Why does the sewing machine not pick up the bobbin thread?

Thanks to the development of technical inventions, special machines for embroidering clothes were invented and developed. Over time, their design and design have undergone many changes and have become available for personal use. Now every seamstress and hardworking housewife has a special sewing machine. Thanks to her, she creates her masterpieces and delights her family and friends with them, inventing new images and models. Its advantages are the speed and good quality of product creation.

Thanks to the development of technical inventions, special machines for embroidering clothes were invented and developed. Over time, their design and design have undergone many changes and have become available for personal use. Now every seamstress and hardworking housewife has a special sewing machine. Thanks to her, she creates her masterpieces and delights her family and friends with them, inventing new images and models. Its advantages are the speed and good quality of product creation.

But unfortunately, it often happens that the device does not work properly and there is a risk of thread and fabric breaking. Often the problem is related to improper grip of the thread. This problem is quite easy to solve on your own. In our article we will analyze the possible causes of the problem and suggest ways to solve it.

The content of the article

How does a sewing shuttle work?

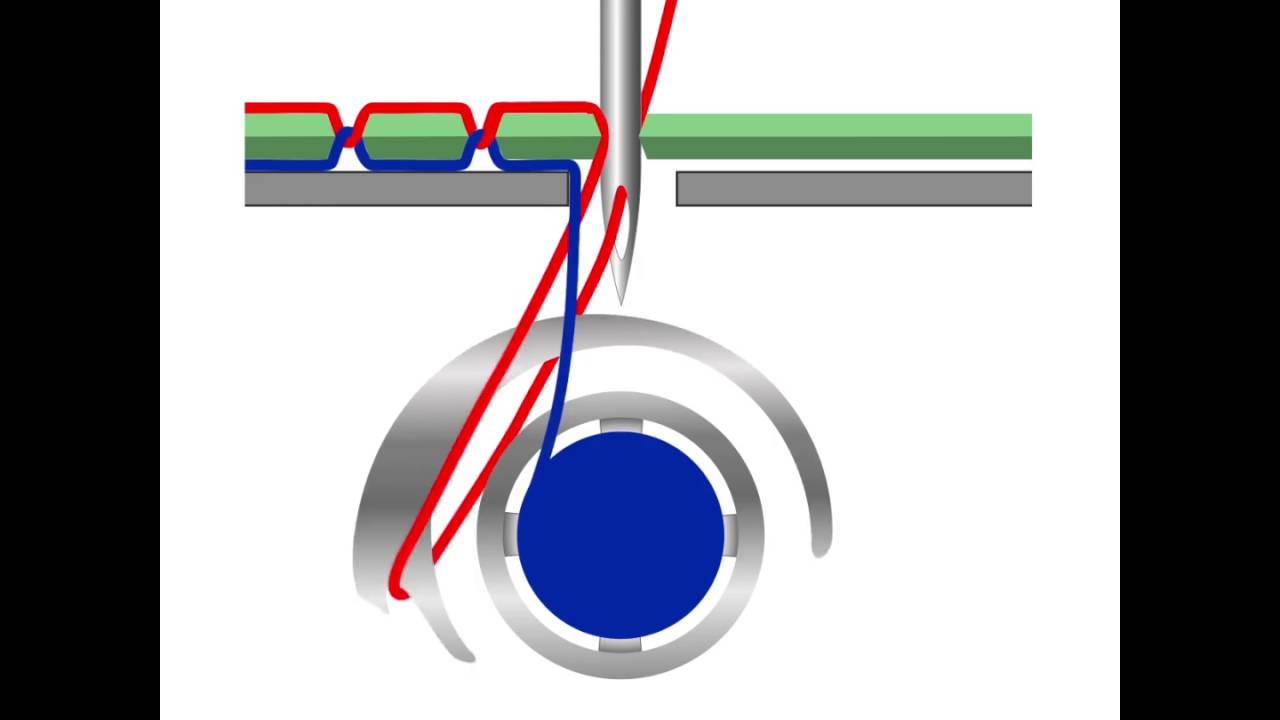

The main element that ensures the operation of a modern device is the sewing hook. In order to understand the possible causes of malfunctions, you need to know the principle of its operation.

The rotating shuttle grabs the thread at the right moment using a specially pointed nose.To thread the thread, a needle is used, which makes rapid movements up and down vertically. Depending on the year of manufacture of the model and the cost of the product, the machines differ in speed and reliability of the device. But the principle remains unchanged and is carried out only thanks to the exquisitely selected and combined work of the shuttle.

IMPORTANT! For proper operation and a high-quality seam, it is necessary to very accurately calibrate the needle and the part of the shuttle that grips the thread.

Possible reasons why the hook does not catch the bobbin thread

To properly eliminate the cause of the problem, you need to thoroughly inspect the sewing machine and identify the source of the problem. They are mainly of the following types: technical problems and human factors.

The blunt part of the shuttle that catches the thread. She just slides off of him.

The blunt part of the shuttle that catches the thread. She just slides off of him.- Calibration violation and displacement of the needle or hook.

- The needle holder does not provide sufficient insertion of the thread and its correct grip.

- Incorrectly selected thread thickness. It is important to use such a thread at the bottom so that it is thinner in diameter than the top. At the same time, it also has its own limitations in terms of thickness.

- The needle used is not suitable for the selected fabric type.

- Also, work will not be carried out if the thread suddenly breaks. In this case, the shuttle will spin in vain.

There are other causes of malfunction, for example, contamination of the working surface or damage to it. Carefully inspect the body.

How to troubleshoot a sewing machine that won't pick up the thread

Once you have inspected the machine and identified the source of the problem, you can begin to fix it.Act according to the reason, you need to correct the shortcomings found. Here is a sample action plan:

Check the thread tension, first adjust by hand, and then go through a test stitch and adjust again.

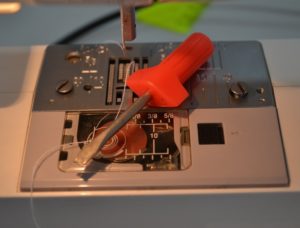

Check the thread tension, first adjust by hand, and then go through a test stitch and adjust again.- Clean the rotating part of the hook thoroughly. Small scraps, lint and other parts may be included. It is important to remove everything even from under the bottom edge.

- If rust or bent needle is detected, it must be replaced.

- If necessary, it is recommended to lubricate operating parts and components.

If these procedures do not help and the machine continues to malfunction, you should contact a technician for help. He will be able to identify the cause and fix it.

IMPORTANT! You should not replace important structural parts yourself, as this can lead to breakdown and disabling of the machine.

If there is no technical fault

It is important to take into account the human factor; perhaps the reason lies there. It happens that the tool is absolutely working, but the fact is that the seamstress installed and threaded the thread incorrectly. The operation of the machine also depends on this.

It is important to take into account the human factor; perhaps the reason lies there. It happens that the tool is absolutely working, but the fact is that the seamstress installed and threaded the thread incorrectly. The operation of the machine also depends on this.

Position the thread correctly at all stages of threading, from installing the bobbin to threading through the eye of the needle. Monitor the tension at all stages to prevent the thread from becoming too loose and to prevent the possibility of breaking.