How to check a washing machine motor

One of the most important elements of a washing machine is the engine, without which it cannot work. Therefore, in the event of a malfunction, it is necessary to carry out a full diagnosis of this electrical component.

The content of the article

About engines

To quickly fix a breakdown, first of all, you should determine which motor is located in the device.

Important! The washing machine, depending on the manufacturer, has a certain type of engine, which has its own characteristics, so checking each model will be significantly different.

There are 3 main types of motor units:

There are 3 main types of motor units:

- Direct drive – used in modern automatic machines (LG, some SAMSUNG models). Such a three-phase electric motor is connected to a drum, has a multi-pole commutator, a rotor surrounded by permanent magnets, and also a high level of efficiency, so the price of machines with such an electric motor is high.

- Asynchronous motor has a simple design, which consists of a starter and a rotor, but its large dimensions and low efficiency make the motor unprofitable, so it is not used in modern cars.

- Commutator motor has many advantages that facilitate its use in modern washing machines (small size of the device, high speed does not affect the operation of the engine). The improved motor design allows the belts to transmit rotation from the motor to the drum. You can repair all the parts yourself.

Checking a direct or asynchronous motor

Attention! Direct drive or induction motors are connected directly to the drum and are therefore not intended for home testing.

Electric motors of these types can display errors on the device display, which indicate turn short circuits, network breaks or brush faults. But professional inspection and maintenance of the motor must be carried out by specialists using certain instruments.

Checking the commutator motor

The commutator type of motor is the most common in modern cars. It can be easily removed from the case and checked independently. To do this, you should combine the stator and rotor, and also apply a voltage of 220 V through an additional ballast (heater), making sure that the active resistance and power of the equipment does not exceed 500 W.

The commutator type of motor is the most common in modern cars. It can be easily removed from the case and checked independently. To do this, you should combine the stator and rotor, and also apply a voltage of 220 V through an additional ballast (heater), making sure that the active resistance and power of the equipment does not exceed 500 W.

When connected to the mains, the motor begins to rotate, and the autotransformer does not overheat, which means the motor is working normally.

To correctly diagnose a washing machine engine, you need to remember the most important and common breakdowns of the motor department:

- failure of electric brushes;

- rupture or damage to the stator or rotor winding;

- delamination of lamellas.

Checking the brushes

Attention! The wear of the brush can be determined by visual inspection, the presence of sparks when the engine is running, or the appearance of sounds during washing.

Electric brushes can wear out due to an overloaded tank during washing, using maximum speed during spinning, and also when there is a short circuit in the turns of the motor winding. For each model of washing machine there is a certain type of brushes, which should be purchased in a specialized store.

Important! If the new brushes are not used to all parts of the engine compartment, strong sparks may occur.

Hard brushes will last longer, but excessive hardness can negatively affect the commutator and lead to its failure.

Rotor check

To detect a short circuit or break in the rotor winding, you must have a special device - a multimeter, which measures the resistance level between the lamellas (within 20–200 Ohms). If the maximum level appears, this means that a break has occurred. If the level is low, a short circuit has occurred.

To detect a short circuit or break in the rotor winding, you must have a special device - a multimeter, which measures the resistance level between the lamellas (within 20–200 Ohms). If the maximum level appears, this means that a break has occurred. If the level is low, a short circuit has occurred.

When switching the multimeter to buzzer mode, you can check whether the rotor is shorted to the iron package by connecting one end of the device to the rotor iron, and the other should be moved along different lamellas. In this case, the multimeter device should not make sounds.

Stator check

Just as when checking the rotor, a multimeter is also needed here, which must determine the inter-turn short circuit using a signal emitted when all ends of the wiring are short-circuited in turn.

Just as when checking the rotor, a multimeter is also needed here, which must determine the inter-turn short circuit using a signal emitted when all ends of the wiring are short-circuited in turn.

It is also necessary to check the machine for wiring breakdowns. To do this, you should connect the multimeter with one end to the body of the washing machine, and alternately connect the other through the wiring.The appearance of sound indicates that the insulation is broken and the machine may receive an electric shock.

Important! If such problems are discovered, the right decision would be to buy a new engine, since repairs may be more expensive.

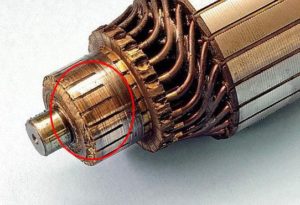

Checking the slats

Small plates - lamellas, which transmit current through the brushes, are not subject to wear, but if the engine jams, they can peel off from the shaft to which they are glued. In case of minor delamination (0.5 mm), a collector groove can be made. To do this, you will need fine sandpaper, which you need to sharpen the lamellas well and clean the entire space around from chips.

Small plates - lamellas, which transmit current through the brushes, are not subject to wear, but if the engine jams, they can peel off from the shaft to which they are glued. In case of minor delamination (0.5 mm), a collector groove can be made. To do this, you will need fine sandpaper, which you need to sharpen the lamellas well and clean the entire space around from chips.

There may also be a more serious problem where the wiring of the lamella from the rotor breaks, then you need to solder the wiring in the right place with a soldering iron.