Installing corrugations on the hood

Corrugated pipe is a pipe that is used as air ducts. Products of evaporation or combustion pass through it. It is installed between the equipment. Thanks to the corrugations, clean air always remains in the room, as ventilation occurs when connected to the kitchen hood. As for appearance, it can be rectangular or round. The first of them is usually used in manufacturing plants. Another model can be found in residential premises. Possible composition: plastic, galvanized or stainless steel, textiles are the least common. Installing a corrugated hood is a sure way to keep your kitchen fresh.

The content of the article

Varieties

Corrugations have several varieties:

Plastic. A budget option. There are many models of this type. But the general characteristic is the least air resistance that is created inside the pipe. It is easy to clean and works quite quietly. ATTENTION! It is worth remembering about the fragility and possible harm to human health, since a large amount of smoke is released during fire. In addition, the cheapest devices can emit an unpleasant odor. Installation is difficult. Afraid of high temperatures.

Plastic. A budget option. There are many models of this type. But the general characteristic is the least air resistance that is created inside the pipe. It is easy to clean and works quite quietly. ATTENTION! It is worth remembering about the fragility and possible harm to human health, since a large amount of smoke is released during fire. In addition, the cheapest devices can emit an unpleasant odor. Installation is difficult. Afraid of high temperatures.- Aluminum. Not particularly heavy, high chance of long-term performance, high temperature tolerance.However, during operation it can produce specific sounds and increased vibration. There are inconveniences during cleaning.

- Insulated. Its peculiarity is the presence of a layer of foil with mineral wool. This type can be installed on any hood.

- Other. All of the listed disadvantages of previous models are absent (smell, noise, flammability, service life) + is durable. But this type is not cheap. Not everyone can afford them.

What are the diameters of corrugations for hoods?

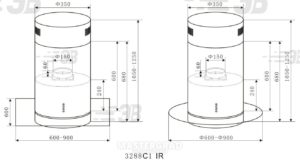

There are the most popular corrugations, the values are 100 mm, 125 mm and 150 mm (for a kitchen hood). In industrial applications it can reach 200 mm, 250 mm, 300 mm. The choice depends directly on the power of the device. The diameter of the hood itself should be taken into account accordingly; they must match. If you want a large diameter, then you should also find an adapter to connect it to the neck. The dimensions of the corrugation for the hood have several classic parameters. You can always find the minimum value in the kitchen hood instructions. The most commonly used are 100 mm and 120 mm. If you still cannot find the size, then use a larger one; this is especially good for the kitchen: the noise will decrease due to the low flow rate. With a reduced diameter, air will be pushed through, experiencing difficulties.

There are the most popular corrugations, the values are 100 mm, 125 mm and 150 mm (for a kitchen hood). In industrial applications it can reach 200 mm, 250 mm, 300 mm. The choice depends directly on the power of the device. The diameter of the hood itself should be taken into account accordingly; they must match. If you want a large diameter, then you should also find an adapter to connect it to the neck. The dimensions of the corrugation for the hood have several classic parameters. You can always find the minimum value in the kitchen hood instructions. The most commonly used are 100 mm and 120 mm. If you still cannot find the size, then use a larger one; this is especially good for the kitchen: the noise will decrease due to the low flow rate. With a reduced diameter, air will be pushed through, experiencing difficulties.

Installation

How to install corrugation on a kitchen hood yourself and why? To ensure that the air is renewed regardless of whether the hood is on or not, it is worth attaching the corrugation through the grille to the ventilation hole. Because the hole has a compartment for the air duct and for air removal. When installing, it is also necessary to take into account the technical characteristics - the size and length of the pipe, otherwise all the work done will be impractical.Remember the quality and reliability of the material you choose. Besides, it’s better when everything is done in the same style, to match the interior. Please understand that cost does not guarantee a proper installation, so do your research on collation. It also says how to install an air duct for an exhaust hood in the kitchen.

How to install corrugation on a kitchen hood yourself and why? To ensure that the air is renewed regardless of whether the hood is on or not, it is worth attaching the corrugation through the grille to the ventilation hole. Because the hole has a compartment for the air duct and for air removal. When installing, it is also necessary to take into account the technical characteristics - the size and length of the pipe, otherwise all the work done will be impractical.Remember the quality and reliability of the material you choose. Besides, it’s better when everything is done in the same style, to match the interior. Please understand that cost does not guarantee a proper installation, so do your research on collation. It also says how to install an air duct for an exhaust hood in the kitchen.

How to choose the size

It is necessary to measure the entire length with a tape measure. And take into account the route along which the air duct will pass. For example, its possible path lies through a closet, along the walls or along the ceiling. After calculations, it is worth adding about another 10 to 15 percent to the total length. This is an important point before connecting the corrugation to the hood.

IMPORTANT! Check the stretched corrugation size. It is worth taking the length with a margin. Ideally, it is 3 meters, but even if there is a completely extra length, it will not hurt.

In the opposite situation, if there is a shortage of material, you can attach the missing piece using tape, but this option will reduce the permeability of the air duct. This should be resorted to only in extreme cases. With the fewest angles, but with a larger degree, the hood can work much more smoothly.

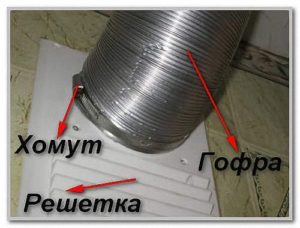

How to attach a corrugation to a hood

In order to somehow connect the corrugation to the hood, you will need:

- corrugated pipe

- self-tapping screws

- clamps for fixing the sleeve or soft wire

- ventilation grille or adapter

- silicone sealant

- adapters, there was no corrugation of a suitable size

How to attach the corrugation to the hood after all the tools are ready:

- Before work, you should clean the ventilation in the apartment

- To begin, stretch the corrugation along its length and check the component elements. Avoid kinks, then the air draft will remain good.

- Use sealant to lubricate the hood neck

- Put on the corrugation and secure it with a clamp; if there is none, then wrap it with wire.

- It is necessary to lay it this way until the end of the ventilation hole.

- Fix the ventilation grille with self-tapping screws

- Then put on the corrugation with sealant

- Secure the work with a clamp

- Check the exhaust system by connecting the hood to the mains. This is done as follows: turn on the hood at maximum power, now take a sheet of paper and bring it from below to the grille. A sign of correct mounting is that the leaf is held, which means air is being sucked in. That's it, the problem of how to put the corrugation on the hood is solved.

REFERENCE! Do not wipe the outer surface, this will relieve you of unwanted odors.

You need to know that a ventilation hole is required. The shaft cannot be closed completely.

If you do not want the corrugation to be on public display, then there is an opportunity to hide it. How to insert the corrugation inside the hood so that it is not noticeable? This can be easily done using wall cabinet doors, decorative boxes or other elements. To disguise it, you need to choose a color to match the furniture. To add harmony, try to decorate everything based on the style of the kitchen. Another option is to install an overlay. It can be formed along the contour of the cabinet, thereby ensuring the secrecy of ventilation. It will not be difficult to install it inside kitchen units. However, this will waste a lot of necessary space, and will also add holes that will need to be cut.

If you do not want the corrugation to be on public display, then there is an opportunity to hide it. How to insert the corrugation inside the hood so that it is not noticeable? This can be easily done using wall cabinet doors, decorative boxes or other elements. To disguise it, you need to choose a color to match the furniture. To add harmony, try to decorate everything based on the style of the kitchen. Another option is to install an overlay. It can be formed along the contour of the cabinet, thereby ensuring the secrecy of ventilation. It will not be difficult to install it inside kitchen units. However, this will waste a lot of necessary space, and will also add holes that will need to be cut.

If you don’t want to figure out how the corrugation is attached to the hood, then you can simply order professional installation. Especially if the kitchen was made together with a custom-made hood.Then, installation of the corrugation for the hood may not proceed according to the standard scheme.

Why do you need to install corrugated hoods?

The good thing about using corrugated pipes is that they have many advantages. For example, most can afford to install them, and installation, as it turns out, is quite simple. In addition, they have a wide range of types and sizes and low compressed weights. They are resistant to high temperatures and therefore do not burn. It is possible to install both indoors and outdoors, which indicates functionality. They are placed in different planes and used in different areas of systems. You just need to take care once and the freshness in the room is guaranteed for a long time.

The good thing about using corrugated pipes is that they have many advantages. For example, most can afford to install them, and installation, as it turns out, is quite simple. In addition, they have a wide range of types and sizes and low compressed weights. They are resistant to high temperatures and therefore do not burn. It is possible to install both indoors and outdoors, which indicates functionality. They are placed in different planes and used in different areas of systems. You just need to take care once and the freshness in the room is guaranteed for a long time.

Corrugated hood for the kitchen (it's just a pipe like a sieve and can't work).