Why does the Ardo washing machine have problems? Their elimination. Why doesn't the Ardo washing machine work?

Over time, as you use it, questions arise about the malfunctions of the Ardo washing machine and their elimination. Most often, the heating element, bearings or drain pump fail. The control unit may also break, which is a more serious failure. A description of the main causes, methods of diagnosis and repair can be found in the presented article.

The content of the article

Control module failure

Each machine has a control module, that is, an electronic board with a processor that controls the operation. Normally, this unit works properly, but it can be damaged due to voltage surges in the network or due to drops of moisture getting on the semiconductors. Because of this, contacts and tracks burn out, oxidize, and the following symptoms appear:

- the machine does not start;

- it turns on, but the drum does not rotate;

- the unit operates normally, but does not drain water;

- The program settings are lost during washing;

- The car freezes and does not respond to commands for a long time.

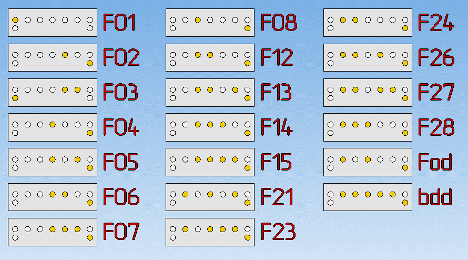

As a rule, faults in the Ardo washing machine are detected automatically. The display may display code F2, F5, F13, F14. If a failure occurs for the first time, it is recommended to simply unplug the plug from the outlet and wait 10-15 minutes.

But if it occurs again or the Ardo washing machine does not work at all, you must contact a specialist. It is extremely difficult to carry out diagnostics or repairs on your own. Moreover, a specialist can identify a software failure, which will require a complete replacement of the board.

Drain pump failure

The pump fails because forgotten objects, locks, buttons, even parts of thread get into it. Gradually, dirt and foreign objects accumulate, causing the impeller to become unable to move. Therefore, the motor works with great effort and may burn out. Such malfunctions of the Ardo washing machine can be determined by a number of signs:

- the water does not drain at all;

- the water leaves, but noticeably slower than usual;

- the pump motor is too noisy, extraneous sounds have appeared;

- There is no usual noise at all during draining.

As a result of self-diagnosis, the machine will display error code F4 or E00, or maybe E01 or E02. In these cases, you need to disconnect the device from the network, remove the panel and remove the pump. If it's just clogged, just clean it. But if the blades or the motor itself are broken, a complete replacement will be required.

Breakage of heating element

The heating element fails over time in almost any machine. It is durable, but gradually insoluble salt deposits accumulate on the surface, which is associated with increased water hardness. Such malfunctions of the Ardo washing machine with vertical loading or horizontal loading can be determined by a number of signs:

- the water does not heat up well and remains cool (during washing, you need to touch the glass with your hand - it should be noticeably hot);

- The washing program is interrupted and F2 appears on the display;

- there is a burning smell;

- the machine in the meter is knocked out due to high voltage, and this happens exactly at the moment when heating should start.

If such a breakdown of the Ardo washing machine occurs, you need to turn off the device and clean the heating element. It is not necessary to remove it - you can simply put 150 g of citric acid in the powder tray and run the hottest wash. If this does not help or there is a burning smell and the water does not heat up at all, the heating element definitely needs to be changed.

Such a breakdown of the Ardo washing machine interferes with normal washing, and in advanced cases can even lead to a short circuit. During repairs, the unit is turned off, the heating element is removed and exactly the same is purchased, then it is installed in its original place.

Bearing wear

The reasons for the breakdown of the Ardo washing machine may also be related to wear of the bearings. They suffer due to constant vibration, drum overload, and prolonged use. As a result, the seal weakens and allows water to pass through, so the bearings themselves rust and collapse.

You can diagnose the problem yourself using the following signs:

- poor spin (or its complete absence);

- During spinning, the unit makes a lot of noise;

- if you swing the drum by hand, it starts to wobble;

- in advanced cases, the drum may even go down and stop rotating.

To eliminate this problem, it is necessary to replace the bearings with new parts. If you don’t have the necessary skills, it’s better to contact a specialist. Do-it-yourself repairs can lead to even greater damage.