Connecting the hob to the mains

A hob is an essential item in the kitchen, while the electrical panel is one of the most powerful electrical consumers in the apartment.

A hob is an essential item in the kitchen, while the electrical panel is one of the most powerful electrical consumers in the apartment.

Before installing hobs, for safe and long-term use, you must familiarize yourself with the basic rules for connecting them to the electrical network.

The content of the article

Requirements for installing the hob

Installation of hobs can be carried out independently only in compliance with certain rules.

Providing ventilation

First: the room where they are used must be equipped with a ventilation system.

It is recommended to install hoods above the burners to absorb fumes from the food being cooked on the stove.

It is necessary to comply with the requirements for the distance from the hob to the lower area of the hood.For electric stoves it should be at least 70 cm, and for gas stoves - 10 cm more.

Tabletop requirement

The second rule is related to the ability of the countertop on which the equipment is attached to withstand high temperatures: at least 100°C.

Important! Due to the specified conditions of use, the thickness of the material must be at least 25 mm.

Admissible Neighborhood Limits

The next requirement requires that the device be installed so as to leave a distance between the boundaries of the stove area and the vertical surfaces located around it: walls and bodies of adjacent cabinets. It should be 15 cm, no less.

Direct wiring line

When connecting electric hobs to the electrical network, it is necessary to use a straight wiring line from the panel to the device. It must be connected to a protective grounding device (RCD) of a rating corresponding to the power consumption.

How to connect an induction hob to the mains

There are no fundamental differences in connecting an induction panel from a classic electric hob. The details of the process are detailed below.

Selecting a cable to connect

Typically, when choosing a cable, you are guided by two main parameters: the number of cores and thickness.

Number of cores

The first parameter depends on the number of contacts in the plug or terminal block of the connected device.

Hobs have two connection options: 3 or 4 wires.

- Three wires are used when supplied from a single phase network (220 V).

- If 2 or 3 phases (380 V) come into the panel, then it is more advisable to connect the induction cooker using a 4-wire circuit, since in this case less current will flow through the wires.Consequently, they will heat up less and the consumption efficiency will be higher.

Cable thickness

Once you have decided how many phases there are at the input and according to what scheme the stove will be connected, you need to correctly calculate the thickness of the cable.

Help: depending on the power of the device, wiring with a thickness of 4 or 6 mm2 is suitable.

It should be taken into account that for low-power plates the terminals are designed for a wire thickness of 4 mm², and when trying to connect to conductors of a larger cross-section, certain problems may arise.

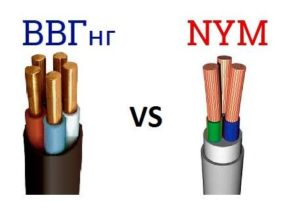

Type and design

If we talk about the type of cable and its design, then you can use both hard and soft (consisting of multi-wire conductors) copper wiring options, preferably with increased fire protection.

Help: some of the most popular brands are: NYM, VVGNG, VVGNG-LS.

Craftsmen who constantly work with cable products, especially for large-section wires, prefer to use soft liners. The cores in it consist of a large number of copper wires tightly intertwined.

- Firstly, such a cable heats up less, since the current spreads along the surface of the conductor, and not inside it. And a solid wire has a significantly smaller total conductive surface.

- Secondly, flexible cable is much easier to work with, especially when installed tightly.

The only disadvantage of a stranded conductor is the need to purchase lugs or sleeves to attach it to the terminals.

Connection diagram

Distribution network options

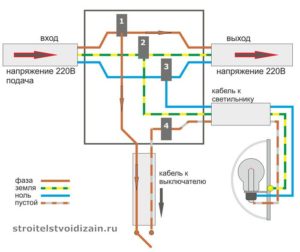

Before considering the diagram for connecting the device to the network, it is necessary to list the distribution network options that are found in houses and apartments and, accordingly, the number of cores in the internal electrical wiring.

- Two-wire is the most unfortunate option for a single-phase network without grounding: “zero” and phase come. This option is not acceptable for connecting most household appliances, especially a powerful induction cooker.

- Three-wire - “zero”, “ground” and one phase are supplied from the network. Such wiring will allow you to connect the device using a three-wire circuit if the allocated power is sufficient.

- Four-wire wiring is a rare option used in modern new buildings. In addition to grounding and neutral wire, 2 phases come.

- Classic three-phase network - five lines are supplied, three of which are phases. Typical for large private houses with high allocated power.

Reference. Options 3 and 4 are most preferable for use in the hob connection diagram, although they are not always available.

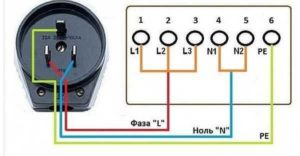

Device contacts

The induction hob is not supplied with a cord and plug due to the variety of options for the internal power distribution network (see above).

As a rule, the device has 6 inputs on the contact group, which are designated as follows:

- L1, L2, L3 – phases;

- N1, N2 – zero contacts;

- PE – grounding.

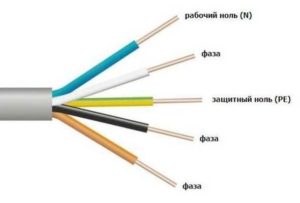

ATTENTION! Electrical wiring has generally accepted color codes.

- For the ground wire, yellow or yellow-green braid is used.

- For “zero” - blue.

- Phase conductors can be of any color, but usually brown or black insulation is used in a two-phase network.

- And to distinguish the phases of a three-phase network - yellow, green and red markings.

Connection to panel

Now it's time to move on to connecting the wire to the panel.

- To do this, you need to turn it over with the burners down and on the reverse side find the cover that hides the group of contacts.

- Unscrew the fixing bolt and free access to the terminals. If a jumper is installed between the neutral and ground terminals, it must be removed.

- First of all, ground the device by fixing the yellow-green wire in the terminal marked PE.

- Since we only have one neutral wire coming from the panel, connect it to terminal N1, and close the second terminal with a jumper.

- Just in case, make sure that the phases are disconnected by placing a test screwdriver against them.

- Connect the remaining wires to the terminals marked L. Connect the remaining power inputs with jumpers to the connected one.

The work on the consumer side is complete.

Connection via panel

Before starting work in the panel, turn off the input switch and use a tester to make sure that the panel is completely de-energized. The line going to the device is switched into the distribution network in the usual way.

ATTENTION! If there is no grounding in the network, you must seek help from a qualified electrician. Without a ground connection, operation of the hob is prohibited.

- The ground wire is fixed to the ground bus. Connect the phase to the circuit breaker (1 or 3 phase).

- On the other side, connect the machine to a protective grounding device, to which also connect the neutral wire going to the device. As an alternative, you can use a circuit with a differential machine. Use ratings that match the level of power consumed by the equipment.

- Before applying electricity to the input of the panel, in order to avoid a short circuit, make sure that the opposite end of the electrical cable is connected to the device or to an outlet. Otherwise, its conductors must be insulated.

How to connect a surface using a plug and socket

When purchasing a power socket and plug kit, you should take into account what maximum current it should be rated for and how many contacts (3 or 4) will be used.

The suitable socket rating is 25 or 32 A.

The current level is easily calculated using the formula: I = P / U, where:

- I – current strength, A;

- P – plate power, W;

- U – voltage, V (equal to 220 or 380 V, depending on the connection circuit).

When connecting an outlet, use color coding for the wires. This will avoid incorrect electrical switching, which can lead to equipment failure or melting of network sections.

Attach the socket body to the wall, connect the wires to the terminals in accordance with the markings indicated on the product.

Also observing the polarity, connect the plug to the wire.

Make sure that the wiring diagrams of the plug and socket match. Check the voltage in the phase contacts of the socket, then carefully insert the plug into it and turn on the hob.

How to connect a surface without a plug

An alternative to connecting an electric hob to electricity is a direct connection scheme using a terminal box.

This option has a number of advantages - it is more reliable and visual. Errors when connecting wires are practically eliminated.

The downside is the inability to quickly disconnect the stove from the electrical line.To de-energize the device, you will have to manipulate the panel.

Reference. To connect to the terminals in the box, the ends of the wires are twisted into a ring shape.

For a flexible type of cable, such twisting must be additionally tinned or lugs for fork or ring type terminals must be used.

How to connect a gas hob

A gas hob is connected to electricity if it is equipped with an automatic ignition system. The same applies to combined options. For example, the hob of the stove is connected to gas, but is equipped with an electric oven.

Such models consume a small amount of power, so you can easily use a standard electrical outlet to connect them.

No special measures are required to connect electrical hobs.

However, you should pay attention that when connecting a gas stove to electricity, it is not recommended to use a metal corrugated liner, since if a spark hits it, a fire may occur.

For safety reasons, it is recommended to use a gas hose.