How to lubricate a sewing machine

Old, long-lived household machines are good in everything except speed. But it is compensated by its enviable wear resistance - even if the owners are too lazy to maintain it properly, the equipment, albeit with a creak, will continue to work. After lubrication, it’s “like new” again. Modern high-speed “electric trains” can do more, work faster, and break down if their components are not treated with oil in time. Let's consider which components and parts need lubrication and what can be used to lubricate them.

Old, long-lived household machines are good in everything except speed. But it is compensated by its enviable wear resistance - even if the owners are too lazy to maintain it properly, the equipment, albeit with a creak, will continue to work. After lubrication, it’s “like new” again. Modern high-speed “electric trains” can do more, work faster, and break down if their components are not treated with oil in time. Let's consider which components and parts need lubrication and what can be used to lubricate them.

The content of the article

An important stage of operation is caring for the sewing machine: cleaning and lubrication

REFERENCE. Old models with a mechanical drive (hand or foot) are reliable and easy to maintain.

The fairly hermetically sealed case does not let the ubiquitous threads and dust inside, and for lubrication there are special holes in the head of the machine - a couple of drops of oil in each and you're done. To clean and process the lower nodes, you just need to turn it on its side - then everything becomes clear on an intuitive level.

There are no problems with the shuttle either - remove the bobbin with the holder and off you go. The only thing that owners of “foot” and “manual” versions systematically forget about is the lubrication of the drive units: the place where the handle meets the flywheel or the pedal meets the drawbar.But the appearance of a characteristic creaking noise will quickly orient the forgetful and even tell you where to lubricate your assistant. With electric models, everything is a little more complicated.

How to lubricate a sewing machine

Modern technology differs from old technology in its body, location and complexity of components. In the operating instructions for electric sewing machines, a whole chapter is dedicated to maintenance. But often a useful book is lost or sometimes simply not translated into Russian. In this case, a universal recommendation will be useful:

the machine is disconnected from the network after bringing the needle to the starting (upper) position;

the machine is disconnected from the network after bringing the needle to the starting (upper) position;- all threads are removed and the shuttle is removed;

- the attachment points of the end and top panels of the housing are determined;

- use a screwdriver to unscrew the screws (it is advisable to mark them to facilitate subsequent assembly);

- the housing is removed and the components are carefully inspected.

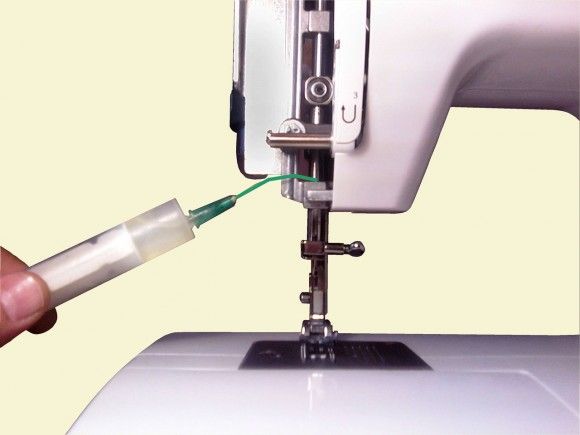

The further order of work depends on the design features of the model. When performing them, you will need: a piece of lint-free cloth, a hard brush and an oiler or a disposable syringe with oil.

Where to lubricate a sewing machine

Using the material and a brush, it is necessary to remove all contaminants that can be reached. After that, machine oil is applied to the moving parts. During processing, it is necessary to rotate the flywheel - this will ensure complete lubrication.

REFERENCE. Plastic gears are not lubricated.

The next step will be cleaning the dirt:

- needle plate;

- teeth;

- paws;

- shuttle node.

After removing any remaining lint and dust, the shuttle assembly is lubricated with a few drops of oil. The remaining elements are simply cleaned with a brush and wiped with a dry cloth.The final stage is reassembling the sewing machine. Before starting operation, it is recommended to “run” it on an unnecessary piece of material to remove any remaining lubricant.

How to lubricate a sewing machine

For these purposes, it is recommended to use household machine oil. It is quite liquid in order to penetrate tight-fitting knots. The second advantage is that this substance does not dry out for a long time, which makes it suitable for lubrication before “preservation” (sending for long-term storage). Well, the main thing is that even if you overdo it a little, the excess that gets on the fabric can be easily removed.

REFERENCE. Experienced seamstresses, especially those who constantly use mechanics, can sometimes recommend kerosene or vegetable oil as an alternative. This option is permissible only as a one-time promotion and only under the condition that the mechanically driven sewing machine is constantly working (you shouldn’t mock electric ones like that - they won’t stand it).

The use of these substances is an emergency measure in a situation where there is an urgent need for lubrication, but household oil is not at hand. The fact is that vegetable matter is prone to drying out, which occurs much faster when heated. Therefore, it is prohibited for use in electrically driven sewing machines - at high speeds the units heat up. In addition, this oil collects and retains dust very well. And we are not talking about the aesthetic side of the issue - dirt spoils the components, leading to their wear and tear. Kerosene is too liquid to provide a long-lasting effect. And after using it, you cannot leave the sewing machine unattended - it will rust. When sent for long-term storage, it will completely fail.If you run out of household motor oil and for some reason you can’t buy it, the smartest thing to do would be to contact the car owner. In his garage it is usually easy enough to find the coveted bottle with the SAE mark. The numbers following this designation indicate the viscosity of the oil.

The use of these substances is an emergency measure in a situation where there is an urgent need for lubrication, but household oil is not at hand. The fact is that vegetable matter is prone to drying out, which occurs much faster when heated. Therefore, it is prohibited for use in electrically driven sewing machines - at high speeds the units heat up. In addition, this oil collects and retains dust very well. And we are not talking about the aesthetic side of the issue - dirt spoils the components, leading to their wear and tear. Kerosene is too liquid to provide a long-lasting effect. And after using it, you cannot leave the sewing machine unattended - it will rust. When sent for long-term storage, it will completely fail.If you run out of household motor oil and for some reason you can’t buy it, the smartest thing to do would be to contact the car owner. In his garage it is usually easy enough to find the coveted bottle with the SAE mark. The numbers following this designation indicate the viscosity of the oil.

REFERENCE. For a sewing machine, it is optimal to use SAE-10W or SAE15W - they are quite liquid. But even if the labeling differs from the recommended one, it will still be better than using “folk” vegetable oil or kerosene.

How often should you lubricate your sewing machine?

There is no universal advice on this matter, because much depends on the intensity of use of the equipment. Typically, an active user is guided by the operation of the machine - it itself “tells” about the need for lubrication with a tighter stroke or extraneous sounds.

For those who have just begun to get acquainted with sewing, the manufacturer recommends quarterly maintenance. But if it is used daily and with a full load, it is advisable to lubricate the machine monthly. In the same case, when the assistant is turned on 1-2 times a week and works no more than a couple of hours, 2 lubrications per year will be sufficient.