Gapless stretch ceiling

Stretch ceilings are a stylish and modern way of finishing a surface. They appeared relatively recently, but today there are the latest technologies that offer an original design.

A gapless profile is an opportunity to install the canvas as close as possible to the wall, ensuring a perfect fit of the planes. Upon completion of installation, no additional inserts or decorations will be required.

I'll tell you more about this technology.

The content of the article

Gapless profile for suspended ceilings – what is it?

The harpoon method of fastening appeared immediately, but over time it changed greatly. And so installers began to offer gapless installation, which appealed to customers. Despite the high cost, people often choose this finishing option.

The installation method assumes that the film adheres perfectly to the wall. The gap between the surfaces is minimal.

No additional decor or baseboards will be required. The design looks attractive and features similar characteristics of a conventional stretch ceiling. They are durable, installation is simple and quick, and if necessary, it is easy to dismantle and reinstall.

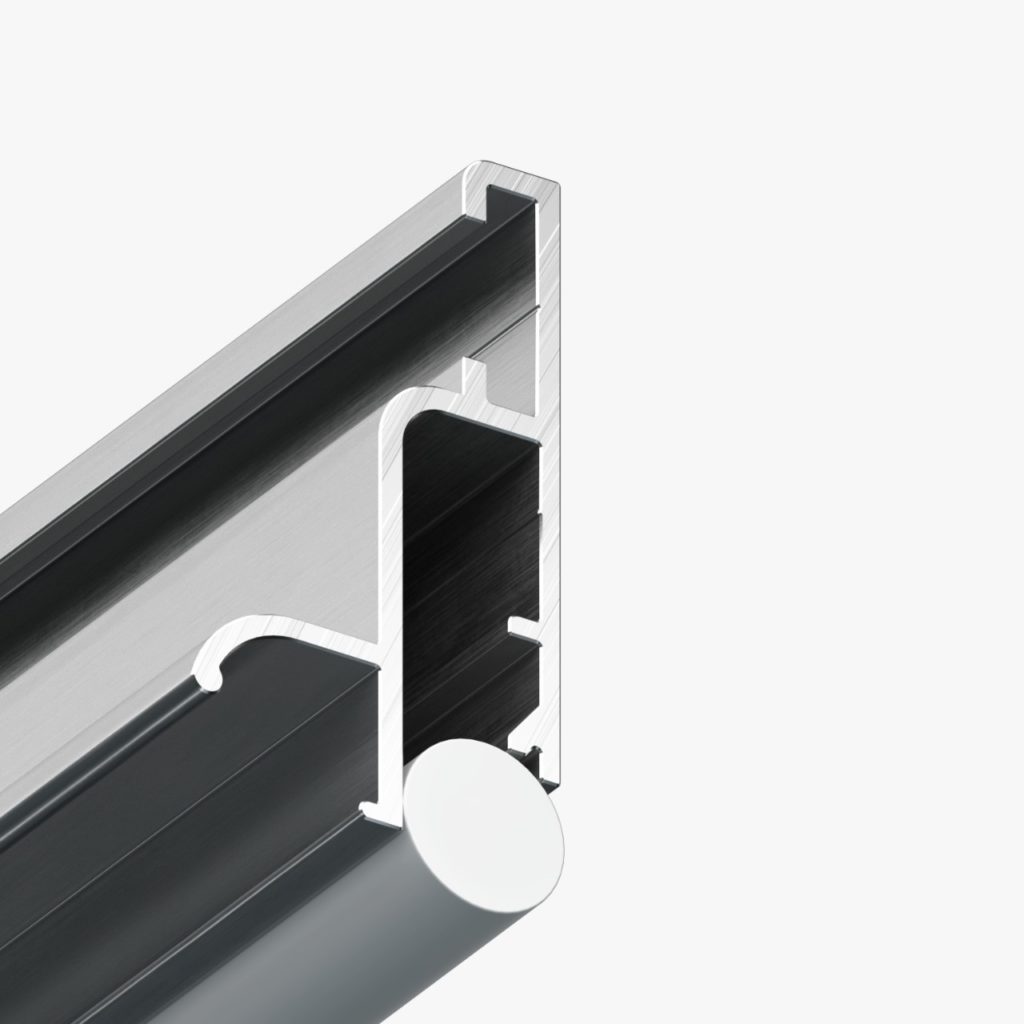

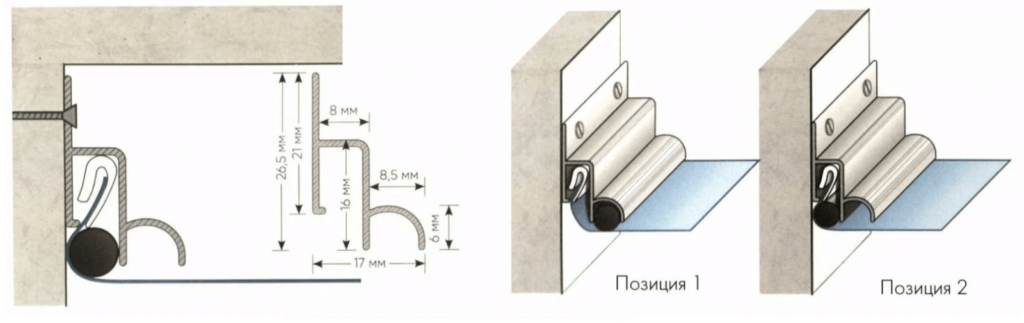

The profile is H-shaped and has a slight bend on the outside of the mount. This is the part of the lock that fastens the profile and the harpoon with a reliable hook.

The elastic fabric is cut out exactly according to the size of the room and a hard, convex harpoon is attached to it. With its help, a fastening occurs, which is installed very close to the wall.

Advantages of gapless ceilings

The technology for installing a KRAAB stretch ceiling with a gapless fit of the canvas is in demand today. The gap between the wall and the ceiling is small and not visible with the naked eye. Unlike KRAAB, the EUROKRAAB system involves installing the canvas with a slight separation from the wall. The distance does not exceed 5 mm, but this allows you to create the effect of a “floating” ceiling.

It is important to understand that the installation will be of high quality if the walls are leveled to perfect condition.

The harpoon, fixed over the entire surface of the canvas, has a movable middle part. This makes it easy to install it into your profile. No special spatula is required: it is inserted with your fingers and snaps into place. A rigid structure is formed that is not subject to deformation or bending.

The main advantages of the design

You can talk endlessly about the advantages of a gapless profile. This reliable and attractive design, which is easy and quick to install in the room, and also remove if necessary. Its cost is slightly higher than usual, but not critical.

Among the main advantages of gapless ceilings are:

- no need to install baguettes and ceiling plinths;

- variety of mounting profiles - for figured ceilings, a thin mount is produced that bends, creating original shapes;

- ease of dismantling: if necessary, simply remove it and then install it in place without the help of special tools and damage to the profile and material;

- clear lines and curves;

- attractive appearance.

I note that in real life the ceiling looks even more attractive than in the photographs. The absence of additional decor and unnecessary elements is ideal for clear and precise interiors, for example, in the minimalist style.

Installation Features

The installation of the structure is no different from the usual stretch ceiling technology we are used to. To begin with, measurements are taken and the installation height of the canvas is verified. The minimum indentation is 6 cm from the ceiling slab.

Next, specialists proceed according to the following scheme:

- the plane is checked with a laser level;

- a fastening profile is installed at the prepared points, dowels and screws are used, the distance between the fastenings is 30–50 cm;

- material with a harpoon already sealed into it, cut to the shape and size of the room, is installed in the profile, and no additional tool is required;

- heating the canvas with a heat gun.

As you can see, the installation method is no different from the standard one, but additional equipment is required. Therefore, for high-quality installation, it is better to contact the manufacturers. They will do everything quickly and using established technologies.

The installation process begins from the outer corner of the room.

In the entire production scheme of a gapless ceiling, special attention is paid to proper measurements of the room. If they are done incorrectly, the result will not please the residents. Herself installation is simple and does not require additional skills. After installation, company representatives advise using silicone, colorless sealant around the perimeter. It is applied to prevent water from entering the room in case of flooding.