What is a semi-automatic buttonhole in a sewing machine?

Those who love to sew clothes often face the problem of processing fasteners. The button closure is the most popular now, but this is where the main difficulty begins: sewing button loops. In this case, you should use one of two functions of the sewing machine: “automatic loop” and “semi-automatic”.

Those who love to sew clothes often face the problem of processing fasteners. The button closure is the most popular now, but this is where the main difficulty begins: sewing button loops. In this case, you should use one of two functions of the sewing machine: “automatic loop” and “semi-automatic”.

The content of the article

What is a semi-automatic buttonhole in a sewing machine?

So, when sewing any piece of clothing, one of the most difficult tasks is sewing buttonholes, the appearance of which is influenced by many factors, including:

- stitch density;

- symmetry;

- overcasting width;

- quality of fastening and cutting.

However, making a buttonhole is easy now. Some sewing machines have an “automatic buttonhole” function, some have a “semi-automatic” function.

“Automatic” allows you to make the desired stitch without much difficulty. So, you need to insert a button behind the special foot of the sewing machine. After this, pull out the reverse lever; if you forget to do this, you will have to turn off the machine and unravel the already made loops, ruining the fabric. The next step is to place the needle at the beginning of the loop and press the pedal. The stitch size is calculated automatically during overcasting.

When choosing a machine, you should pay special attention to the foot: its fastening must be strong so that it does not move during operation and does not quickly become unusable. The material - metal, plastic or others - often does not play a big role. It is difficult to buy a spare foot: very often the height or some other parameter is not suitable.

IMPORTANT! The button should not be larger than 2.5 centimeters in diameter, otherwise you will have to make a buttonhole by hand.

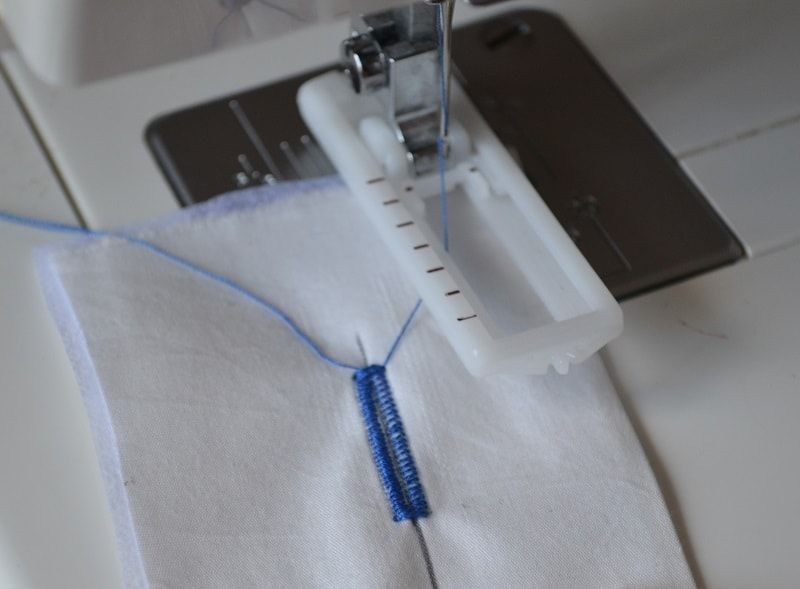

The situation is different with a “semi-automatic”: to sew a button you will have to go through several stages:

- Place the button sewing foot.

- Place the needle where the loop will begin.

- Enable the “Semi-automatic – mode 1” setting.

- Press the pedal and the machine will make the first stitch.

- Go through the remaining 3 settings.

By changing the settings, the user does different actions: first stitch forward, stitch to secure at one end of the loop; stitch back, securing stitch at other end. Naturally, before this you should take measurements, that is, mark the beginning and end of the loop on the fabric. A sewing machine with an “automatic” function does all these actions at one time on its own.

As you can see, stitching with a “semi-automatic” is a complex matter: you need to switch 4 different modes, however, you have to do this quite rarely. In addition, in this way it is possible to control the stitch density, which is almost impossible in automatic mode.

REFERENCE! Historically, buttonholes have been placed differently on men's and women's clothing: on the left side for men, on the right side for women.

Advantages and disadvantages of automatic loop execution mode

The obvious advantage of the automatic mode is the speed and ease of making a loop. However, not everything is so simple: after carefully looking at what was done, a person can easily see that the stitches on different sides of the button were applied unevenly. In fact, this is a problem with any sewing machine except those controlled by a built-in computer and embroidery machines. This phenomenon is due to the fact that the speed at which the sewing machine moves the fabric backward is less than the speed at which it moves forward. Other reasons that are involved in this are the condition of the foot, the quality of the fabric, its thickness, etc.

To prevent such a difference from being noticeable, sewing machines are in most cases equipped with a reverse stitch regulator. With its help, it is possible to equalize the difference in the speed of the machine forward and backward. It may seem that such precision is unnecessary, but sometimes it can ruin the entire look of the garment. Therefore, when purchasing, it is advisable to pay attention to whether this regulator is included in the package or not. The ideal option is to try out the machine by making one loop in the store.

Which is better: automatic loop or semi-automatic?

So, if you have to make a lot of buttonholes, then it makes sense to buy an automatic sewing machine, but it is worth remembering that such a device will cost much more. In most cases, such a loop only needs to be made once or twice a month, so a “semi-automatic” is a more adequate choice, considering the price.

It is believed that a better result can be achieved only with electronic machines that make up to 10 types of such loops; for example, with a peephole or with rounded edges. In addition, it is possible to enter the necessary characteristics of the loop into the computer, and the machine will make them at amazing speed.

The best result, according to professionals, can be achieved using a buttonhole machine, which independently cuts the loop without touching the stitches. So, as an option, they sometimes offer the purchase of such a device and a regular sewing machine - it will cost about the same as an electronic machine. Another option is to have the overcasting done by a tailor if you are using good fabric.

In the end, it all comes down to the fact that the choice of the right machine depends on the needs of the buyer - if he needs to make a lot of such loops: more than 20-30 per day, and of good quality, then it is advisable to purchase a machine with an “automatic machine”. Otherwise, a “semi-automatic” will be the best choice: you will save a lot.