How to put on a belt in a washing machine

The belt in a washing machine is a very important part that is necessary to rotate the drum. It is put on the engine and on the pulley that is screwed to the engine.

The rotation of the drum begins with the operation of the motor, then the rotational movements are transferred to the pulley. This design is very simple and in most cases is used in various industries.

The rotation of the drum begins with the operation of the motor, then the rotational movements are transferred to the pulley. This design is very simple and in most cases is used in various industries.

Sometimes cases arise when the belt falls off and the drum stops spinning. Repairs will require a little effort and time.

The content of the article

How to replace a belt on a Samsung washing machine

For Samsung-branded equipment, the back cover cannot be removed, which greatly affects repairs.

To repair equipment you need:

- buy the same item. You can select it by marking or by a broken element;

- electrical tape 10 to 15 cm long;

- wire with a thickness of 05 to 0.8 mm and a length of 50 cm;

- wire cutters;

- lighting fixture;

- crosshead screwdriver.

Before you start adjusting, carefully check the gear and drum pulley.The gear has several compartments for counter elements near the belt. Installation of the device must begin from top to bottom.

Please note that when placing the strap on the drive gear, you need to correctly get to the place where the old element of the device was previously installed. If you install the item close to the gear, you will not be able to tell how the installation went. It is possible that part of the strap will sag or be located at the very edge of the pulley. After which you will have to make adjustments again.

Please note that when placing the strap on the drive gear, you need to correctly get to the place where the old element of the device was previously installed. If you install the item close to the gear, you will not be able to tell how the installation went. It is possible that part of the strap will sag or be located at the very edge of the pulley. After which you will have to make adjustments again.

As soon as the new part is on the gear, it must be positioned with a slight offset to the side. You need to choose the location of the pulley when it has support from turning the equipment. The fasteners will not help to secure the belt from turning. The equipment always tries to move to the other side, where it will stop with the help of a stop.

In order to secure the belt, you need to use electrical tape, and to prevent damage, you need wire. You need to secure the wire on top of the electrical tape. Then make 5 to 10 turns and twist the edges together. Then you need to rotate the pulley to install the belt correctly.

As soon as this element is in place, you can hear the click of the belt. It will no longer be able to spin, since it will be held securely by a homemade clamp. Then we turn the gear in the other direction and remove the electrical tape with the wire. The renovation is complete.

This process takes no more than 15 minutes if you carry out the repair strictly according to the instructions. To check the design, rotate the pulley. The strap will fall into place and align itself.

How to change the belt on an Indesit washing machine

Buy a strap from a manufacturer from a reliable supplier.Then completely remove the old element and its remains. Any belt has a cord that, when broken, unravels and winds around the device’s motor or nearby wires.

Buy a strap from a manufacturer from a reliable supplier.Then completely remove the old element and its remains. Any belt has a cord that, when broken, unravels and winds around the device’s motor or nearby wires.

The new element must be placed on the engine and its upper part pressed tightly to the pulley. You need to simultaneously spin the drum while pulling the completely new element onto the pulley.

The strap should be positioned strictly in the center of the pulley, which is located on top. This can be done by moving the belt 2 tracks on the pulley at the bottom of the equipment. After which you can start the device for washing clothes.

How to put a belt on an LG washing machine

To replace the belt on LG equipment yourself, you need to unscrew the bolts from the back of the case and remove the fixing cover. For this you need a Phillips screwdriver. After this, clean the pulley from the old element.

To remove the old belt, you need to pull it to the side and turn the pulley. Very often there are cases when the old element breaks or slips off. It must be found and removed from the machine body.

Then we put a new belt on the engine, and then on the pulley. To install a new element on the pulley, you need to pull it onto a circle and then turn it. After all these manipulations, make sure that it is exactly in place and pressed tightly against the groove. Rotate the pulley to ensure that the repair is correct.

If everything is done correctly, you can reinstall the retaining panel and secure it with the mounting bolts.

Briefly about belts in a washing machine

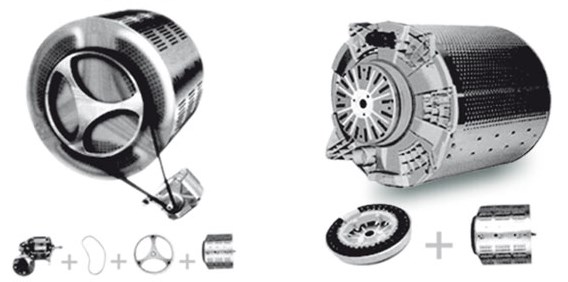

Types of belts

There are two types of belts for washing machines. They differ from each other only in the tension force and additional control.

In most cases, such a belt is used for asynchronous motors. It is made of high quality and especially durable materials. The wedge element must be very tightly pulled onto the washing machine equipment with a slight deflection of up to 5 mm when pressed with a finger.

Tension is carried out by moving the motor. To do this, you need to unscrew the fasteners in advance. If there is not enough engine adjustment to ensure proper tension, the belt must be replaced.

The installation of the wedge element begins with the motor pulley, and then this element is installed in the groove of the washing machine drum pulley. You need to hold the belt in the groove with one hand and turn the pulley with the other until this element is completely in place.

V-ribbed belt

This element is perfect for commutator motors. It has a jagged shape. Belts can vary in length, width, shape and number of wedges.

This element is perfect for commutator motors. It has a jagged shape. Belts can vary in length, width, shape and number of wedges.

Repair and replacement are exactly the same as for the wedge element. The only difference is that the serpentine belt is located in the middle of the counter pulley, as on the drum and motor.

The tension of this element is slightly lower than that of the other model. Therefore, tension must be done by rotating 360 degrees. If the belt is too tight during repairs, be careful as your hands may be injured.

Extending the life of the belt in the washing machine

Expert advice

In order for the machine strap to last longer, you need to monitor the weight of the laundry. Because it is the weight of wet clothes that causes imbalance during washing or spinning.

Causes of belt failures

Belt wear

In narrow devices, all elements are located very close to each other and to the body. Therefore, at the moment of wear, such parts are free and rub against each other, causing severe wear.

Cracked drum pulley

There are several reasons: the pulley is cracked, the automatic machine was overloaded, the element is not tensioned correctly. A broken pulley cannot hold the belt, so it needs to be replaced.

The cause of the failure is wear of the bearings

Severe wear can lead to high vibrations of the spin unit and the device drive. When they reach their peak, the strap stretches, slips, or breaks. After which repairs are required.

Incorrect loading and operation of the washing machine

The belt can fly off if the drum is not loaded correctly and excessive vibration is caused. This element can dry out and become very thin if the equipment sits idle for a long time.

The belt can fly off if the drum is not loaded correctly and excessive vibration is caused. This element can dry out and become very thin if the equipment sits idle for a long time.

Very often, in side-loading machines, plastic parts exhibit fatigue deformation, which leads to a violation of the arrangement of the elements. After which the strap may fly off along with the pulley shifting. In such situations, it is better to buy a new device than to adjust the equipment.

Video instruction

In order to clearly understand the repair, you can watch the video instructions.