How to correctly insert thread into a sewing machine

For beginners, threading a sewing machine can seem intimidating. But once you get used to refueling your machine, you will find that refueling becomes easier each time.

For beginners, threading a sewing machine can seem intimidating. But once you get used to refueling your machine, you will find that refueling becomes easier each time.

The content of the article

How to correctly insert thread into a sewing machine

Correctly inserted thread is the key to successful work. If threaded incorrectly, it will tear and may also damage the fabric. Therefore, follow the instructions to avoid unpleasant consequences and be able to correctly insert the thread into the sewing machine.

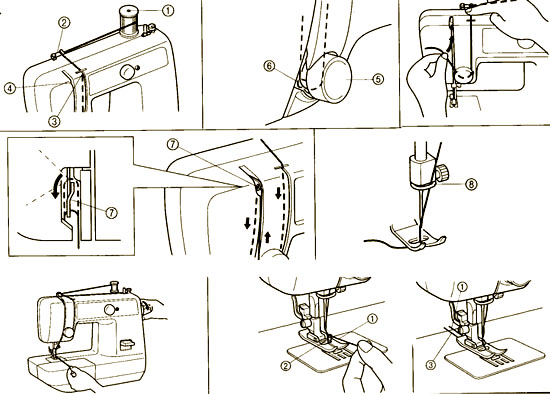

Refueling the upper half of the machine

If your machine has a diagram, you can check it to see where the bobbin pin is located and which direction the fiber should go.

On a note! The spool will be more stable if you position it so that the thread comes out from under the spool when you look down at it.

- Place the spool of thread on the spool pin. The spool is installed on the right side of the machine. This is the larger of the two contacts in this part. Place the fiber on the spool shaft and pull some of that fiber out of the spool.

- Pull the thread through the thread guide on the top of the machine. It looks like a silver piece sticking out from the top.

- Be sure to pull around the back of the guide and towards the front where the U-shaped area for the next thread is located.

- There will likely be instructions printed at the top showing how to pull the fiber through this area.

- Follow the directions on your sewing machine, pulling the thread through the guide towards you. You will loop it around the tension discs at the bottom and then back up towards the top and through the second thread guide. This will all end up creating a long, narrow U-shape with your thread.

- Wrap it around the receiving arm. Once you have completed the U-shape, you will need to wrap the fiber around the take-up arm at the top and then back down to the needle. The gripper arm is a metal piece protruding from the 2nd thread guide. This metal piece will have a hole cut near the top through which the thread can pass.

- Pull the thread back down towards the machine in the direction of the needle. Thread the needle through the small eye in the needle and pull out a few inches of fiber from the other side. Then feed it through the gap in the small metal presser foot directly underneath.

The top half is now primed and you just need to prime the bottom half before you can use the machine

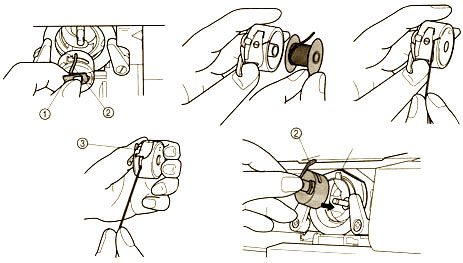

Refueling the bottom of the machine

Remove the cover in the lower compartment. The bobbin case is located under a small overlap, which is either directly under the needle or to the side of it. Look for this camera and open it. This will reveal the bobbin case where you will need to put the threaded bobbin thread.

Important! The compartment cover should be easy to remove.

On some machines, the bobbin case also has a small cover.Make sure you remove it too so that the slot for your bobbin appears.

Next follow the instructions:

- Unwind a few inches from the reel. Before placing the bobbin in its compartment, pull the end of the thread to unwind a few inches from the bobbin. This will be enough to catch when turning the flywheel.

- Make sure you unwind enough thread. A few inches is usually a lot, but if you unwind too little, the thread may not catch.

- Place the bobbin in the compartment under the needle. Check the diagram on the bobbin compartment to see which direction you want your fiber to go. Place the bobbin in the compartment so that the fiber runs in the direction shown in the diagram.

- You should pull the thread to the right so that the fiber unwinds quite easily.

- Close the compartment when the bobbin is in place. Be sure to replace the bobbin case cover.

- The bobbin thread is all hidden under the plate under the needle. To highlight its end, take the round disk or wheel on the right side. Turn it towards you several times and the tip of the thread should pop out. Grab it and pull it until a few inches are exposed.

- If it doesn't snag, inspect the compartment to see if the thread is moving in the right direction and make sure the thread moves easily when you pull it. If it doesn't, it may be full and you may need to unwind part of the stream.

How to thread an old sewing machine

Many people have been familiar with the old machine since childhood, but if you have forgotten how to thread such a spool, follow the instructions.

Place the spool of thread on the spool pin.

Place the spool of thread on the spool pin.- Place the spool holder/cap securely on the spool rim to prevent the fiber from becoming tangled.

- Push the bobbin winder pin to the far left if it is not already there.

- Pass the thread from the spool through the thread guide.

- Pass the end of the thread from the inside through the small hole in the rim of the bobbin.

- Place the bobbin on the pin.

- Push the bobbin winder pin to the right. This will stop the needle from moving.

- While holding the end of the thread, press the speed control to run the machine until the required amount of thread is wound. (Winding stops automatically when the bobbin is full.)

- Cut the thread; push the bobbin to the left and remove it from the bobbin winder pin.

- Trim the fiber from the end of the bobbin.

How to avoid mistakes when refueling

For best results, follow these helpful tips and you'll be sewing like a pro in no time.

Always clean and lubricate the machine thoroughly before starting the machine.

Always clean and lubricate the machine thoroughly before starting the machine.- Use quality fiber to avoid lint in your machine.

- Change your sewing machine needle regularly.

To begin with, strictly follow the suggested instructions, and after a few threadings you will be able to handle the thread without prompting.