huge number of tiny holes. They refract sound waves that pass through them. Their amplitude is dampened, causing the noise to subside.

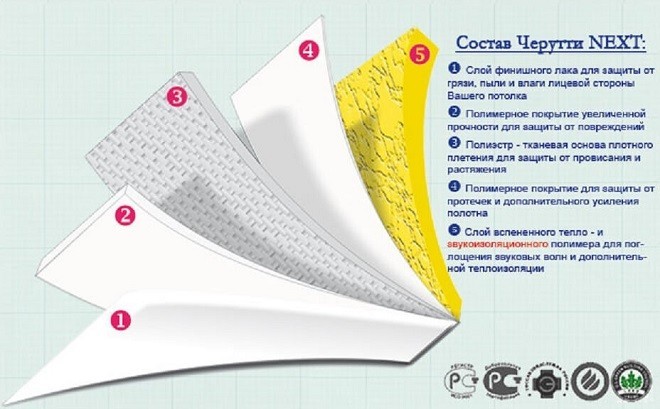

For smooth multilayer acoustic analogues, fabric materials are used. This gives sufficient strength to the coating. A layer of polymer is applied to it on both sides - this makes the fabric more elastic and enhances its performance. Impregnation with a special varnish is applied to the front side, making the decorative surface more attractive and aesthetically pleasing. Finally, a foam sound insulator is used. In addition to noise-absorbing characteristics, such a ceiling prevents heat from escaping from the room.

DIY soundproofing methods

To protect against noise in a room, three different methods are used. However, when insulating ceilings, only two of them are used.

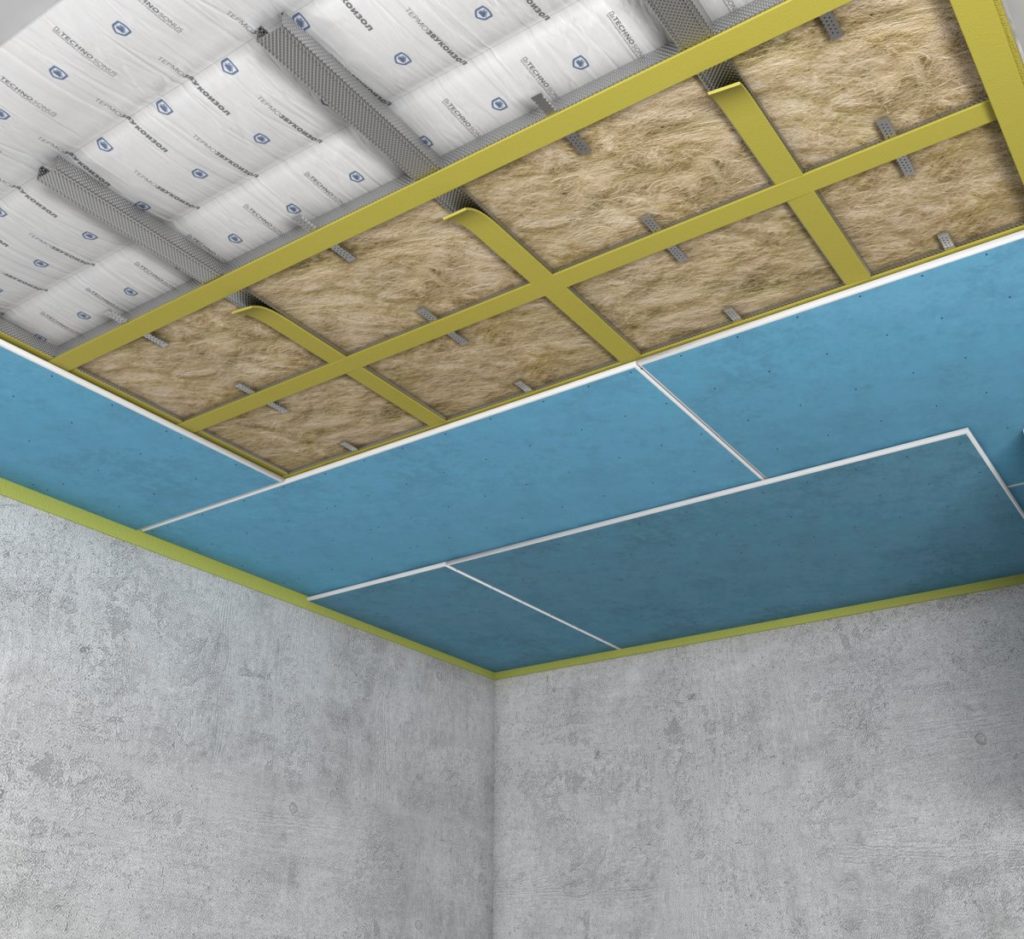

Frame method

First you need to install the guides that will carry the panels. In the spaces between them there is a material that absorbs sound. Next, you should install panels that will reflect it.However, if the room is used as a recording studio, they will absorb sound rather than reflect it.

This method allows you to achieve excellent sound insulation. But it is quite expensive and you will have to sacrifice useful space.

Frameless method

Sound absorption material is placed directly on the ceiling. After it is glued, it is covered with panels or plaster is applied to it.

If you follow the technology exactly, the quality of sound insulation will be no worse than when using the frame method. At the same time, the cost is greatly reduced.