Soundproofing the ceiling under plasterboard in an apartment

Housing in multi-storey buildings has poor sound insulation. Any loud sounds behind the wall can be heard by all neighbors. Many are trying to improve sound insulation. You can do this for all surfaces in the home or just for one, if the area is small and every square meter is valuable. Sound insulation of ceilings under plasterboard is carried out using various materials. A certain order of work must be followed. It is worth taking a closer look at this issue.

The content of the article

Do-it-yourself ceiling soundproofing installation technology

The process begins with choosing a suitable material. There are several types of them on the market. Each has certain features that are worth considering. Then they select the necessary equipment, prepare the surface and move on to the main stage.

Tools for work

The material planned to be used for sound insulation is prepared in advance. You will need a tape measure, drywall and acrylic sealant.You will also need scissors capable of cutting metal, metal profiles, high-quality rubber gaskets and a level. It is recommended to use self-tapping screws for fastening. Additionally you need a hammer drill.

Preparing the ceiling for finishing

This is an important stage of soundproofing. It is necessary to get rid of all cracks and crevices, even small ones. Sound will penetrate into the room through them, which will reduce the quality of insulation. Defects can be easily corrected with plaster. But it is recommended to start by removing the old cladding. Then they clean the surface from dust and begin plastering.

Reference. The quality of the sound insulation performed depends on how well the base is prepared. This stage cannot be neglected.

You should start applying markings. You can use a professional laser device if available. Plumb lines and a tape measure are also suitable. Only after this they begin to assemble the aluminum structure.

When working with the frame base, you should use pieces of sealing tape. This will reduce the noise level from vibrations almost completely.

Assembly of aluminum structure

It is recommended to assemble it based on the markings made earlier. The distance between the profiles should not be greater than the dimensions of the slabs of the selected insulating raw material. Otherwise, it will not be tightly secured, it will begin to fall out, and the noise will not be reduced. When assembling the frame, it is important to check how securely all its elements are held. When the structure is ready, wiring and other necessary communications can be inserted into it.

Fixation of insulating materials

When assembling the frame, the raw materials used for insulation should be taken into account. Its dimensions must match the constructed structure.Then the frame base is attached to the surface. Then you can start filling it with an insulating product. It is important that it holds tightly, does not fall, does not crumble.

Drywall installation

When the insulating material has filled the frame, they begin to fix the drywall - from the far corner of the room. The slab is applied to the ceiling, checked to see if it fits in size, and fixed. Self-tapping screws are used for this. For one sheet of drywall, it is recommended to take about 50 pieces of fasteners - for greater reliability of the structure.

When the first sheet is fixed, the further direction of the web is chosen independently. Seams should be kept to a minimum. Otherwise, sound will come through them. When the work is completed, all joints are sealed with putty or sealant for additional insulation.

Filling voids

It has already been noted that all joints must be additionally sealed with a suitable composition in order to improve the insulating properties of the created structure. You can also use acoustic options so that less sounds penetrate into the room from outside.

Only an integrated approach will provide high-quality protection.

Methods and materials for sound insulation, their characteristics

It was noted that there are several types of insulating products. Each has certain nuances that influence the final choice. This also determines how good the sound insulation will be.

Mineral wool

The material is quite soft, which allows it to absorb noise well. The advantage of using it is its low cost. This is the best way to carry out sound insulation economically. Among other types of products for similar purposes, this is the cheapest. Installation of mineral wool is simple.It is sold in slabs, so it is enough to attach them to the structure and make sure that everything is held securely.

Extruded polystyrene foam

It has good characteristics. Reduces the penetration of sounds from outside into the room and allows you to retain heat. By choosing this product, you can solve several issues at once. It is important that special glue must be used to secure the polystyrene foam. There are many analogues of the product, but you should not replace it. It is distinguished by good density and hardness. Therefore, it is he, and not similar options, that is capable of qualitatively reducing the noise level.

Soundproofing membranes

This is a special membrane lining. It is characterized by its small thickness and good properties. It is important that during installation it is necessary to mount it not on the frame itself, but under it. It protects against vibrations. Thanks to its thinness, it will not only eliminate excess noise, but also will not “take away” the height of the ceiling.

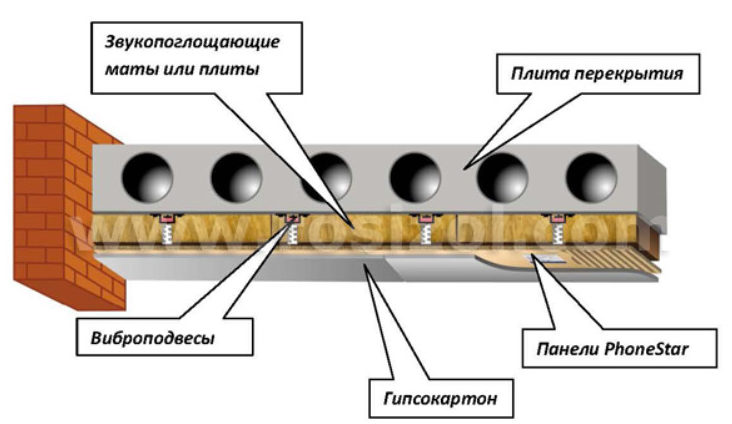

Vibration suspensions as a way to improve sound insulation

This device is popular and is used more often than other types. The design is quite simple, but has good sound insulation properties. Vibration suspensions vary in appearance, characteristics and cost. Their variety allows you to choose the appropriate option for a specific ceiling and conditions.

Natural fiber

Basalt wool can be used, the basis of which is natural raw materials. The structure of the product is fibrous, which allows it to effectively isolate the space from noise. Like mineral wool, this material is sold in slabs. This simplifies installation work. Also, natural fiber allows air to pass through well, which prevents mold from developing on the surface.It is one of the highest quality options for noise protection. Can be used not only inside the room, but also outside.

Liquid insulation

The essence of the method is to apply a special composition in the form of paint to the ceiling. Even one layer can reduce the amount of noise penetrating inside and retain heat. The advantage is that there is no need to build and secure a frame. An excellent option for apartments with low ceilings, where every centimeter is important.

You can do noise insulation yourself. It is necessary to choose the right material, prepare the surface and carry out high-quality installation. Before work, you should take into account the characteristics of the room, the desired result and financial capabilities.