How to thread a sewing machine

When working on a sewing machine, a lot of difficulties can arise, and if an experienced master is able to quickly cope with them, then a beginner may have serious problems. An experienced craftsman knows that incorrect placement of the thread can cause the stitching to be uneven and sloppy, and as a result, the fabric can completely deteriorate, which will lead to material costs. It is for this reason that it is worth taking a responsible approach to learning the basics of working with this equipment in order to try to eliminate as much as possible the likelihood of problems occurring, and if they do arise, be able to quickly correct them. The threading algorithm depends on the brand of your sewing machine. To become a master in this matter, you must first study the instructions included in the kit. If you don’t have one, we’ll try to figure out on our own how this can be done quickly and without errors.

When working on a sewing machine, a lot of difficulties can arise, and if an experienced master is able to quickly cope with them, then a beginner may have serious problems. An experienced craftsman knows that incorrect placement of the thread can cause the stitching to be uneven and sloppy, and as a result, the fabric can completely deteriorate, which will lead to material costs. It is for this reason that it is worth taking a responsible approach to learning the basics of working with this equipment in order to try to eliminate as much as possible the likelihood of problems occurring, and if they do arise, be able to quickly correct them. The threading algorithm depends on the brand of your sewing machine. To become a master in this matter, you must first study the instructions included in the kit. If you don’t have one, we’ll try to figure out on our own how this can be done quickly and without errors.

The content of the article

Features of the refueling algorithm

Singer sewing equipment is known for its performance and quality. This is an excellent choice for beginners who want to learn how to create real masterpieces with their own hands. The technology has parameters that make it very convenient. Learning to sew using equipment from this manufacturer is a pleasure. One of the main advantages of working on a machine is the ability to automatically operate the main working element. To place a thread element in a technique, it is necessary to follow a certain pattern.

You should work with Singer as follows:

- Place the coil in its place - at the top of the body. The manufacturer has provided a protective element, which eliminates the possibility of the reel jumping off.

- Pull the thread element to the thread receiver, then move to the bobbin.

- Go through the hole provided on the reel. The coil is located on the right side of the equipment body.

- Bring the machine into working condition, wind the required amount of thread onto the bobbin. Now you can remove the bobbin, ready for further use.

Using this diagram, you can wind on a bobbin. To place the thread directly into the eye of the needle, it must be raised; this can be done by turning the wheel, which is intended for control. Spin it towards you.

Using this diagram, you can wind on a bobbin. To place the thread directly into the eye of the needle, it must be raised; this can be done by turning the wheel, which is intended for control. Spin it towards you.

Place the coil in the appropriate holder, it is located on top, secure it with a cap. Using a thread guide, pull it through, the next stage of fixation will be a spring, which is designed for tension.

After this, follow the compartment located above the needle and go through the special lever. Next, move back and down, here do not forget about the tension device, this is a compact clamp that is located above the needle. The final stage will be threading the needle. Aim from front to back.

IMPORTANT.All actions must be performed only when the equipment is unplugged, otherwise the risk of injury is too high.

Threading errors

In the process of performing this operation, it is quite possible to make mistakes, which will affect the quality of your work. To eliminate the possibility of obtaining a poor-quality result, we will consider what errors there may be in order to anticipate them.

If the stitching loops or rings form, you did something wrong. This may be due to insufficient tension on one of the threads. Some needlewomen mistakenly believe that it is enough to check the correct installation of only the lower thread. This opinion is incorrect; only if each of the preparation operations is carried out clearly, will the equipment work correctly.

REFERENCE. The quality of the stitch largely depends on the correct installation of the upper thread.

For work, choose good quality threads. To ensure an even stitch, you should check whether the thread guide is functioning correctly. If it doesn’t tighten, correct the problem.

The most common mistakes:

The spring, which is responsible for the tension of the thread, does not press well. Therefore, it is not pressed well. Identifying this error is extremely simple. The foot is moved to the lower position, the thread is threaded into the eye of the needle and pulled up. Next, the foot is raised again, lowered and the thread element is pulled through. You will need to perform this operation several times at once; control the degree of tension. If there are no problems when tensioning it, we can conclude that the spring is not functioning correctly.

The spring, which is responsible for the tension of the thread, does not press well. Therefore, it is not pressed well. Identifying this error is extremely simple. The foot is moved to the lower position, the thread is threaded into the eye of the needle and pulled up. Next, the foot is raised again, lowered and the thread element is pulled through. You will need to perform this operation several times at once; control the degree of tension. If there are no problems when tensioning it, we can conclude that the spring is not functioning correctly.- Excessive tension. It happens that the thread is stretched exactly like a string.This is clearly seen when stitching along the bottom thread element. The stitching will be sloppy and not straight enough. In this situation, it is necessary to adjust the lower thread element and, of course, its tension.

- The lower thread element is thicker than the upper one. If you don't already know, it is the top thread element that, so to speak, sets the rhythm throughout the entire line and it determines the bottom line. To make the seam neat, the bottom thread must be selected carefully, it must be sufficiently stretchable. This determines the reliability of your sewing equipment, as well as the quality of sewing.

Where to put the top thread

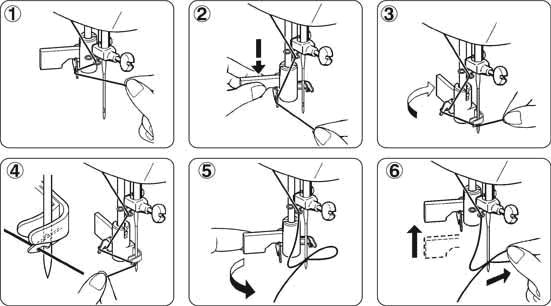

To thread, you will need to raise the foot to press the fabric, then you need to move the wheel a little and move the needle to its highest position. You can work on the equipment no earlier than the upper thread is threaded.

The refueling algorithm is as follows:

- Place the bobbin on the rod, you can see it from above.

- Grab the edge of the thread and pull.

- Insert the edge into the upper eyelet for threading. Thanks to this stage, the thread will be adjusted during operation.

- Place the thread from below into the eye located on the thread guide, and then move on to the needle.

If you do not complete at least one of the steps, be prepared to have to rethread the thread. Please note that for proper operation a certain angle of the thread must be maintained.

What to do if your equipment is not new?

Many needlewomen have old-style sewing machines in their homes. Some people inherit this technique from their mothers or grandmothers, but not everyone knows how to work with it, and the instructions for use have long been lost.They cope well with the tasks assigned to them and all that remains is to figure out how to thread the thread into a manual sewing machine.

The non-old type technique has a similar thread drawing pattern. The difference lies in how the thread is used to fasten it on the machine.

IMPORTANT. The thread in the needle is threaded into a groove, it is located along the needle. You can determine it by running your finger along the needle.

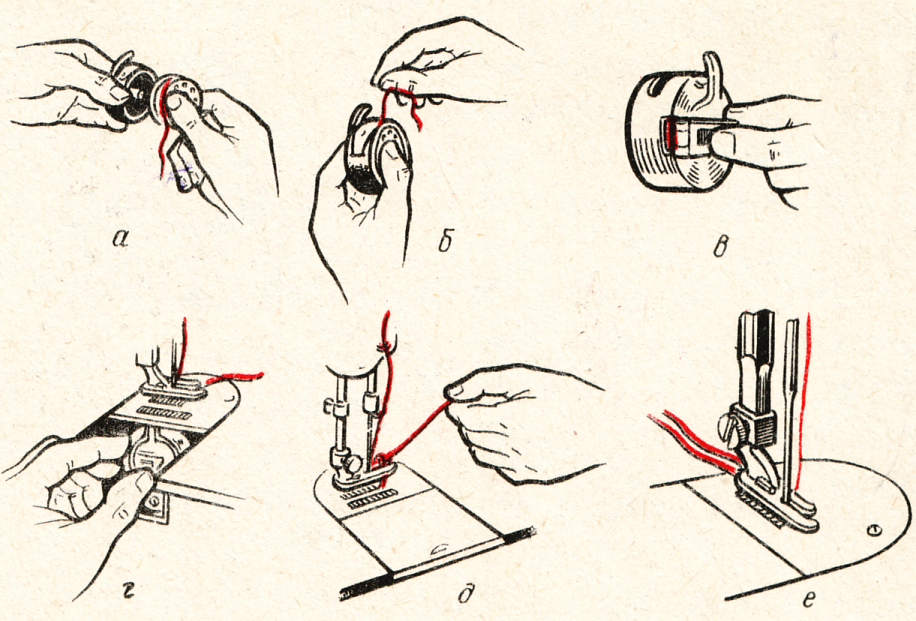

The equipment must be refueled according to the diagram shown on the cover. Rotary machines have their own scheme, because these are old-style units.

The algorithm for refueling an old car is as follows:

- Secure the reel.

- Very carefully thread the thread element into the tensioner, which is located on top.

- Pull it out through the spring. It looks like a hook.

- Thread the thread into the thread guide; it also has a hook for this.

- Now all that remains is to go to the needle clamp.

This type of technique uses a fork; it allows you to throw the thread over yourself.

What to do with the bobbin?

REFERENCE. First of all, it is worth noting that the thickness of the thread that is installed in the bobbin should be one size thinner.

Before threading the bobbin, you should check whether it fits the bobbin case. To do this, you need to place it in the cap, and do not forget about the need to follow the direction of the wound thread. Its tip should be threaded into the tension regulator. Pay attention to how the bobbin rotates; it should not move jerkily. The movement should be smooth.

REFERENCE. The bobbin case is one of the most important parts of a sewing machine and must always be maintained in perfect condition. There should be no chips or damage to its surface.