Installation of slatted ceiling

If you want to get a modern and beautiful ceiling made by yourself, you should pay attention to slatted structures. There are many advantages to installing them, but there are practically no disadvantages. This type of suspended ceilings looks very modern and stylish, easy to do, if you wish, you can install it yourself, and it will serve for a long time. In the article we will analyze in detail the assembly process with our own hands.

The content of the article

Installation of an aluminum slatted ceiling: step-by-step guide

The design is a type of suspended ceiling consisting from panels from 2 to 4 meters in length and from 5 to 20 centimeters in width. Their thickness is about 0.6 mm. Each lamella has its own connection. It is also possible to order non-standard sizes.

Thanks to the approved dimensions, it is easy to calculate the amount of material per room and include the amount of costs in the estimate.

Often, for aluminum structures, spotlights are installed through cut holes in the plates. The panels lend themselves well to painting. You can choose the color you like from the palette or transform them into a mirror surface.

Metal the coating is well suited for rooms with high humidity or industrial premises. It is worth noting that installing panels in small rooms of the correct shape is possible without outside professional help. This type of coating lends itself well to dismantling.

Required materials and tools

Before we begin installing the ceiling, we prepare the equipment and components. For independent work you will need a standard set of tools:

- level;

- drill;

- screwdriver;

- roulette;

- metal scissors;

- self-tapping screws

Having all of the above will make the job much easier.

Accessories for slatted ceilings

Usually consumables are included in the packaging to the design and included in the price.

- Rails are aluminum panels with special connections.

- Tires are strips with teeth onto which slats hook.

- Suspensions are wires that are attached to a concrete surface, and tires are hung on them.

- Skirting is a plastic or metal part that closes the gap between the wall and the ceiling.

Having checked the presence of everything listed, we proceed to installation.

The main stages of installing a slatted aluminum ceiling

Assembly rules are simple and just require careful measurements. We act in stages:

- Surface marking. Draw a line using a water or laser level 13 centimeters along the walls from the plane.

- Make holes along the drawn strip every 40–60 cm and secure the supporting profile with self-tapping screws and dowels.

- Attach the guide profile using adjustable hangers.

- Drive anchors into the holes and attach hangers to them.

- Install support rails.

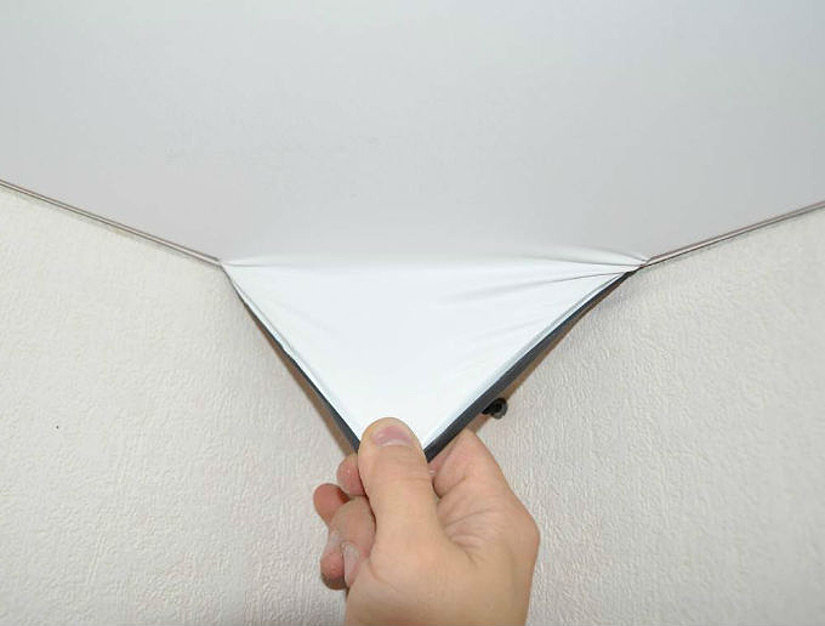

- Remove the protective film from the slats and snap them into place.

If necessary, cut additional holes for lamps.

Slatted ceilings in the bathroom: design advantages

Hanging structure in the bathroom performs a number of additional functions and has significant advantages in comparison with other ceiling design options. It hides defects and communications, air conditioning systems running under the slats.

The structure also serves as a frame for installing lamps, which are easily mounted in pre-cut holes. It is not afraid of dampness, does not lend itself to corrosion and the formation of harmful mold.

Additional sound insulation will be a nice bonus.

The slatted ceiling is suitable for a wide variety of premises from private residential buildings to industrial institutions and offices. His installation will not cause any problems if you have minimal construction skills and tools. In addition, they are famous for their high service life at low cost and ease of maintenance.