Classification of sewing machine needles

If you follow the manufacturers' recommendations, the needles should be changed after 12 hours of continuous sewing. But this is the rule for replacing needles of the same type. If the machine is used to work with different materials, then the needles should be changed in strict accordance with the fabric being processed. After all, this is the only way to avoid defects and unpleasant breakdowns.

The content of the article

How to choose

The user instructions indicate the main characteristics of the needles that the sewing machine can work with. The easiest way to make the right purchase is to write down the necessary labeling and focus on it. If for some reason this option is not suitable, you should focus on the shape of the bulb and tip, the thickness of the rod and the size of the eye.

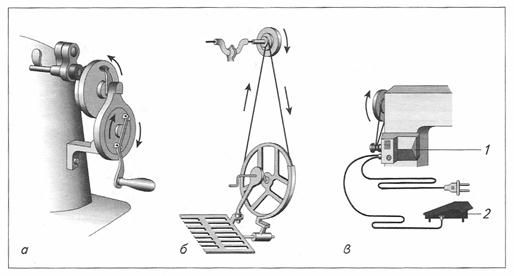

For household sewing machines

This technique is characterized by flasks with a flat (cut). This was done for the convenience of users - this makes it easier to correctly connect the needle when replacing it. You can distinguish them by their markings:

- universal - 130 / 705, HAx1;

- overlock: EL×705, HA×1 SP, DC×1, DB×1.

Universal ones are used both on household sewing machines and on similar overlockers. But if the marking indicates “specialization,” then using the needle on another type of device is prohibited.

To industrial

The main distinguishing feature is the round flask. Depending on the purpose, there are:

- overlock - DC×27;

- for lockstitch - DP×5, 134.

It is necessary to select a needle in strict accordance with the manufacturer's recommendations. An incorrectly selected flask leads to a number of problems associated with the incorrect working position of the tip and ear in relation to the shuttle.

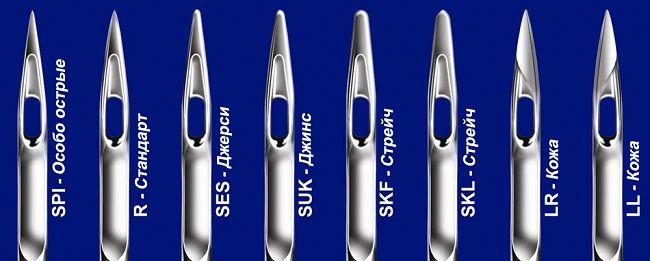

Letter meaning

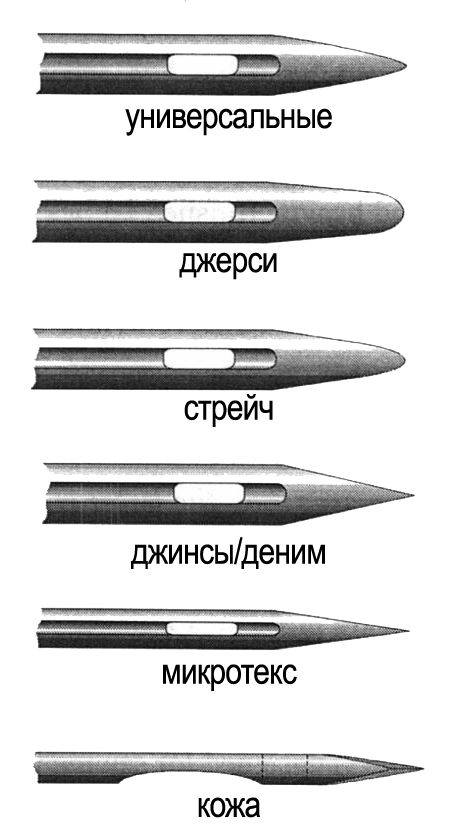

The letters following the flask marking indicate what materials and types of work the needles are intended for:

- H - slightly rounded tip, universal;

- H-J (jeans) - sharp, dense materials;

- H-M (microtex), SPI - very sharp, fine-fiber fabrics;

- H-S (stretch), SKL, SKF - rounded tip, elastic synthetic and natural materials;

- H-E (embroidery) - slightly rounded tip and special notch, decorative embroidery;

- H-EM - wide eye, for working with metallized thread;

- H-Q (quilting) - decorative stitching without visible punctures;

- H-SUK (jersey), SES - spherical point, for knitwear and knitted materials;

- H-LR, H-LL (leder leather) - cutting edge, leather;

- H-O - needle with a blade (one or two), decorative stitches with an emphasis on the holes;

- H-ZWI, H-DRI - double and triple, respectively, decorative finishing;

- Topstitch - for working with loose decorative thread.

Meaning of numbers

After the marking of the intended purpose comes the number (aka diameter) of the needle. It is denoted by a two-digit or three-digit whole number. There are metrics:

- European - hundredths of a millimeter;

- American - the same in inches.

Typically, manufacturers indicate the needle number taking into account both standards. For example: 80/12 (rod diameter 0.8mm/0.12in). For double or triple needles, another size is indicated - the distance between the axes of the rods.The marking becomes 2.5/80.

Types of needles for sewing machines

Thanks to the development of technology, new types of fabric are constantly appearing, when working with which a special structure of the tip, eye and even the rod is required. Otherwise, you can only dream of an even and durable stitch.

For knitwear

When working with such material, it is important to maintain the integrity of its fibers. As a result, it is recommended to select needles with a spherical point, which will push apart rather than pierce the threads of the fabric. H-S, H-SUK, H-SES are the best options for knitwear. When working with them, you will be able to form a beautiful stitch without compromising the strength of the fabric. And this will prevent the appearance of unsightly “arrows” spreading across the product from the seam.

For skin

This material must be cut through, since during classical piercing it is deformed and breaks through. The result is irregularly shaped holes and frequent needle breakages. Therefore, it is necessary to use tools with a cutting edge. When using H-LR, H-LL stitches, the stitches will be slightly tilted to the right or left.

For denim

This material requires thin and strong needles with a slightly rounded point. But even a correctly selected tool, when crossing denim seams, deviates from the axis, which leads to breakage or skipped stitches. To eliminate such troubles, the needle rod is supplemented with a cross-section of the groove.

For finishing stitch

This type of work often involves the use of low-strength decorative threads. The special structure of the large ear and a special groove along the shaft help prevent them from breaking or “loosening.”

Double needle

Without it, it is impossible to finish with double stitching.True, such a tool can only be used on machines with a zigzag mode, since 2 rods on one base require a gap in the needle plate. Double needles have taken their rightful place in the arsenal of embroiderers, since when using multi-colored upper threads they can create an interesting shadow effect.

With wings

It may have one or two blades intended for decorative stitching with holes along the seam. The wings push the threads apart, forming holes. Often used as one of the cores of a double needle.

Self-refueling needle

This option is also called “easy to thread”. A characteristic feature is a small slot leading to the eye, thanks to which, to thread the thread, you simply need to run it along the rod in the direction of the point. Due to its low strength, this needle is used only when working with light, medium-density fabrics.